Scanning Acoustic Microscopy

With the help of scanning acoustic microscopy defects and small imperfections can be detected non-destructively. These are for example delaminations, inclusions, pores and cracks.

Furthermore hidden structures can be examined and the surface profile and layer thickness can be analyzed.

We support our customers in the adjustment of measurement procedures to the requirements of the audit engagement and the usage of high performance analysis algorithms.

Scanning acoustic microscopy can be used to examine different kinds of planar parts and test specimens, for example:

- Varnish and coatings

- Large planar structures such as photovoltaic modules and laminates

- Composite components, for example in lightweight construction

Tabbed contents

Scanning Acoustic Microscopy

With scanning acoustic microscopy a focused ultrasound wave is introduced into the sample over a coupling liquid. This way, measurements in reflection or transmission mode are possible. The transmitted or reflected signal contains depth dependent information. The acoustic contrast relies on differences in density or the mechanical moduli of neighboring structures (for example: delamination, inclusions, cracks). Furthermore, time of flight, acoustic attenuation and sound scattering deliver detailed information.

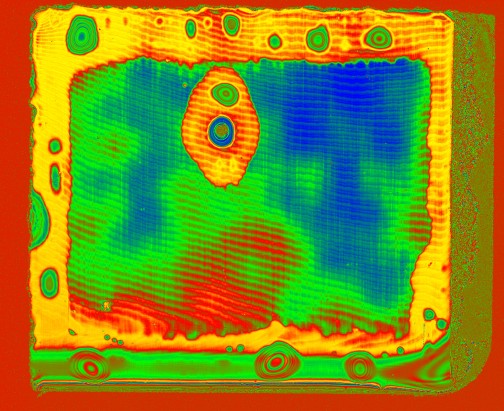

An area scan creates a data matrix, which can automatically interpret signal amplitude and time of flight into grey scale or color images. Scanning acoustic microscopy is suitable for imaging examinations of planar structures.

Instrument specifications "Evolution II":

- Lateral resolution: < 2 μm

- Vertical resolution: < 20 μm

- Scan area: 320 mm x 300 mm

- Maximum pixels: 8000 x 8000

- Testing frequency: 20 – 175 MHz

- Data acquisition speed: 1 GSamples/s

- Measurement modes: Pulse-Echo and Transmission

- Single piece und small series examination

Application Examples

With the help of scanning acoustic microscopy, defects that can lead to failure of the entire structure can be localized and analyzed.

Fraunhofer LBF is ideally equipped for non-destructive testing of coatings (upper and lower picture) and parts or composites based on polymers. Specific signal and image processing methods allow an early detection and evaluation of damages.

Scanning acoustic microscopy is complemented by other imaging techniques, such as infra-red and Raman microscopy, optical polarization microscopy and X-ray micro CT.

Publications

- H. Oehler, I. Alig, D. Lellinger, M. Bargmann

Progress in Organic Coatings 74 (2012) 719–725 - I. Alig, M. Bargmann, H. Oehler, D. Lellinger, M. Wanner, D. Koch

Phys. D: Appl. Phys. 44 (2011) 034009 (10pp) - H. Oehler, M. Bargmann, D. Lellinger, I. Alig

Farbe&Lack 117 (2011) 1, 34-37 - H. Oehler, M. Bargmann, D. Lellinger, I. Alig

Farbe&Lack 117 (2011) 4, 128-132 - I. Alig, S. Tadjbach, P. Krüger, H. Oehler, D. Lellinger

Progress in Organic Coatings 64 (2009) 112–119

Fraunhofer Institute for Structural Durability and System Reliability LBF

Fraunhofer Institute for Structural Durability and System Reliability LBF