Fraunhofer LBF is equipped with measurement stations for dynamic mechanical analysis (DMA), which can be used to determine the right choice of material, assist in product development and service life time prediction of elastomers. Frequency and time independent measurements of the dynamic shear modulus and modulus of elasticity can be executed at a temperature range between -120 °C and 300 °C. These measurements can be complemented with ultrasound examinations in the megahertz frequency range. Under assumption of the frequency-temperature-equivalence, master curves of storage modulus and loss modulus can be created. Besides dynamic experiments, relaxation and retardation experiments are also possible. By adjusting the measurement data to material models, the input parameters for FEM simulations can be provided. The modulus value of the rubber plateau allows statements regarding the cross-link density.

A special feature of DMA measurements is the capability of carrying out the tests in organic liquids (e.g. oils or fats) or under defined humidity. Further applications of DMA are found on a separate page.

Dynamic Mechanical Analysis of Elastomers

The viscoelastic properties of elastomers can be determined independently of temperature and frequency with dynamic mechanical analysis. Usually either the complex modulus of elasticity (E*=E‘+iE‘‘) or the complex shear modulus (G* = G‘ +iG‘‘) is measured.

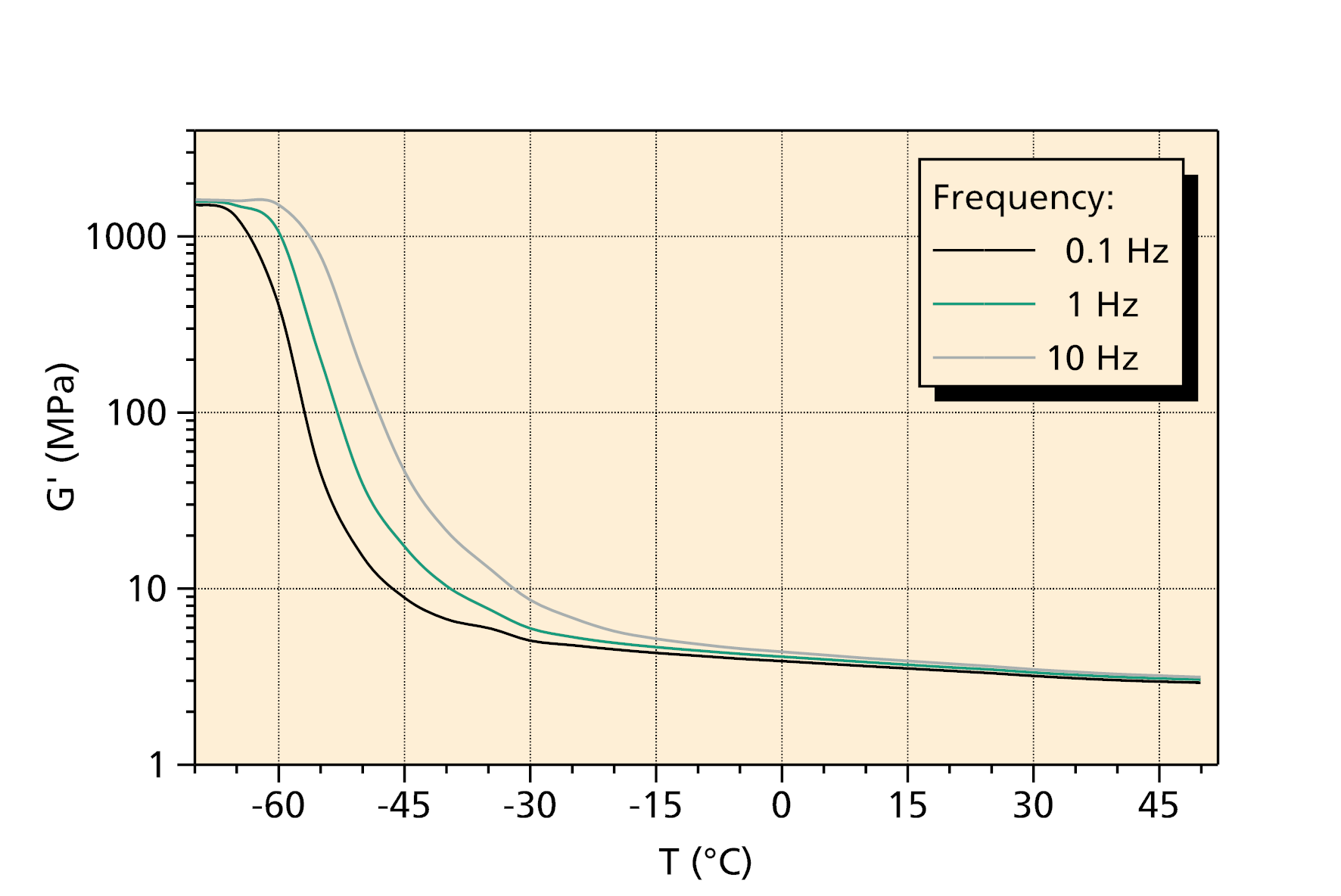

The figure above shows the time dependency of the real component of the shear modulus G‘ of a soot filled elastomer at measurement frequencies between 0.1 Hz and 10 Hz. The glass transition is characterized by a significant decrease of the shear modulus with increasing temperature. Since the glass transition is a dynamic phenomenon, there is also a significant dependency on the measurement frequency for the glass transition, seen for example in the figure at -56 °C at 0.1 Hz to -51 °C at 10 Hz.

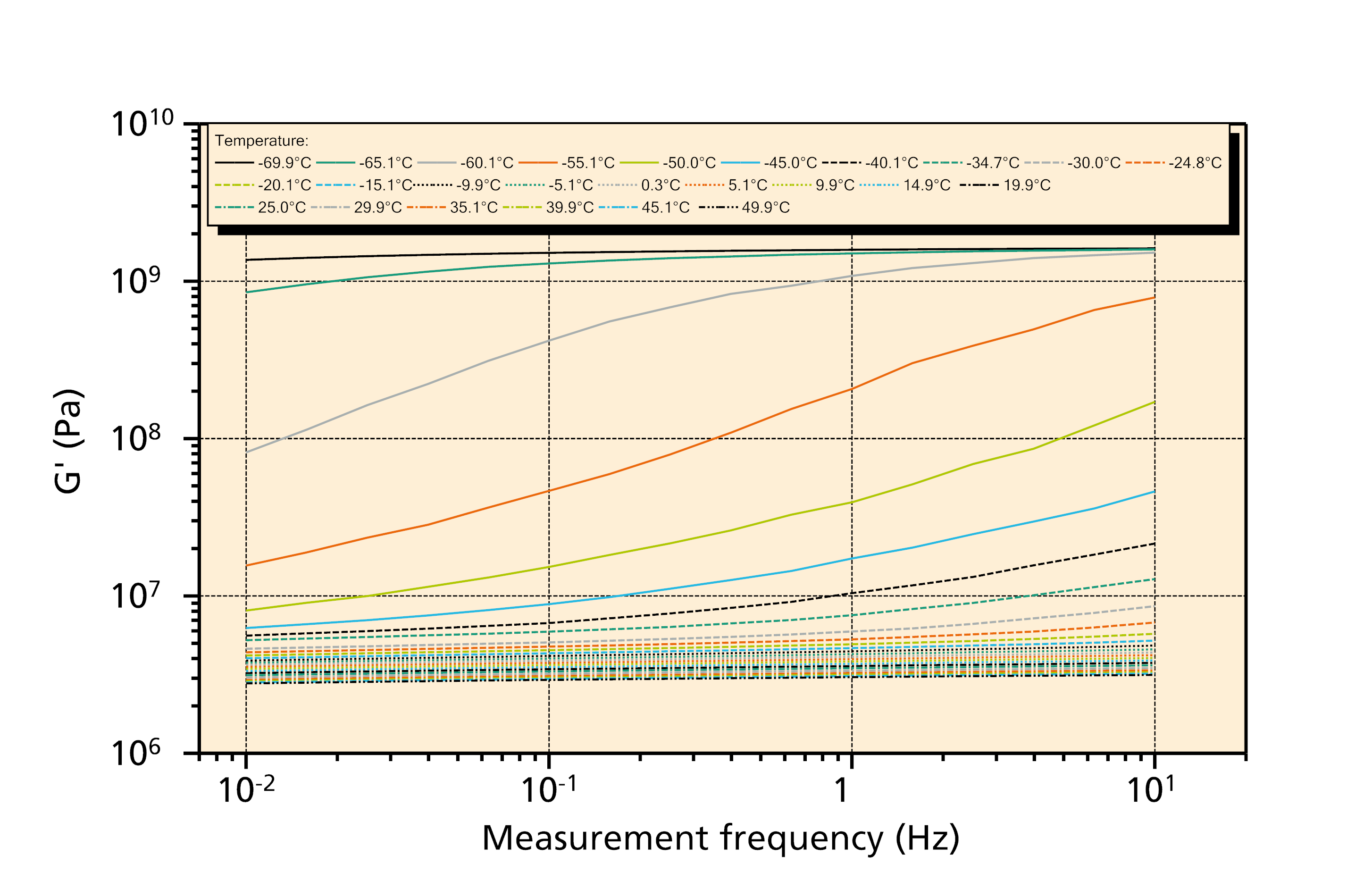

Another measurement possibility is given by measuring the modulus in dependency of the testing frequency at defined a temperature. The lower figure shows the real component of the shear modulus G‘ of a soot filled elastomer at measurement frequencies between 0.01 Hz to 10 Hz. It was measured at temperatures ranging from -70 °C to +50 °C in 5 K increments. In the range of the glass transition temperature (-55 °C), the shear modulus shows a significant dependency on the measurement frequency. Contrary to this, outside the range of the glass transition (e.g. -70 °C or +50 °C), the modulus is only to a small degree dependent on the measurement frequency.

