Plastic instead of metal: reducing costs and saving resources with thermoplastic components

Increasing restrictions on resource availability and the resulting rise in costs are prompting consideration of manufacturing components for a wide variety of applications from plastic instead of metal. Examples include load-bearing components in the engine compartment, baskets and housing components in industrial washing machines, housings and impellers, also for larger blowers in air conditioning and process engineering, and containers for lubricants. In the latter case, the use of transparent plastics also allows for visual level control. Due to their cost-effective mass production capabilities, thermoplastics are the primary materials being considered here.

The increased use of plastics also reduces energy consumption and thus greenhouse gas emissions along the entire value chain. Metallurgical processes are inherently associated with high energy consumption.

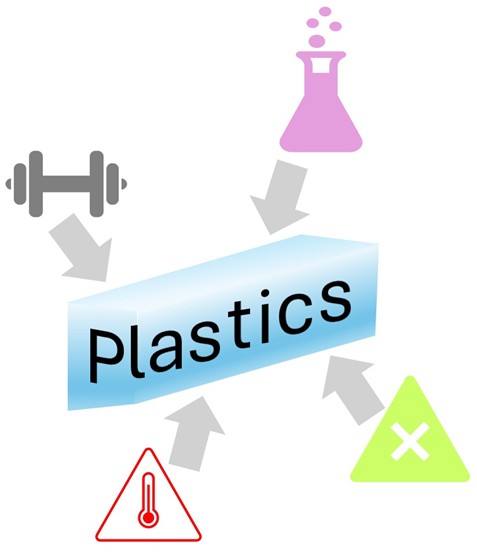

When switching from metals to plastics, one is often confronted with the challenge that the given operating conditions, such as high temperatures, mechanical stress, and the effects of media, seem to push plastics to their limits. In many cases, there is only little data on resistiveness in literature available.

This is where the proposed joint project comes in. The aim is to determine the range of applications for selected types of thermoplastics. This will enable the project partners to immediately assess the suitability of plastics for specific applications. The LBF has the equipment and practical experience to carry out the following tests:

All storage operations can also be carried out under static bending loads.

Identify application scenarios

The first step in the joint project is to work with the project partners to identify application scenarios for which the use of plastics is desired, such as:

Compiling plastic types and data

For two to three specific scenarios, a literature review will be conducted to compile the relevant types of plastic and their data. The initial focus will be on reinforced high-performance polyamides, as these are potentially suitable for a wide range of temperature and mechanical requirements. To complete the data or to determine the data that is particularly relevant for the selected scenarios, the corresponding storage tests will be carried out at the LBF.

Project partners who would have liked to have their own molding compounds characterized with confidential treatment of the results can still benefit from the joint project, as the provision costs are minimized due to the full utilization of, for example, the ovens.

All results approved by the project partners will be discussed with the group of participants and recorded in a final report.