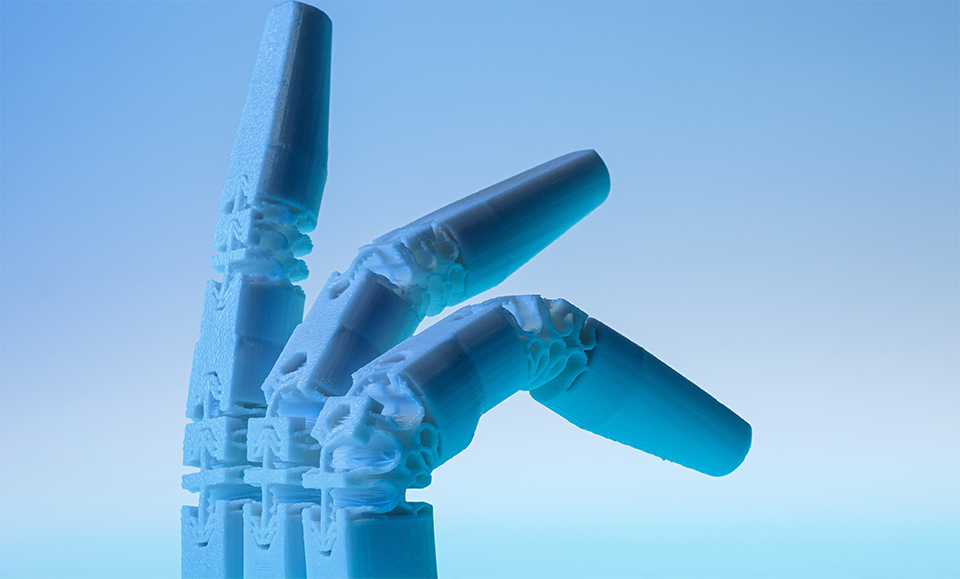

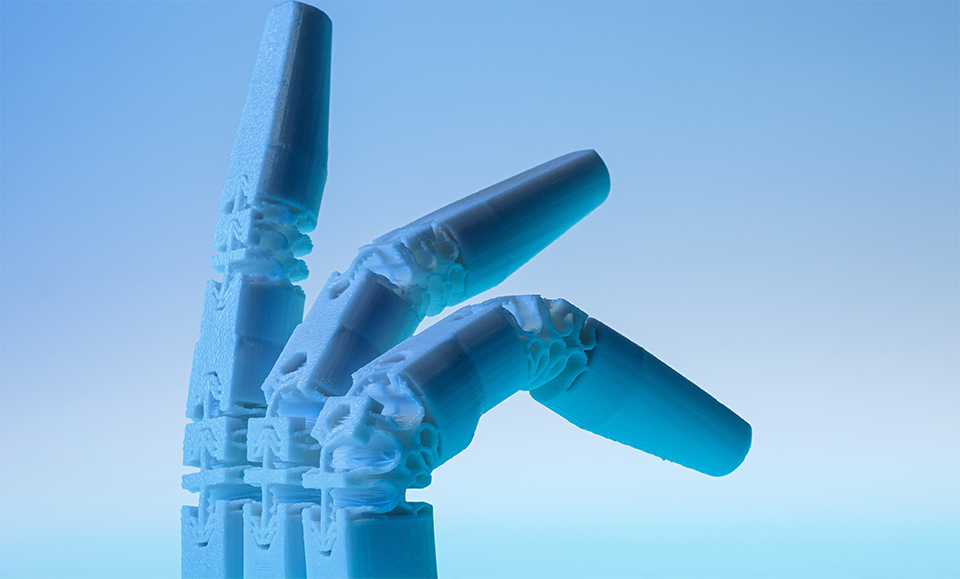

Replacement of a multi-part finger of a hand prosthesis with a single bistable programmable metamaterial.

Passive hand prostheses with articulated fingers are often attractive to end users due to their low cost. The Fraunhofer Cluster of Excellence Programmable Materials (CPM) is developing a finger for a hand prosthesis that can assume four stable deformation states. The Fraunhofer LBF, IWM, ITWM, and IAP are collaborating on the “ProFi” project to replace the previous multi-part, screw-fastened solution with a single programmable metamaterial in order to reduce assembly costs. This has been achieved with a joint structure that has only one degree of rotational freedom and a small bending radius and is interconnected with bistable unit cells.

