Bubble Inflation of Elastomer Sheet: Bulge Test for Biaxial Loading

The results of virtual simulation of elastomer parts often differ significantly from the real behaviour of components. Possible reason is that only data from unidirectional tensile tests are taken into account. Scientists at the Fraunhofer Institute for Structural Durability and System Reliability LBF have improved known test specifications for the biaxial tensile test. The implemented 3D optical measurement during the loading allows the precise measurement of the mechanical response of the elastomer sheets. The data from new test improves the material modelling thus providing the basis for an enhancement of the design quality of elastomer components.

Modelling based on the tensile test alone is easy but not sufficient for real elastomers. The aim is therefore to provide industry usable information on the mechanical behaviour of elastomers under multi-axial loadings. The bulge test is the simplest way to realize biaxial tensile loadings on elastomer sheets. This method of Fraunhofer LBF supplies data for reliable modelling of components. In this way, parts for automobiles, components in aircraft construction or products for sports, medicine, and household can be designed more reliably and more cost-effectively.

New method improves material modeling

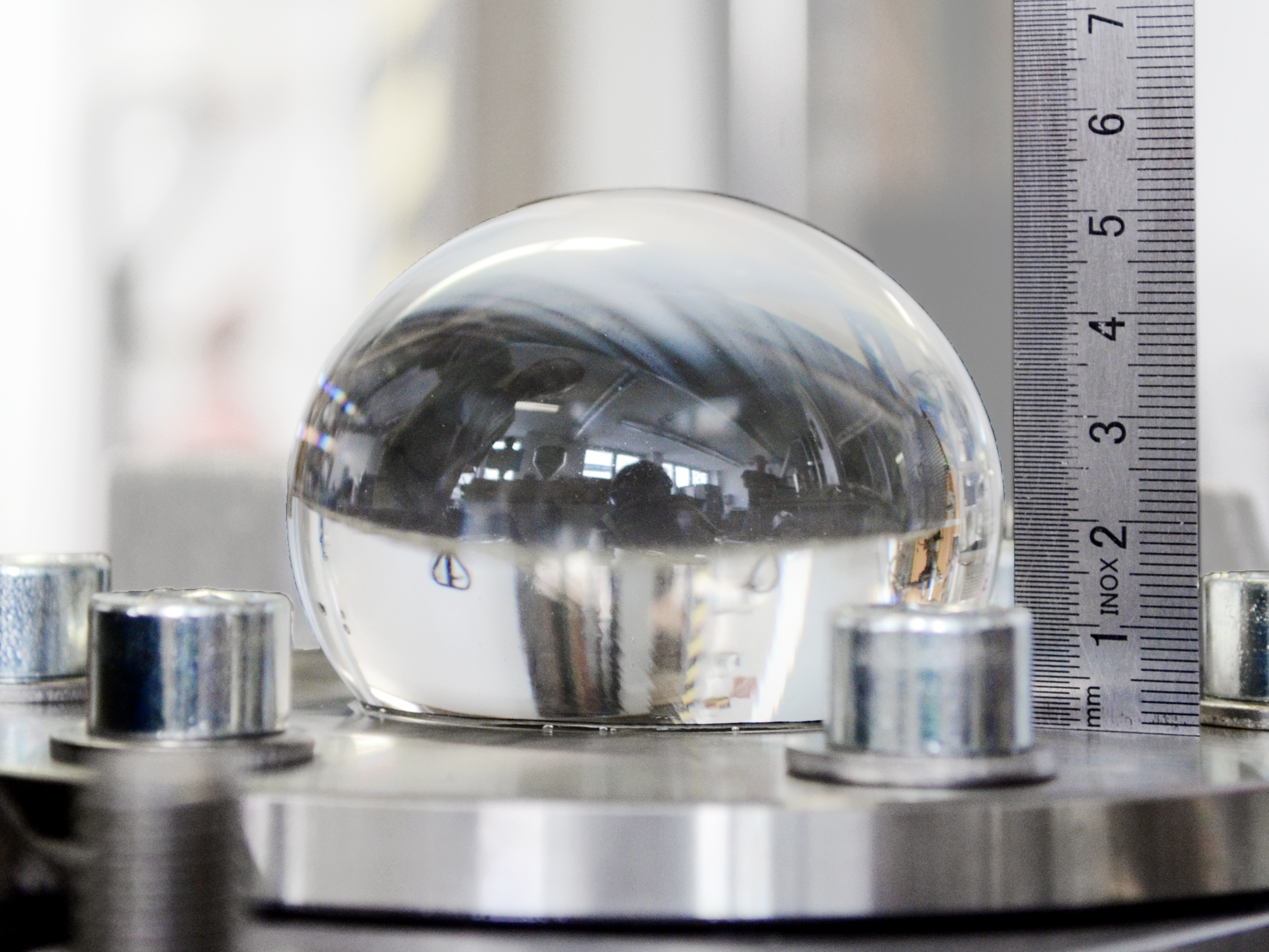

The test fixture consists of a circular ring, an elastomer plate and a base plate. The elastomer plate is clamped in the test fixture and inflated with water, causing it to expand as a bubble. A balanced biaxial stress occurs in the center of the bubble. Stress singularities in the clamping area are avoided by a special design of the edges of the circular ring. To ensure optimum fixation of the plate, the circular ring is centered and carefully bolted on the base plate. The evaluation of the geometry change in the elastomer bubble is performed in a subsequent post-processing step using the GOM Aramis 3D software. The test results can be evaluated up to an approximate height of the bubble of 45 millimeters. Here, the maximum height is set by varying the diameter of the circular ring. The inner diameter of the circular ring of 40 to 50 millimeters is recommended for elastomer plates in order to obtain useful results in the evaluation. An elliptical bore can also be used to obtain additional stress states in the bubble for more in-depth material analysis. Water or alternative fluids are used as the pressure medium. The tests are performed according to customer specifications or standards.

