Elastomer seals for use in H2 transport

Sealing materials for the transport of hydrogen

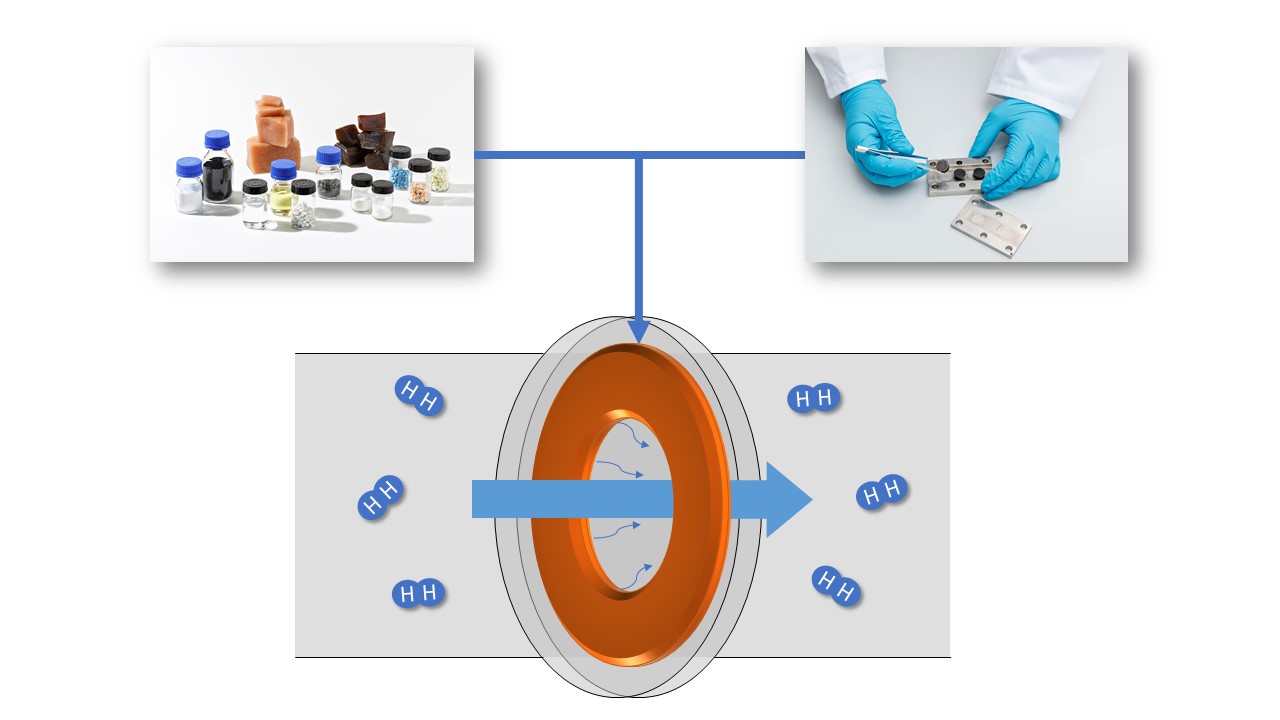

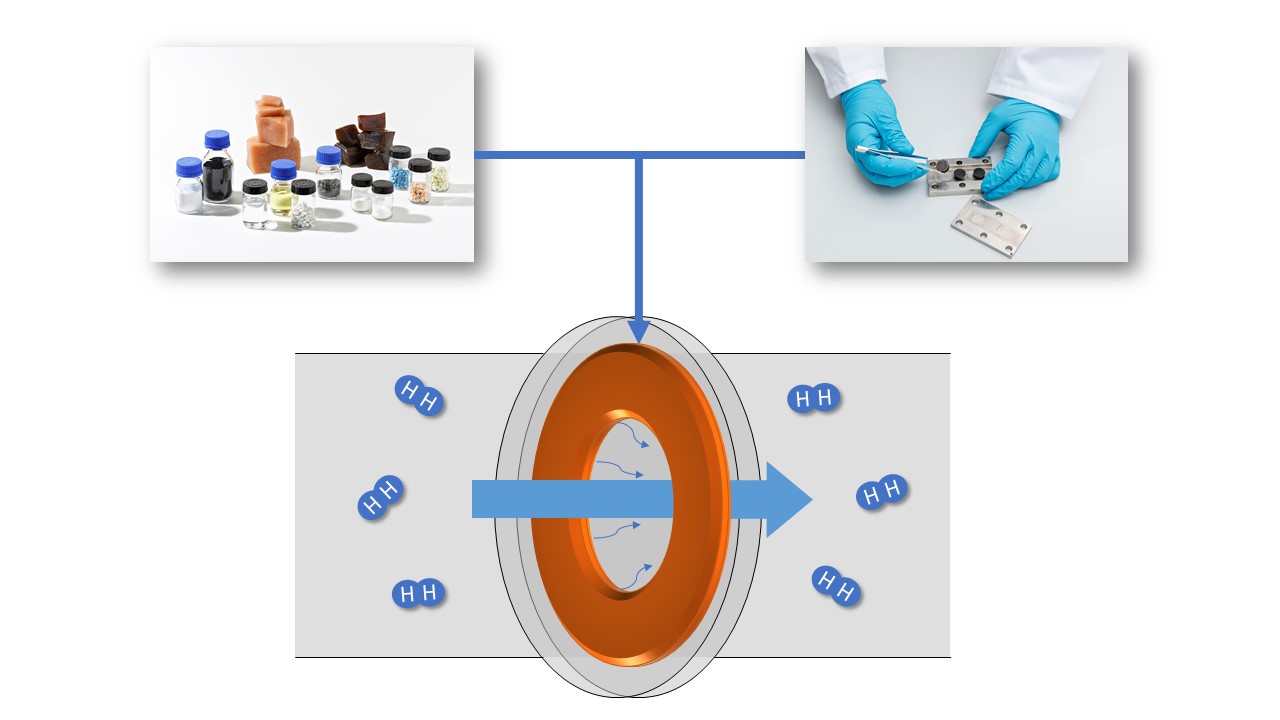

In the course of the energy transition, the use of hydrogen as an energy carrier represents one of the key technologies. Particularly in hydrogen transport and in tank systems for fuel cell vehicles, the highest demands are placed on the sealing materials used, since leakage cannot be tolerated due to explosiveness. The use of elastomer seals is firmly established in the current natural gas infrastructure and thus also represents a key component for hydrogen transport. Elastomer seals are also the focus of attention regarding the continued use of existing pipeline systems for hydrogen, although the medium of hydrogen once again poses special challenges for the sealing elements used.

The system pressure in initial series applications of hydrogen tank systems is 350 bar, with future developments aiming at applications with 700 bar nominal pressure or beyond. In addition to the enormous stresses placed on the seals by the pressure, there are also temperature ranges of -40 °C to 85 °C that can occur during refueling operations. Due to the small molecular size of hydrogen, the migration of hydrogen into and through the sealing elements must also be considered. On the one hand, this leads to swelling of the sealing elements, which must be considered for component design. On the other hand, hydrogen absorbed by the material can lead to abrupt volume expansion in the event of a sharp drop in pressure, which can damage the component so that rapid escape of the gas from the sealing body is possible. In addition to the high demands placed on the nominal properties of the seals, elastomer materials can be expected to experience aging effects over their service life, which change the sealing properties. These effects are also strongly influenced by acting mechanical loads, temperatures and media and must therefore also be considered in the design.

Until now, only a few reliable findings exist on the use of elastomers in combination with hydrogen. The aim of this joint project is to provide a fundamental understanding of the behavior of elastomer seals when used under hydrogen. The aim of the HydroTransSeal project is to understand the interaction mechanisms of hydrogen with elastomer materials and to take appropriate measures to make the materials more robust to permeation, adsorption and swelling when in contact with hydrogen (e.g. by selecting suitable fillers and additives). Currently, hydrogen is still transported primarily by tanker trucks and few pipeline systems exist. It is therefore necessary to evaluate elastomer seals used in existing pipeline systems regarding their suitability for hydrogen transport and, if necessary, to qualify them for use in order to simplify hydrogen transport. By developing a material and aging model, it will be possible to estimate the service life of elastomer materials based on their aging-dependent behavior. In the long term, this will make it possible to optimize the compounds for the area of application. The project should also be an incentive for raw material suppliers in the field of elastomers to place innovative elastomer formulations in the promising field of hydrogen transport and to initiate new developments for these systems.