The finger of the hand prosthesis should have two joints that only allow flexion around one axis and are as rigid as possible in the other degrees of freedom. At least three finger positions (extended: 0°, basic position: 30°, bent: 90°) should be fixable, which are passively adjusted by the second hand. Since the hand prosthesis primarily serves an aesthetic purpose, no further functionalities are required in the finger positions. The metamaterial should be scalable and its outer contour adaptable in order to reproduce as many individual fingers as possible in detail.

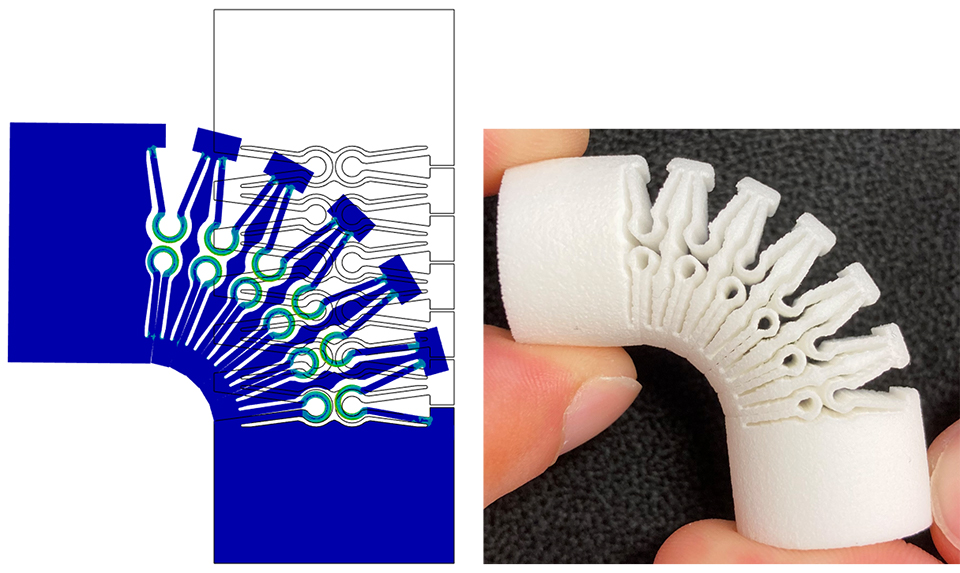

The concept of the joint structure is based on a metamaterial developed by Shaw et al. [1], which serves as a joint replacement for an elbow. Its special feature is its freely adjustable outer contour and a single degree of rotational freedom. Adjustments were made to the structure in order to transfer it to the significantly smaller installation space and to achieve a small bending radius. A parameter study is carried out using FEM simulation to reduce the stresses in the notches of the structure. The resulting joint structure allows a 90° bend in the specified installation space, has low stiffness in the bending direction, and can take on almost any outer contour.

The design of the bistable unit cell is based on a geometry used by Berwind et al. [2] for metastable mechanical shape memory structures. The principle is based on two elastic beams that are rigidly connected at the sides and break through under an orthogonal tensile load, thus having two stable states. A parameter study was also carried out for such a unit cell. Due to the large number of geometric parameters, the “ProgMatCode” software developed at CPM [3] was used. Bistability was evaluated by considering the tensile force, which runs from positive to negative. In order to increase bistability and prevent rotation out of the plane, the elastic beams were designed as parallel double beams in a further optimization.

To ensure optimum interaction between the two sub-functions, further adjustments were made when integrating the bistable unit cells into the joint structure. This improved the bistability, but reduced the bending stiffness perpendicular to the bending of the finger. The resulting bistable programmable joint was integrated in duplicate in different sizes into a simplified version of a finger. This can be bent by 90° at both joints, resulting in four stable positions in 30° increments. The finger can be manufactured additively from a single component without any assembly work.

[1] Shw et al., Nature Communications, Computationally efficient design of directionally complaint metamaterials, 2019

[2] Berwind et al., Advanced Engineering Materials, A Hierarchical Programmable Mechanical Metamaterial Unit Cell Showing Metastable Shape Memory, 2018

[3] T. Lichti, Development of Methods and Tools for the Design of Programmable Materials, TU Darmstadt, Diss., 2023