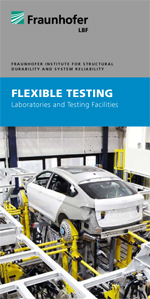

Variable test setups:

- Servohydraulic actuators for test loads from 5 to 2500 kN and torsional torques of up to 64 kNm (> 200 hydraulic actuators, 330 load sensors, strain sensors)

- Various electrodynamic vibration exciters (shakers) for load ranges from 20 N to 27 kN (RKV) and a frequency range of up to 15 kHz

- Internal pressure test equipment for up to 750 bar

- Development of innovative drive systems for special mechanical test setups

- Test equipment for active systems in the power train (VaSA)

- Integration of internal-combustion engines in complex test setups

- Test rig and grips design and specimen production to customers' specifications

Fraunhofer Institute for Structural Durability and System Reliability LBF

Fraunhofer Institute for Structural Durability and System Reliability LBF