Applications for polymers

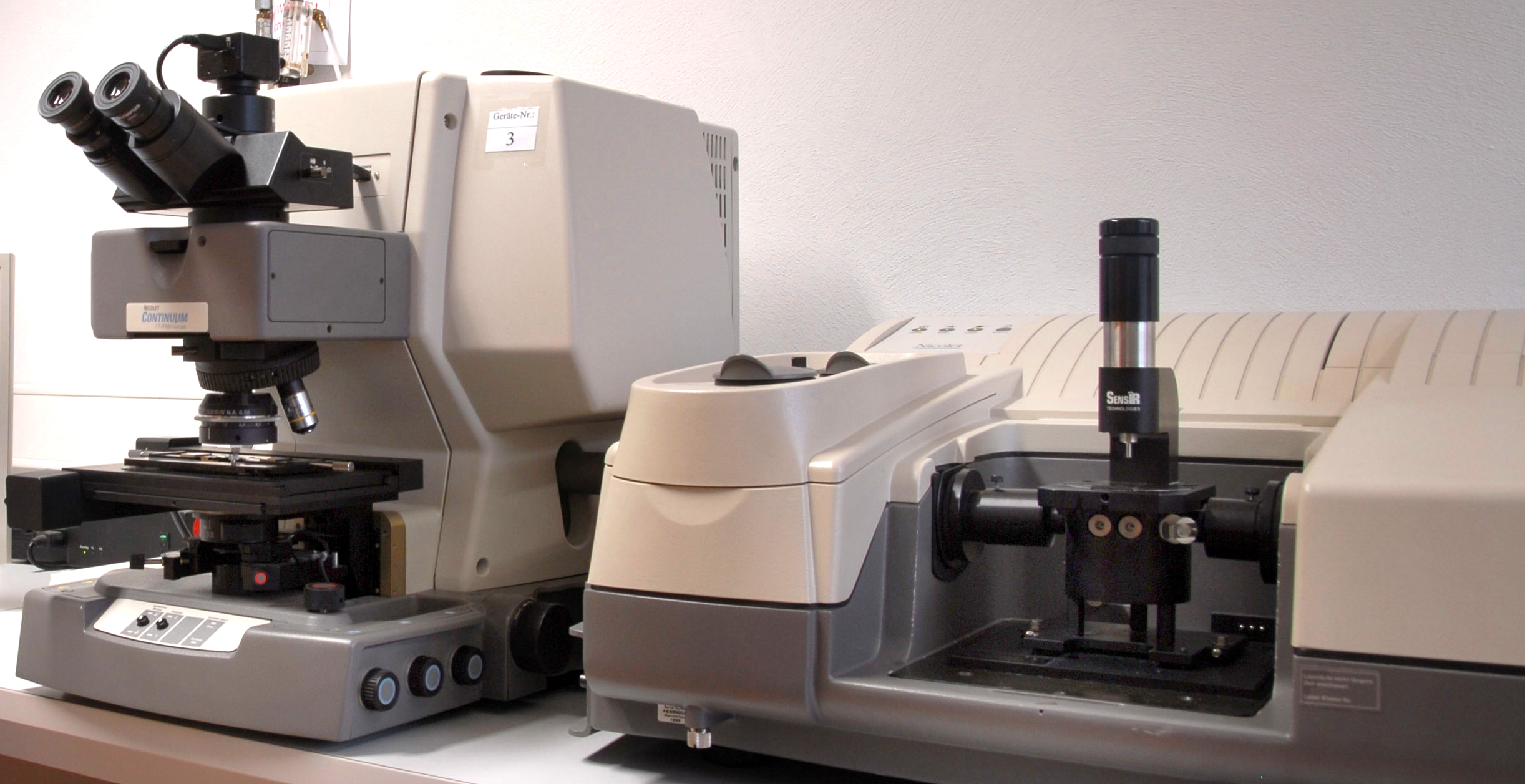

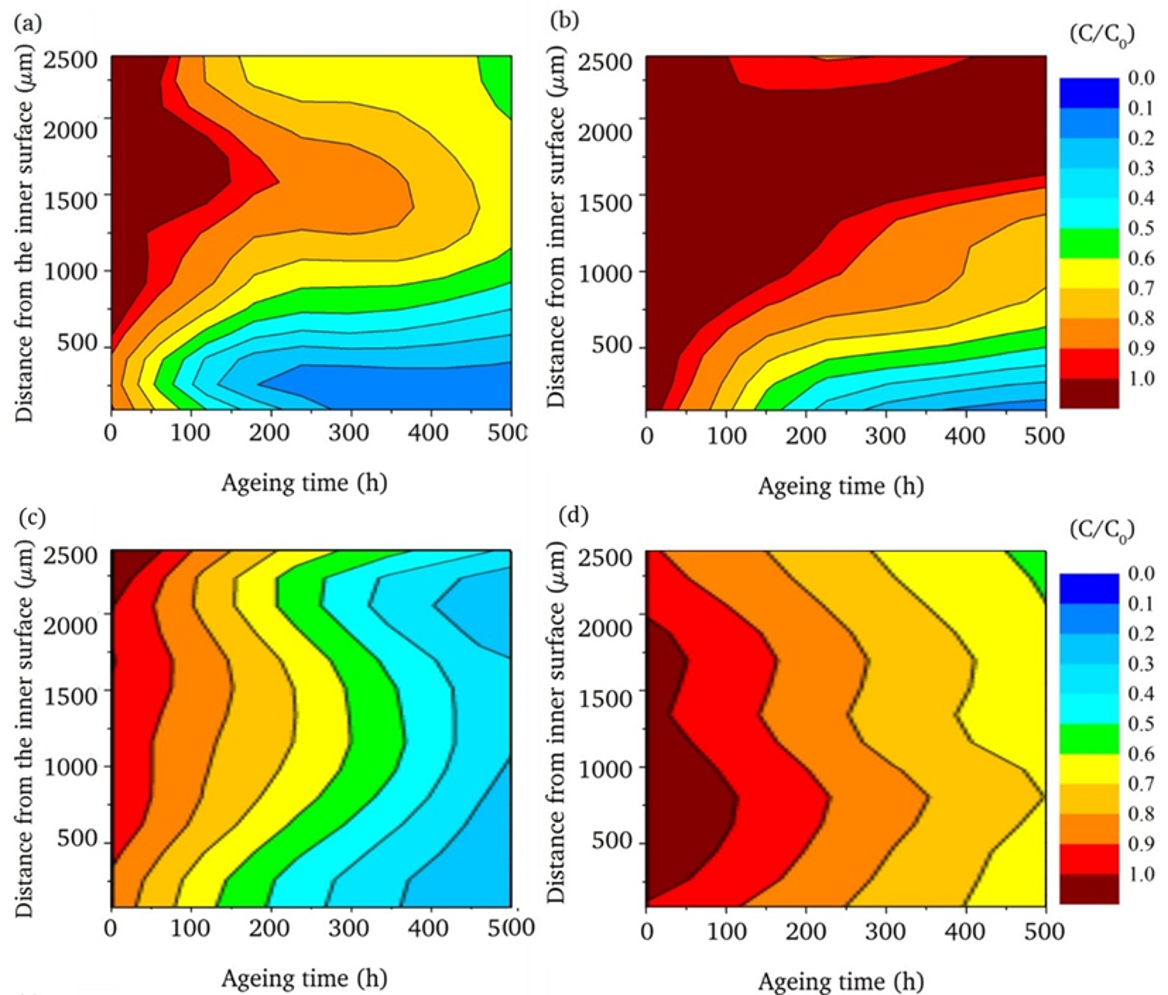

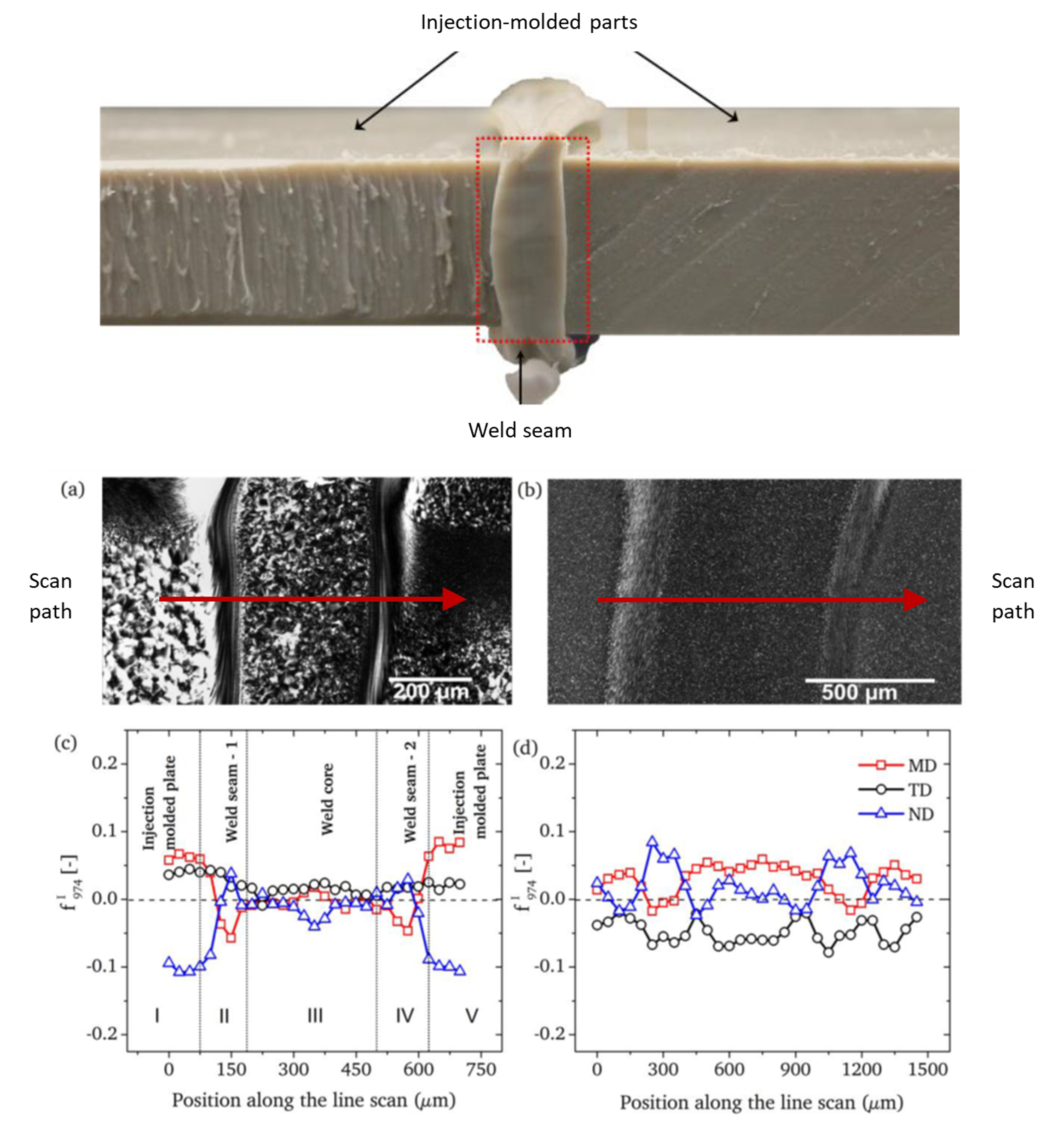

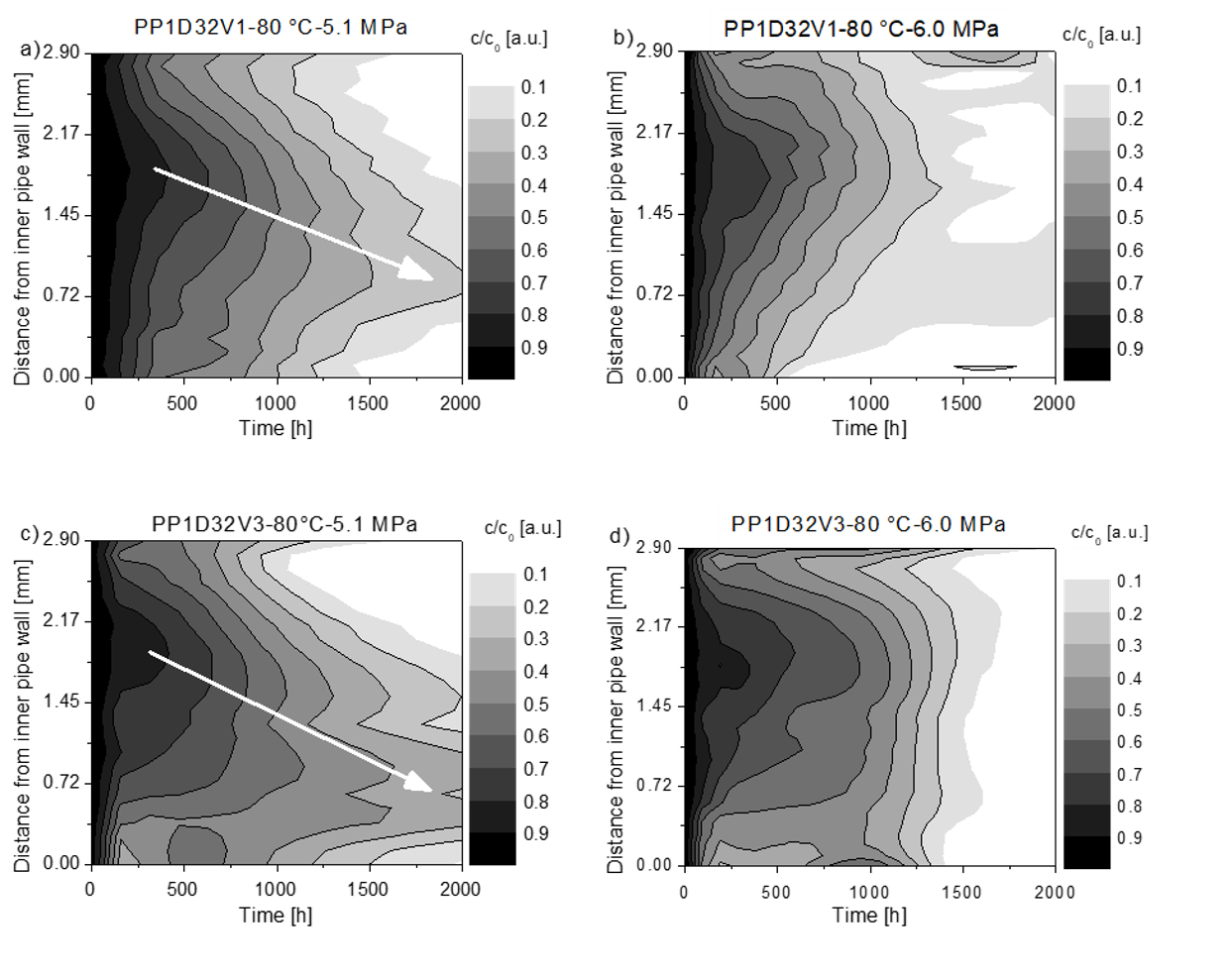

FTIR microscopy (µFTIR) combines infrared spectroscopy with a microscopic setup to investigate the chemical composition of polymers with spatial resolution. µFTIR provides detailed chemical imaging of small sample areas, identifying the distribution of specific chemical bonds and functional groups throughout the sample. It is a powerful technique to determine different phases or domains within a polymer matrix (polymer blends, copolymers, additives, impurities, degradation products, composites, multilayer films). Therefore, µFTIR has great potential to answer current questions for R&D and Q&S of plastics and plastic products.