Intelligent sensor function, vibration reduction, damping

Intelligent suspensions using metal cushions with integrated sensor function

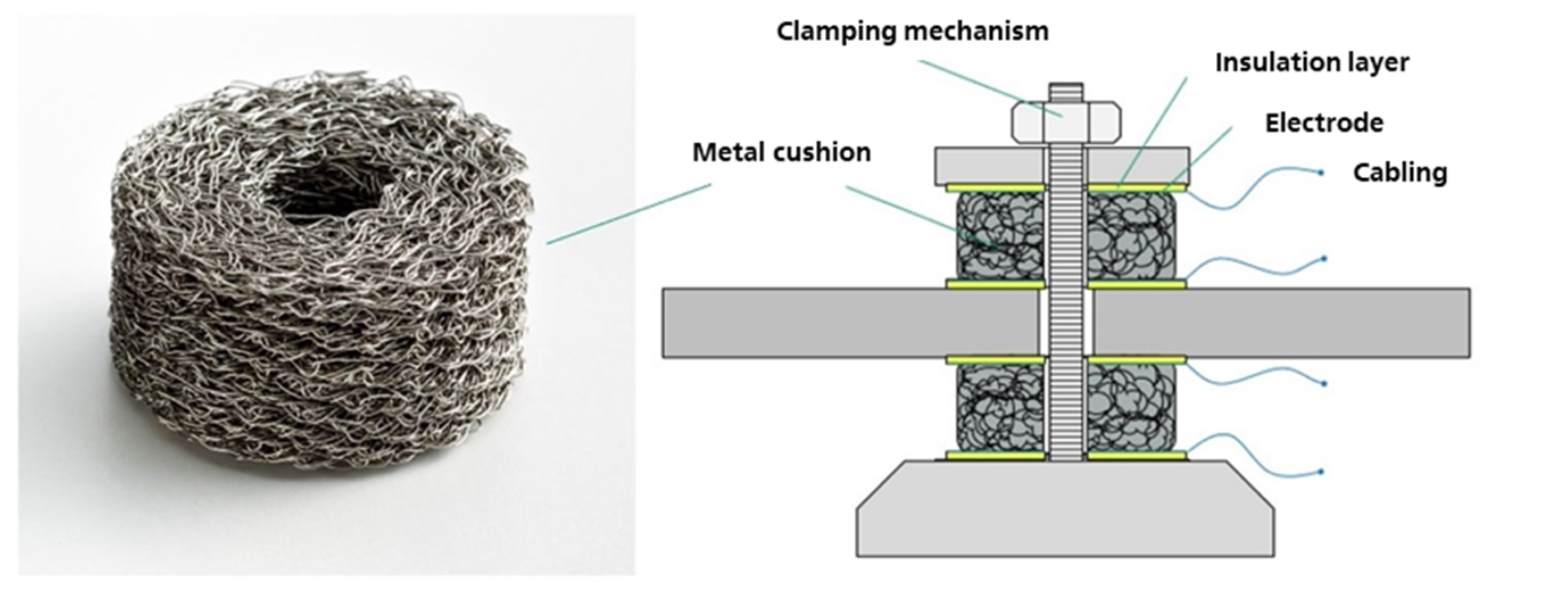

With their high chemical and thermal resistance, metal cushions are a sensible alternative to elastomer components. The elasticity and damping of the wire mesh is based on the interaction of individual wire segments during deformation - a mechanism that is also reflected in the change in electrical properties. Researchers at the Fraunhofer Institute for Structural Durability and System Reliability LBF have harnessed this effect in the form of a new sensor concept. The new sensor technology can be integrated into existing systems in a cost-effective and space-neutral manner and directly detects vibrations and loads. Processes and bearing conditions can be monitored and dynamic bearing forces quantified with simple means. Applications in vehicle and mechanical engineering as well as in measurement and testing technology are conceivable

Customized sensors for unique function integration

While the mechanical properties of elastomers are characterized by macromolecular interactions, it is the support and friction of interwoven wire segments that give metal cushions their elasticity and damping properties. Wire diameter, material and weave density influence the formed parts according to specific requirements. In addition to their elastomer-like behavior, metal cushions are characterized by their excellent resistance to aggressive media, extreme temperatures and aging effects. For this reason, they have established themselves in chemically and thermally demanding vibration technology applications and open up new perspectives where conventional elastomer components reach their limits.

One property of metal cushions that has received less attention to date is their electrical conductivity. It varies with the state of deformation, which influences the number and pressure of the contact surfaces inside the wire mesh. Measuring the conductivity respectively the electrical resistance allows conclusions about the deformation of the bearing element and the forces prevailing within it. Based on this idea, an interdisciplinary team at Fraunhofer LBF has developed a novel sensor concept in which metal cushions, in addition to their traditional role as structural elements, also enable vibration analysis and the determination of static and dynamic bearing forces. The successfully obtained patent underlines the uniqueness of this innovative concept of function integration.