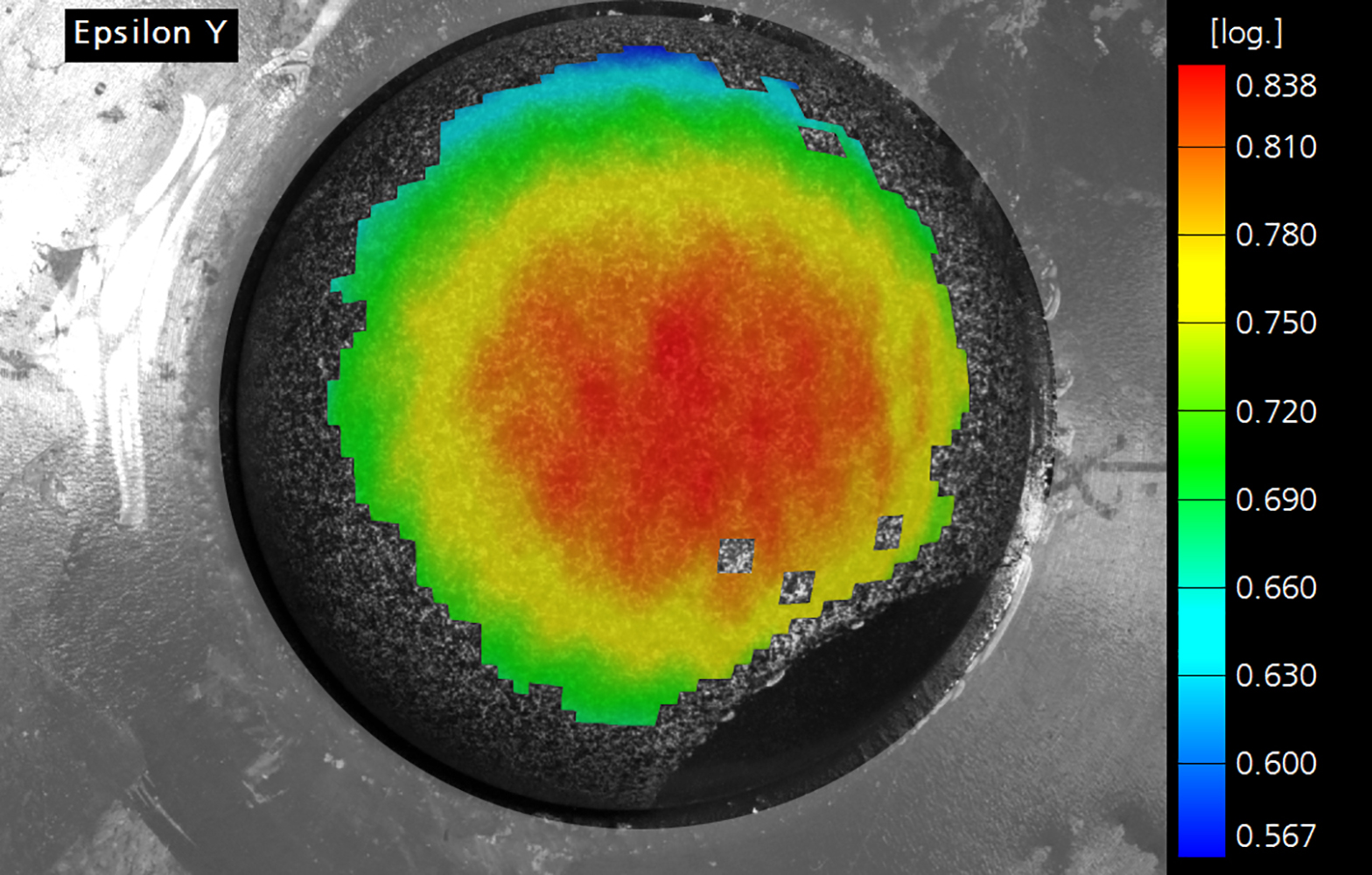

Evaluation of three-dimensional deformation by digital image correlation

Optimal results are obtained for specimens with an external diameter of 110 millimeters. The thickness of the materials is measured before the examination. This measurement is based on a method specially developed at the Fraunhofer LBF, which avoids the induction of stress concentrations in the specimen. The specimen is speckled with a statistically distributed black and white pattern and then tested directly to ensure optimum adhesion between the sheet and the black and white pattern. This allows the evaluation of two-dimensional strains on the specimen surface by digital image correlation as function of pressure. In addition, the setup allows to obtain results on potential stress whitening in an isochoric deformation mode. This is done by inspecting an unpainted spot in the fourth quadrant of the specimen. To obtain data on possible anisotropy of the material, all specimens are mounted in the test fixture in the same position, taking into account their orientation in the sheet. The setup allows the sample to be placed on the base plate without air bubbles, ensuring that the incompressibility assumption for the pressurized media is met. The scientists analyze the individual challenges of modeling elastomeric materials and provide expertise at all levels of the design process.

Last modified: