Safety and sustainability in flame-retardant PUR formulations

Tris(chloroisopropyl)phosphate, or TCPP for short, is frequently utilized as a flame retardant in polyurethanes (PUR). Polyurethanes treated with this flame retardant are often used in flexible foams (e.g., for mattresses or upholstered furniture) or rigid foams (e.g., for thermal insulation in buildings).

The compound TCPP is suspected of being carcinogenic and harmful to reproduction.1 Nevertheless, its high chlorine and phosphorus content, along with its volatility, make TCPP an effective and cost-efficient flame retardant.2

While the volatility of TCPP is an advantage in the event of a fire, supporting its effectiveness in the gas phase, TCPP also migrates from the polyurethane foam during product use. This migration can result in TCPP being released into the environment (for instance, indoor air), which poses a toxicity concern.3 In addition to products based on aliphatic chlorophosphates, aliphatic phosphates, and phosphonates, there are also alternative products on the market. These include, for example, polymeric and reactive products (such as VeriQuel R100). The latter have the advantage that they are chemically bound in the matrix, which effectively suppresses migration. However, these products are more expensive, which makes substitution difficult, especially in cost-driven applications.

The goal of this joint project is therefore to identify PUR formulations that are optimized in terms of cost/performance, using selected applications as examples and based on commercially available and literature-known alternative flame retardants. This can be achieved, for example, by using synergistic mixtures.

In addition, the project will investigate correlations between the structure of the alternative used and its mode of action in the exemplary formulations, as well as the resulting flame retardant properties.

Project participants will thus be provided with a toolkit for selecting suitable formulations and basic information on the mode of action of flame retardants, which can be used for their own further development. The project is aimed at flame retardant manufacturers, polyurethane manufacturers, system houses, and users of flame-retardant polyurethane foams.

First, the main focus areas will be identified among the participants. The applications most relevant to the participants (e.g., based on flexible or rigid foams) will be defined, and the (flame retardant) requirements to be met will be specified and focused. On this basis, one or more model formulations are determined, which will be used to investigate flame retardant additives in the further course of the project.

Subsequently, the open and patent literature is searched and classified with regard to reported TCPP-free alternatives. In addition, project participants will be provided with a comprehensive market overview of flame retardants for PUR foams. Where available, reported correlations between the structure of flame retardants and their mode of action or mechanism in PUR foams will be compiled and summarized.

