Fatigue strength of hybrid joined multi-material structures: Fraunhofer LBF identifies high potential for lightweight design

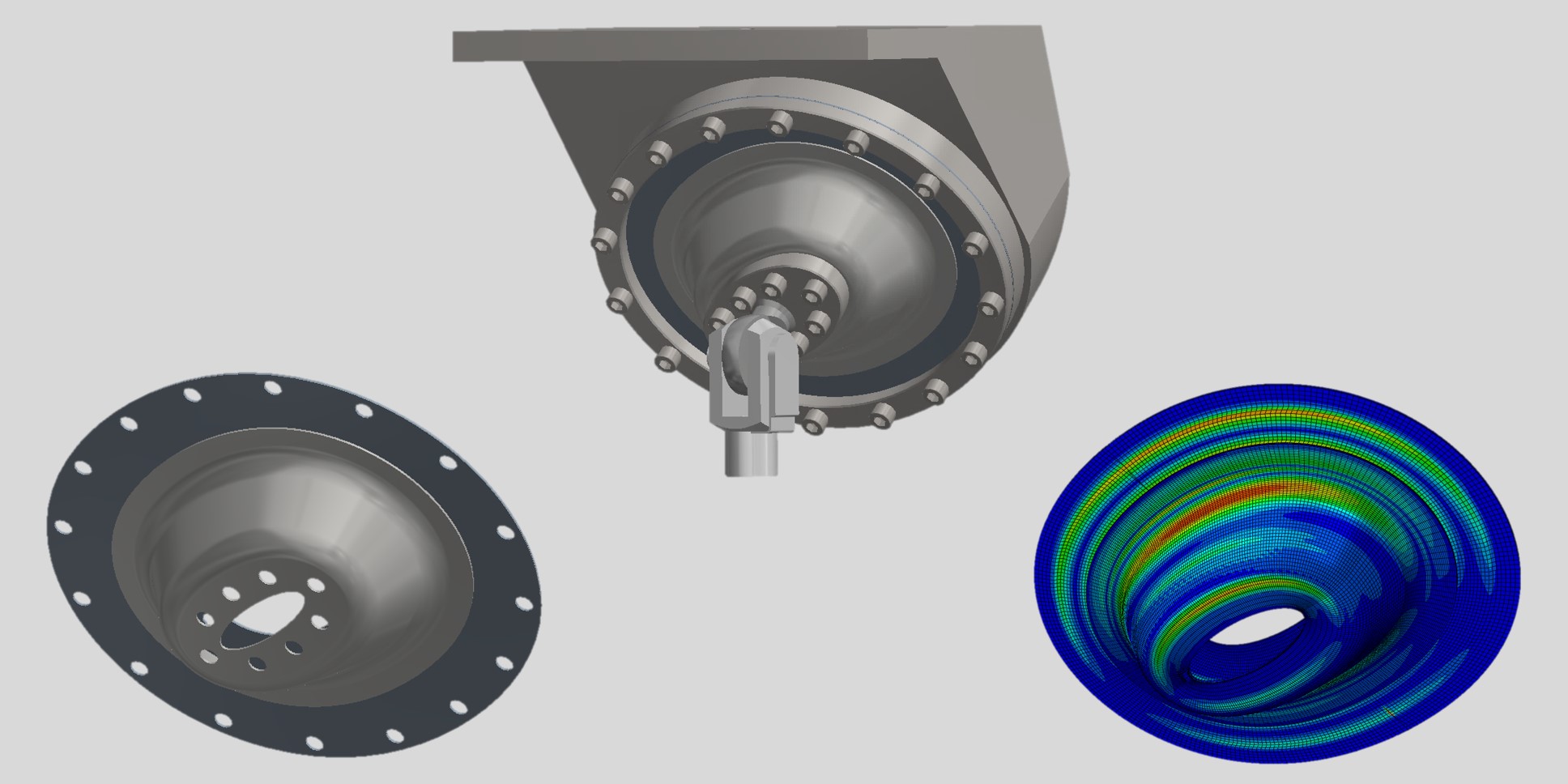

Increasingly stringent statutory emission limits are pushing the automotive industry toward innovative lightweight design solutions. In this context, the fatigue strength of thin sheet metal structures, especially made from multi-material, is becoming increasingly important. As part of the EU-funded research project "ALLIANCE" on the topic of lightweight design and CO2 reduction, the car manufacturer Opel Automobile GmbH, together with the Fraunhofer Institute for Structural Durability and System Reliability LBF and the System Reliability, Adaptive Structures, and Machine Acoustics department of the Technical University of Darmstadt, has developed innovative numerical fatigue strength assessment approaches for multi-material joints based on fatigue tests of hybrid joined shear and peel specimens. The method was validated by Fraunhofer LBF scientists with fatigue tests on component-like bowl specimens with the material pairing Steel-Aluminum.

The use of component-like bowl specimens provides practical insights into fatigue properties of structural components, which cannot be determined in this way on the usual standard specimens with a simple overlap. The fatigue tests serve as a basis for the validation of numerical methods for fatigue life estimation and provide insights into damage mechanisms that occur in real life. The test results from Fraunhofer LBF now offer first insights into the complex world of the fatigue strength of hybrid joined structural components. "The potential of this joining process, especially for future lightweight construction concepts in the automotive industry, is very promising. However, in order to fully exploit it and use its full potential for industrial application, it is imperative to further optimize manufacturing processes," emphasizes Dr. Jörg Baumgartner, who is in charge of the research project at Fraunhofer LBF.

Fatigue properties investigated as close as possible to practical conditions

For the bowl specimen, a deep-drawn bowl is connected to a firmly clamped flat base plate in the area of the formed flange of the bowl. The great advantage is that both forces and moments can be introduced into the bowl in any direction in the test setup and thus a defined stress state (combination of shear and peel stress) can be applied. Thus, this specimen form enables the fatigue properties of structural components to be investigated as closely as possible to practical conditions but still on a laboratory scale.

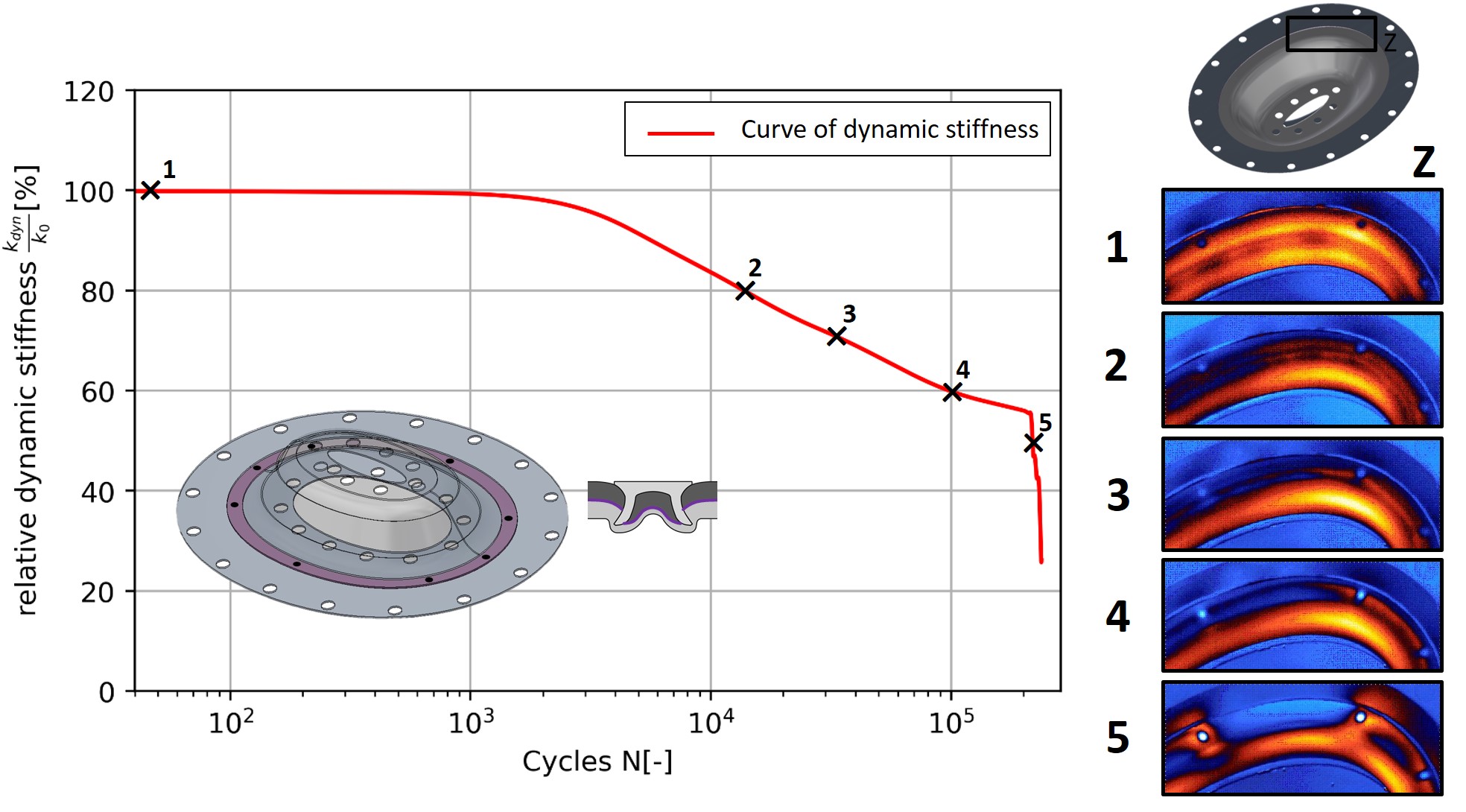

In order to determine the lightweight potential of structural components in multi-material design, the researchers carried out fatigue tests on bonded, riveted and hybrid joined bowl specimens. The bonded bowl specimens showed significantly higher fatigue load capacities compared to the riveted ones. Similar results were seen for the shear specimens. However, unlike the shear specimens, the hybrid joined bowl specimens exhibited lower fatigue load capacities compared to the bonded bowl specimens. "We suspect that one of the possible reasons for this behavior is that the hybrid manufacturing process has not yet been optimized, resulting in improper bonding of the components. This can also be seen in the comparison between the different batches of the hybrid joined bowl specimens," Baumgartner explains.

An additional fixing of the sheets during rivet setting proved to be a helpful approach. This reduced the amount of gap between the two sheets during the bonding process and thus increased the bonding quality and fatigue strength.

Dr. Boris Künkler, Manager CAE Methods, Expertise and Support (CMES) Opel/Vauxhall, Opel Automobile GmbH, Rüsselsheim, Germany, also emphasizes the promising results of the Alliance project: "One of the objectives of the ALLIANCE project was the development of an application-oriented simulation method for the reliable fatigue assessment of bonded and punch riveted sheet metal joints. The

results of the bowl specimen tests developed and conducted at Fraunhofer LBF were extremely helpful in validating the method under combined loading conditions."

Sponsors and partners

Six leading European carmakers (Daimler, Volkswagen, Fiat-Chrysler Research Centre, Volvo, Opel, and Toyota) have joined forces to form the ALLIANCE consortium (Affordable Lightweight Automobiles Alliance) together with four suppliers (Thyssenkrupp, Novelis, Batz, Benteler) and eight knowledge partners (Swerea, Inspire, Fraunhofer LBF, RWTH-IKA, KIT-IPEK, University of Florence, Bax & Company, and Ricardo). The ALLIANCE initiative is endorsed by EUCAR and EARPA. It is supported by European Union Horizon 2020.

Last modified: