Flame retardants, polyurethanes, TCPP alternatives

Sustainability flame retardant solutions: economic alternatives to TCPP for polyurethanes – search for project partners

Tris(chloroisopropyl) phosphate – TCPP for short – effectively protects mattresses, upholstered furniture, and even thermal insulation in buildings from flammability. However, it can be released during use and is suspected of being carcinogenic and harmful to reproduction. Fraunhofer LBF is looking for partners for the "SuFlaPUR" project. Together, they will research safe and cost-effective flame retardants for polyurethanes (PUR). The aim is to identify TCPP-free and economic alternatives that meet the strict flame retardancy requirements for flexible and rigid foams respectively. Suitable PUR formulations will be tested in close cooperation. The focus will be on the correlations between the chemical structure of the alternatives and their mode of action.

In the newly initiated "SuFlaPUR" project, researchers at the Fraunhofer Institute for Structural Durability and System Reliability LBF are working with industry partners to research cost-effective, high-performance alternatives to tris(chloroisopropyl) phosphate (TCPP). Alternatives currently available on the market are often cost-intensive, which makes substitution difficult, especially in cost-driven applications.

Cost-effective and safe alternatives for the polyurethane industry

As part of the project work, a comprehensive overview of flame retardants for PUR foams available on the market and known from the literature is being compiled. The participants define relevant applications and flame-retardant requirements. Based on this, model formulations are developed.

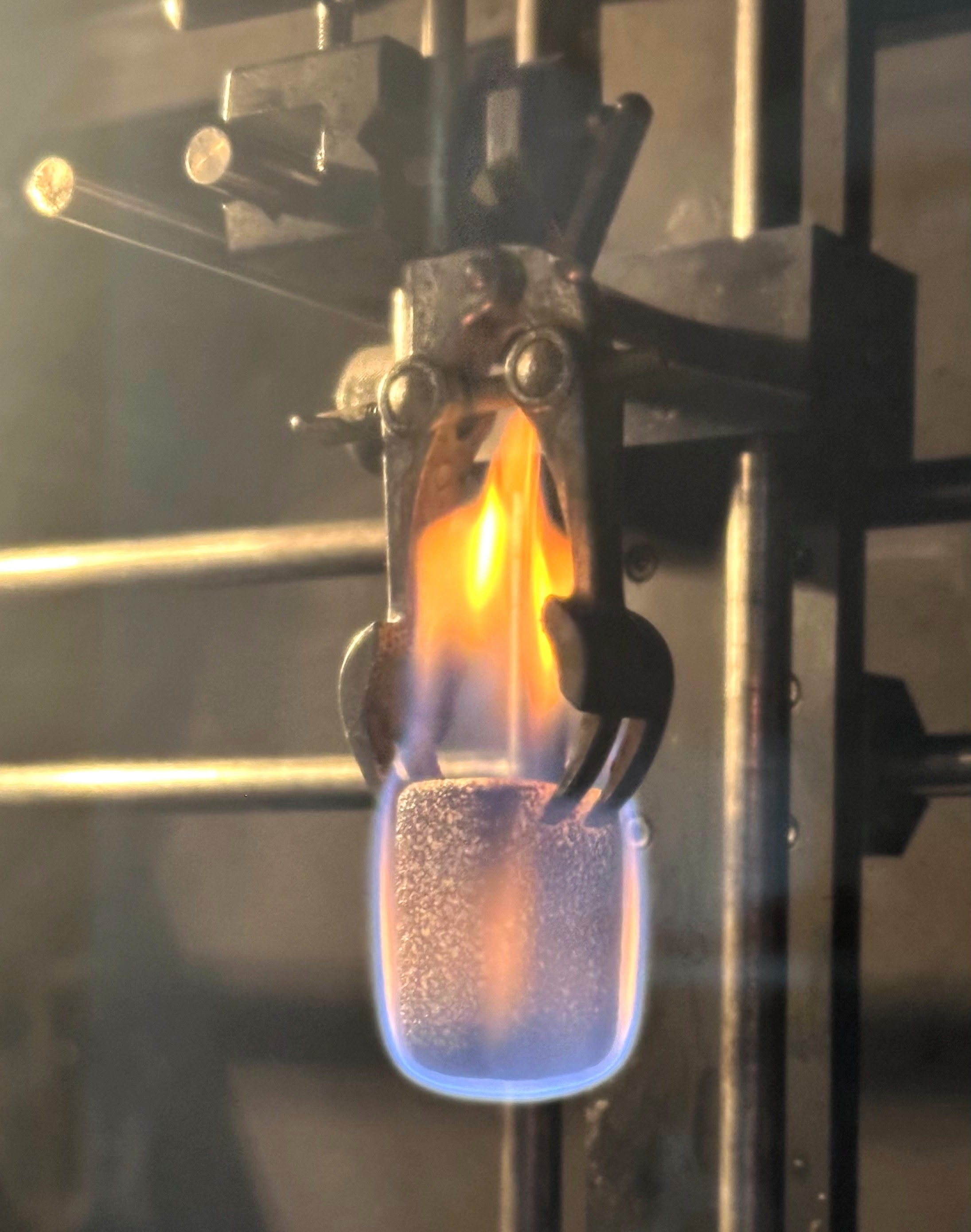

The experimental phase involves implementing the most promising formulations in PUR foams. Test specimens are produced to evaluate the flame-retardant properties. In addition, methods such as thermogravimetric analysis (TGA) and scanning electron microscopy are used to obtain information on how the flame retardants work. The influence of flame-retardant additives on mechanical properties such as the compression modulus is also investigated. The aim is to work with the project participants to develop practical recommendations for action to implement the alternatives found in industry.

Sustainable, environmentally friendly, and affordable

Manufacturers of flame retardants gain access to new formulations that offer safer alternatives to TCPP. Manufacturers of polyurethanes can optimize their products by using more environmentally friendly flame retardants, which strengthens their market position. System houses benefit from improved products and can offer their customers innovative solutions. End users who use mattresses, upholstered furniture, or thermal insulation benefit from safer products with lower health risks.

Last modified:

Fraunhofer Institute for Structural Durability and System Reliability LBF

Fraunhofer Institute for Structural Durability and System Reliability LBF