Focus & approach

The focus of the joint project is on identifying and developing suitable elastomer materials for use in the field of hydrogen transport via pipeline systems and tank trucks. On the one hand, a fundamental understanding of material behavior under the influence of hydrogen is to be developed. On the other hand, the elastomers are to be optimized in terms of sorption, permeation and swelling under hydrogen atmosphere by the specific selection of fillers and additives. In addition, elastomer systems already used in natural gas pipelines are to be investigated for their suitability for use with hydrogen and, if necessary, qualified.

1. presentation of the current state of the literature

- Literature research in the field of elastomers in contact with hydrogen

- Compilation of the already known information in the field of elastomers in contact with hydrogen

2. set-up of a hydrogen aging test and creation of an experimental design

- Adaptation of an experimental setup for hydrogen exposure of samples under selected operating conditions up to 200 bar. Elaboration of an experimental plan in consultation with the partners for the pressure and temperature ranges to be tested

- Estimation of the conditions for a real representation of the service life in consultation with the partners

- Material selection and compounding

- Selection of the rubber base and the crosslinking system for the tests in consultation with the project participants

- Selection of additives and fillers in consultation with the project participants for the development of application-oriented systems

- Determination of the optimum mixing and vulcanization parameters for use under hydrogen

- Selection of existing seals from application in natural gas infrastructure for suitability under the influence of hydrogen

3. model development

- Development of a model for the aging of elastomers under the influence of hydrogen from the obtained mechanical and analytical investigations for the prediction of service life

4. aging under hydrogen and characterization

- Aging of samples under realistic conditions for hydrogen transport

- Analytical and mechanical investigations of the aged samples regarding the influence of the hydrogen impact depending on the components used (rubber, additives, fillers)

- Analytical investigations of the samples under hydrogen influence regarding sorption and diffusion

- Adaptation of the formulations to the findings obtained up to this point

Based on the results, the influence of hydrogen on elastomers is examinated under realistic conditions in hydrogen transport, with the aim of better understanding the interaction of the individual elastomer components in this context. This should result in recommendations for optimizing systems already in use and developing the best possible formulation for seals in hydrogen transport.