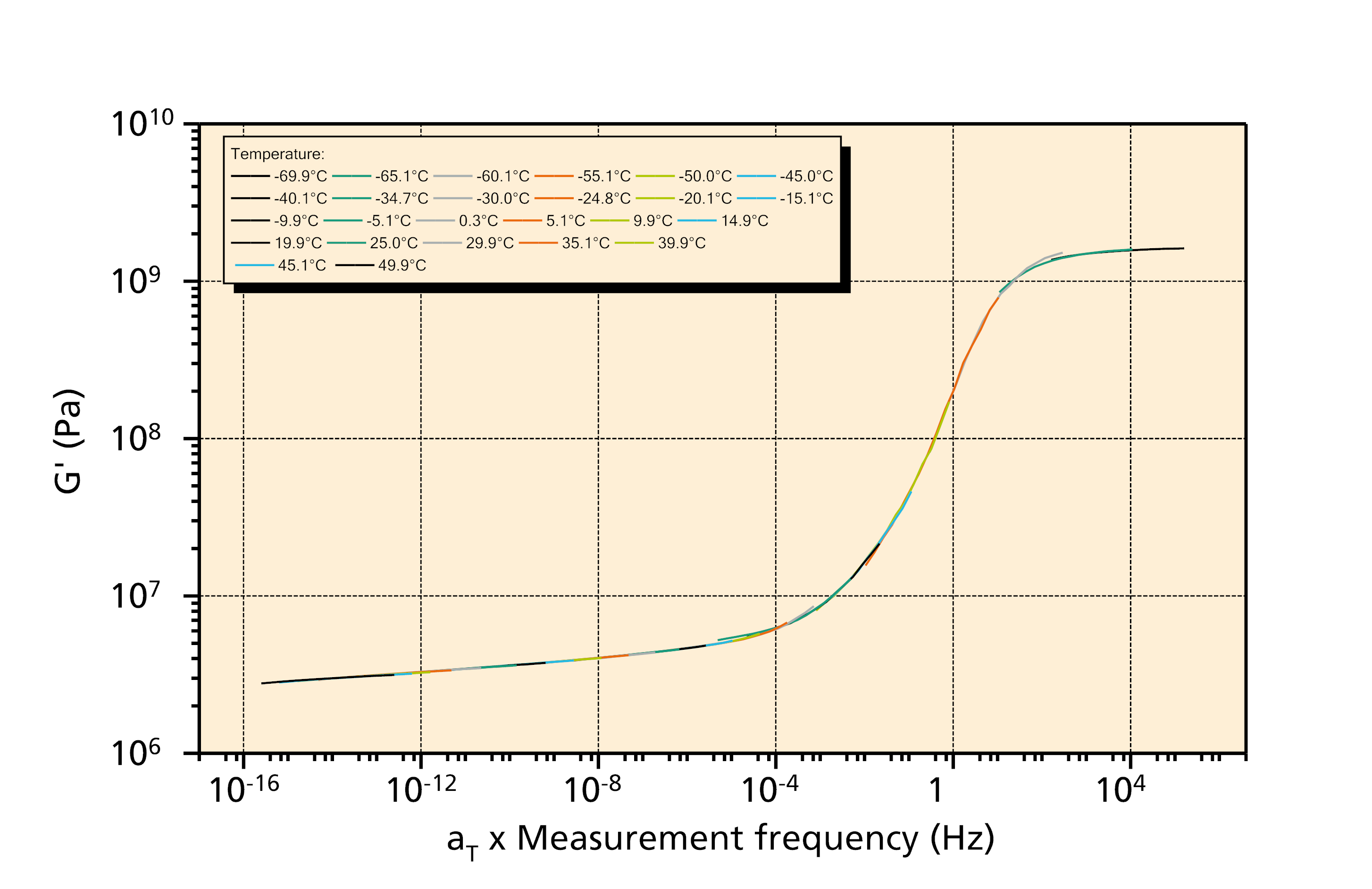

The frequency dependent shear modulus curves, measured at single temperatures, can be combined to one so called master curve. For this, the single curves are shifted along a logarithmic frequency axis, so that they result in a relatively smooth shear modulus curve (see figure above). Every individual curve is shifted along the frequency axis with a different displacement factor aT. One curve is not displaced. This curve and it´s respective temperature is called reference temperature. In the figure, the reference temperature is -55 °C. The master curve represents the frequency dependency of the modulus at the reference temperature in a much broader frequency range, than it is achievable with this measurement technology. One needs to keep in mind that a master curve construction is possible for many types of polymer, but not for all. The principle of frequency-temperature-superposition must apply.

