By increasing the radiation intensity during artifical weathering, material properties can change faster and damage can occur after shorter weathering periods. This enables faster and more cost-effective weathering tests.

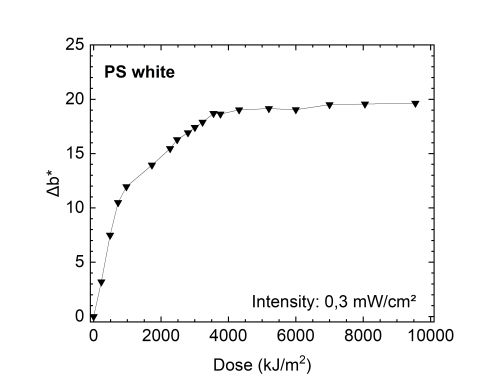

If the radiation intensity is intensified, it must be ensured that the material properties essential for the product change proportionally with the UV‑dose. By weathering plastic products with different radiation intensities – e. g. with 60 W/m², 120 W/m² and 180 W/m² - the proportionality between UV‑dose and changes in properties can be tested.

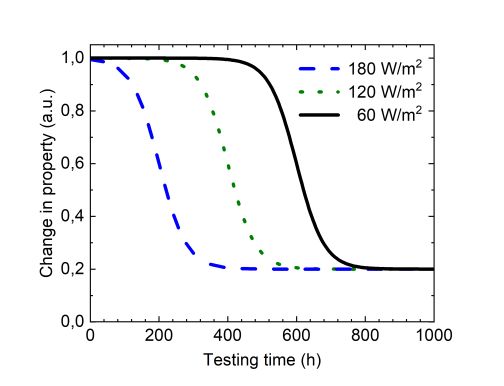

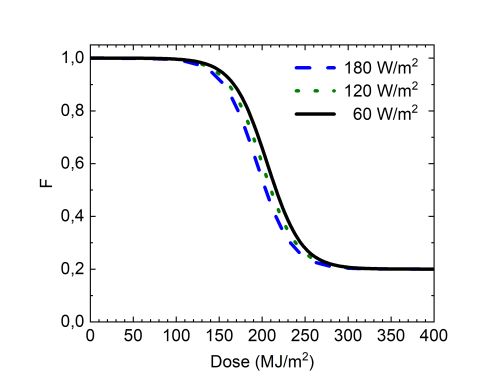

The upper figure shows schematically the decrease of a material property – for example gloss or tensile strenght – for arbitrarily chosen different radiation intensities. In this example, the material property changes intensity-dependently with the duration of weathering. The figure below shows the material property as a function of the radiation dose, which is calculated from the product of intensity and time. It becomes clear that the property changes uniformly with the radiation dose, independent of intensity.

If it is proven that the change in properties depends only on the radiation dose (and not on the radiation intensity), the radiation intensity can be increased and thus the duration of weathering is reduced. However, it is recommended that comparative experiments are carried out using standard-compliant weathering and outdoor weathering. If mechanisms other than photodegradation, such as hydrolysis, thermal or thermo-oxidative ageing or stress cracking due to shrinkage or swelling dominate the ageing behaviour of the plastic, an intensification of the radiation intensity does not allow reliable weathering results to be expected. A realistic acceleration can then only be achieved by a more complex approach to optimizing weathering cycles.

Investigations into the meaningful intensification of radiation can be carried out at Fraunhofer LBF for specific plastics and coatings.