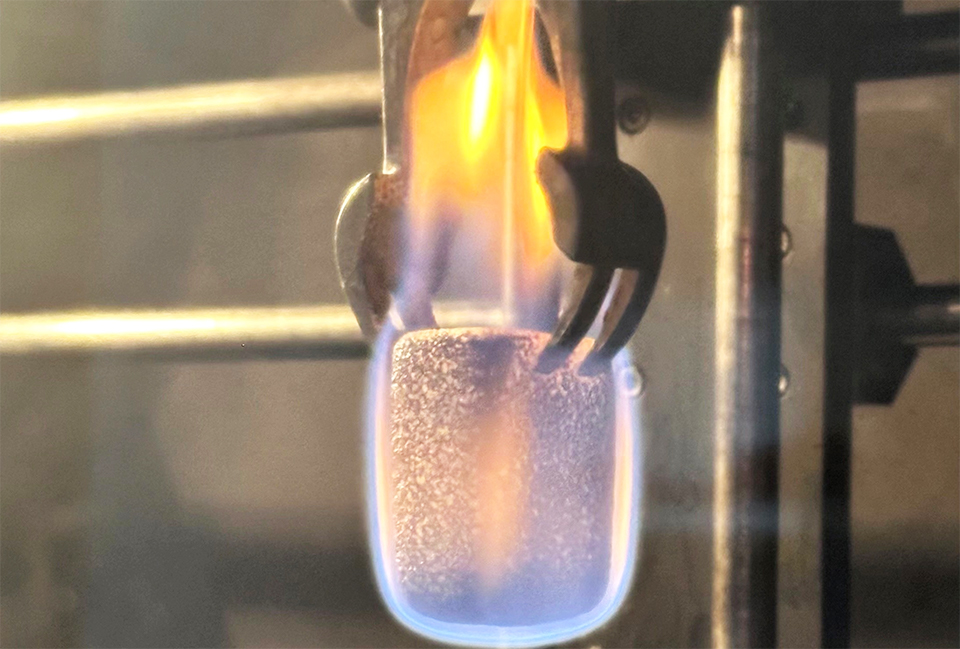

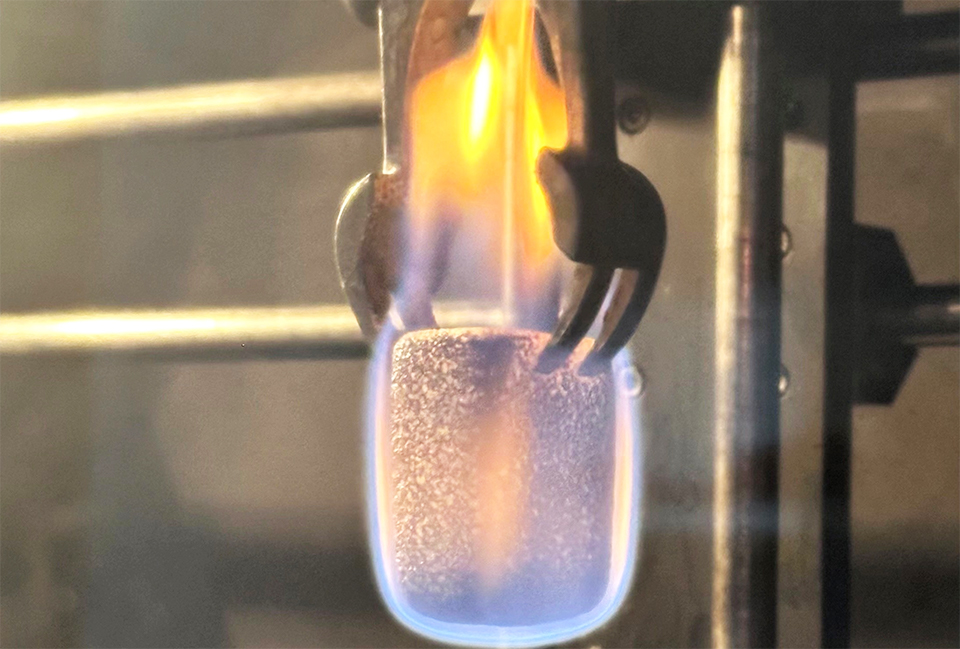

Promising approaches and formulations will be derived from this research and tested for flame retardancy in the following experimental project phase. To this end, the selected formulations will be implemented in PUR foams and test specimens will be produced on a laboratory scale to evaluate the flame retardant properties (e.g., UL-94, LOI if applicable).

To clarify the mode of action of the flame retardants, further investigations such as thermogravimetric analysis (TGA), microscopy (e.g., scanning electron microscopy), or cone calorimetry are used for selected formulations.

For promising formulations, the mechanical behavior (e.g., compression modulus) is also characterized in order to evaluate the influence of flame retardant additives on other application-relevant properties. The focus is on commercially available flame retardants and synergists to ensure that the participating companies can immediately implement the findings.

As part of the project, up to approximately 50 flame retardant combinations (divided into 4–5 iterative campaigns) will be tested at Fraunhofer LBF, including the characterization described above. Four to five campaigns will be carried out iteratively in consultation with the participants, and the findings from each campaign will be taken into account in the next campaign. Finally, participants will receive recommendations for action on possible substitutes, their components, their mode of action, and possible restrictions.

1 Krebsrisiko für Kinder durch Flammschutzmittel in Schaumstoffen, accessed on 2025/09/17

2 Journal of Fire Sciences 2025, Vol. 43(2) 115–124

3 Building and Environment 219 (2022) 109156