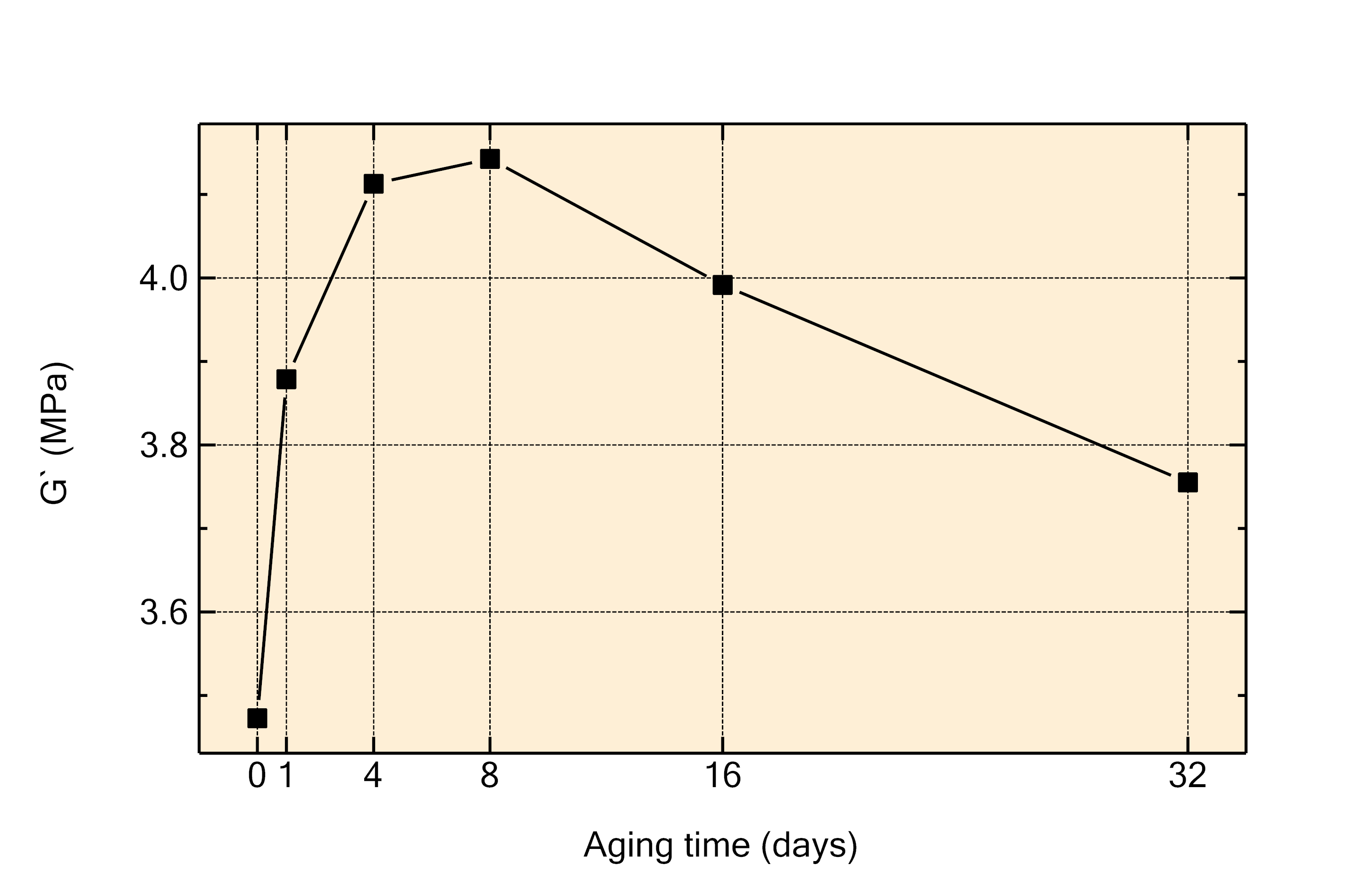

The measurement of the shear modulus is a possible way to characterize the aging of elastomers. The lower figure shows the change in the shear modulus value of a soot filled elastomer (measurement temperature: 50 °C, frequency 1 Hz) in dependency of the aging time. The aging took place in a furnace at 100 °C in normal air atmosphere. The shear modulus of elastomers in the rubber plateau, which is significantly above the glass temperature, is connected to the network node density. Network nodes can be of chemical nature (e.g. sulfur cross-linking), but also of physical nature (adhesion of polymer chains to fillers, chain entanglement). During aging, thermo-oxidative decomposition and the formation of new cross-links are in interaction with each other. The observed increase of the shear modulus in the first few days is ascribed to e.g. chemical post curing. In the further course of aging the decomposition of network nodes is predominant, which leads to a decrease in shear modulus.

Fraunhofer Institute for Structural Durability and System Reliability LBF

Fraunhofer Institute for Structural Durability and System Reliability LBF