Intelligent metal cushion detects damages efficiently and precisely

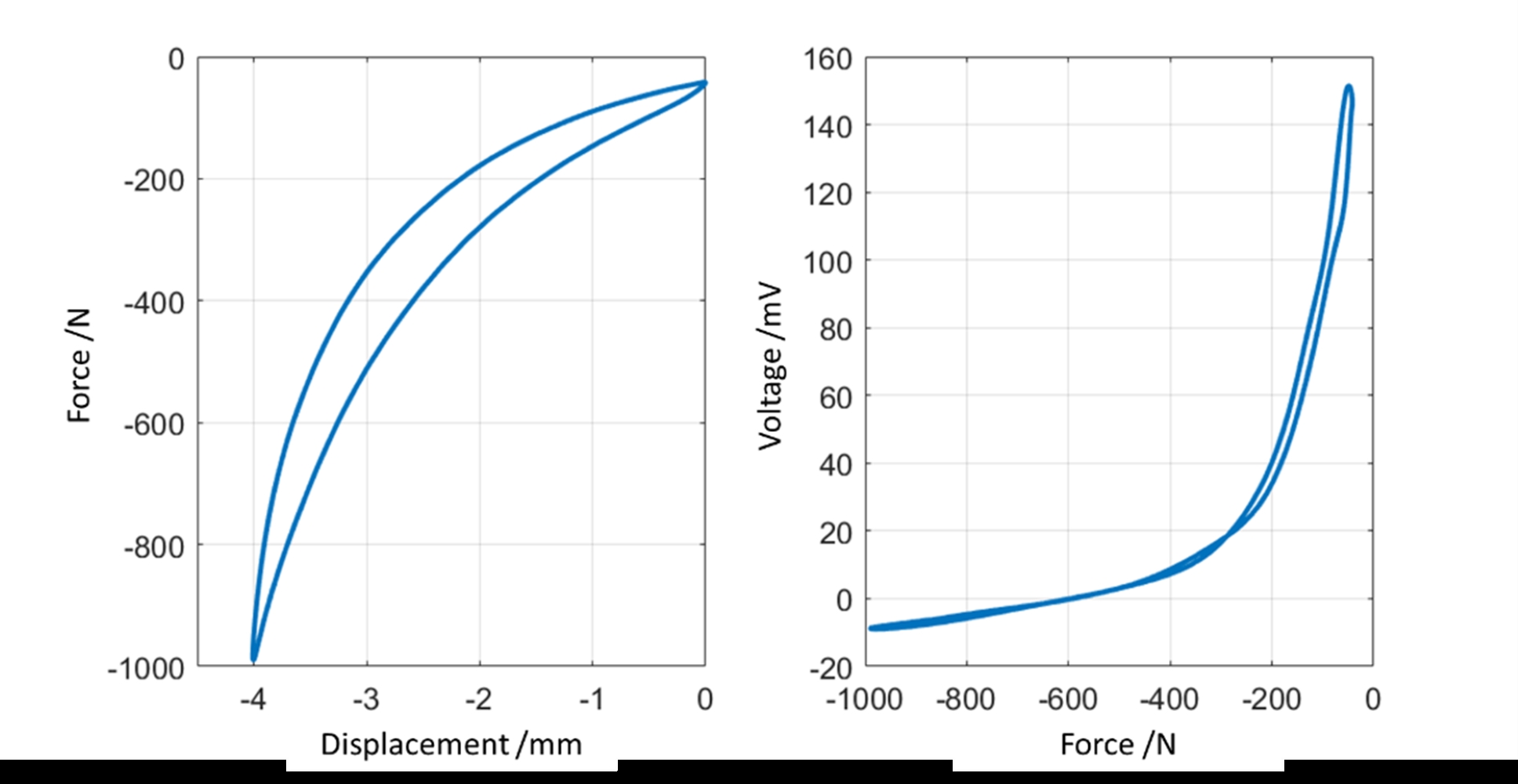

The prototype implementation was accompanied by static and dynamic characterizations of various metal cushions. Thanks to their extensive experience in sensor development and experimental analysis of bearing components and with the help of comprehensive measurement technology, the researchers in Darmstadt were able to systematically investigate and optimize the sensory effect. Simple measuring instruments are sufficient to accurately resolve vibrations with frequencies of up to 50 Hz. The non-linear sensor characteristic curve, which is related to the strongly progressive mechanical hysteresis, can also be described mathematically with very good correlation, whereby both displacement and force can be represented as measured variables.

The possible applications of the sensor concept extend across various industries related to vibration technology. A particular advantage is that existing systems based on metal cushions can be supplemented with the sensor technology in a cost-effective and space-neutral manner, which leads to an efficient use of existing resources and easy-to-implement digitalization. The functional interation makes it possible to meet the high demand for structural-dynamic data, which provides valuable information about machine states and processes, with practical means. Furthermore, the precise measurement of loads and the detection of misuse situations identifies potential damage to entire systems and the metal cushion itself at an early stage and helps to prevent it.

Last modified:

Fraunhofer Institute for Structural Durability and System Reliability LBF

Fraunhofer Institute for Structural Durability and System Reliability LBF