For the development of dielectric elastomeric materials, dielectric actuators (DEA) and sensors as well as generators, Fraunhofer Institute for Structural Durability and Systems Reliability LBF has a wide array of tailored testing procedures. These range from the electrical, mechanical and electromechanical material characterization to high frequency vibration resistance testing up to service life time predictions. The knowledge and material data flow into material and part development as well as the simulation of dielectric converters.

Characterization of Dielectric Elastomers

Tabbed contents

Material Characterization

In the plastics division of Fraunhofer LBF different test methods for determining material properties of dielectric elastomeric materials are available. With these specialized test methods, frequency and temperature dependent mechanical, electrical, and electromechanical properties of dielectric elastomeric materials are determined. For example, the electromechanical coefficient can be calculated from frequency and temperature dependent measurements of mechanical moduli and permittivity. With the help of these specialized methods, the mechanical, electrical, and electromechanical failure of a component can be monitored in long-term tests. A special aspect are examinations of the influence of humidity on the material properties.

The frequency and temperature dependent material values can be adjusted with material functions and depict the requirements for numeric simulations.

Characterization methods for dielectric elastomers include:

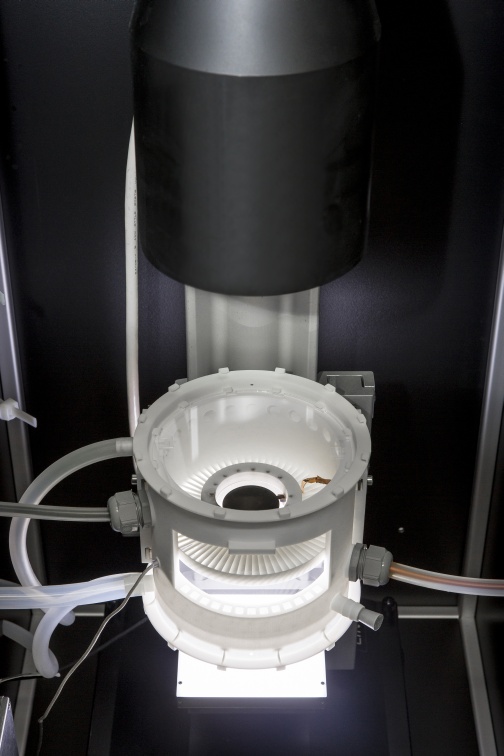

Dielectric spectroscopy

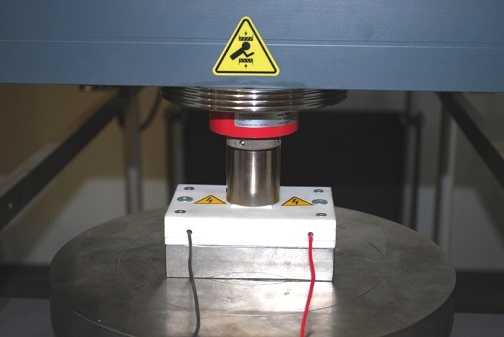

High voltage testing

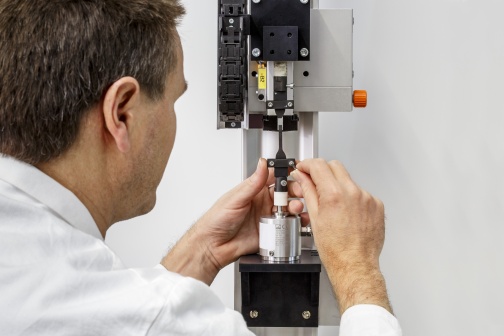

Dynamic mechanical analysis

Tensile tests

Electromechanical characterization

High frequency vibration resistance tests

Electrical and electromechanical aging

Elastomeric Converters

The Fraunhofer Institute for Structural Durability and System Reliability LBF has many years of experience in the field of dynamic characterization of dielectric elastomer transducers, which can be used as actuators, sensors, or generators. Measurement methods developed specially for this task can characterize the mechanical, electrical, and electromechanical properties of the converters, independently from frequency, load or tension. Special attention lies on the typical non-linearity of such converters. Additionally, long-term tests to examine the reliability can be conducted at different temperatures. The several, multi physical examinations are a substantial part in the integrated development and interpretation of dielectric elastomer transducers. The data gained through experiments can also serve as a basis for the creation of parametric numeric models.

Since the field of dielectric elastomeric transducers is rather new, standardized measurement methods do not exist yet. Fraunhofer LBF collaborates on the creation of the first guidelines for the characterization of dielectric elastomeric transducers. For this, electrical, mechanical and electromechanical properties are determined with defined electrical and mechanical boundary conditions and are described in the frequency and time range. If needed, these examinations can be conducted dependent on the temperature.

[1] F. Carpi, I. Anderson, S. Bauer G. Frediani, G. Gallone, M. Gei, Ch. Graaf, C. Jean-Mistral, W. Kaal, G. Kofod, M. Kollosche, R. Kornbluh, B. Lassen, M. Matysek, S. Michel, S. Nowak, B. O’Brien, Q. Pei, R. Pelrine, B. Rechenbach, S. Rosset, H. Shea, Standards for dielectric elastomer transducers, Smart Materials and Structures 24 (10) (2015)

Some typical metrological connections include:

Actuator deflection at different mechanical preloads

Actuator force in fixed conditions

Quantification of the electromechanical non-linearity

Capacity in dependence of preload and/or deflection

Actuator deflection at a specific frequency or cycle number

Quantification of non-linearity or harmonic distortion factor

Fraunhofer Institute for Structural Durability and System Reliability LBF

Fraunhofer Institute for Structural Durability and System Reliability LBF