If a vehicle has less weight, less propulsion power is required to achieve comparable driving performance. This means that less pollutants are emitted, which makes lightweight construction a key technology in the automotive sector. In addition, lightweight structures are the only answer to the high weight of the battery in hybrid and electric cars.

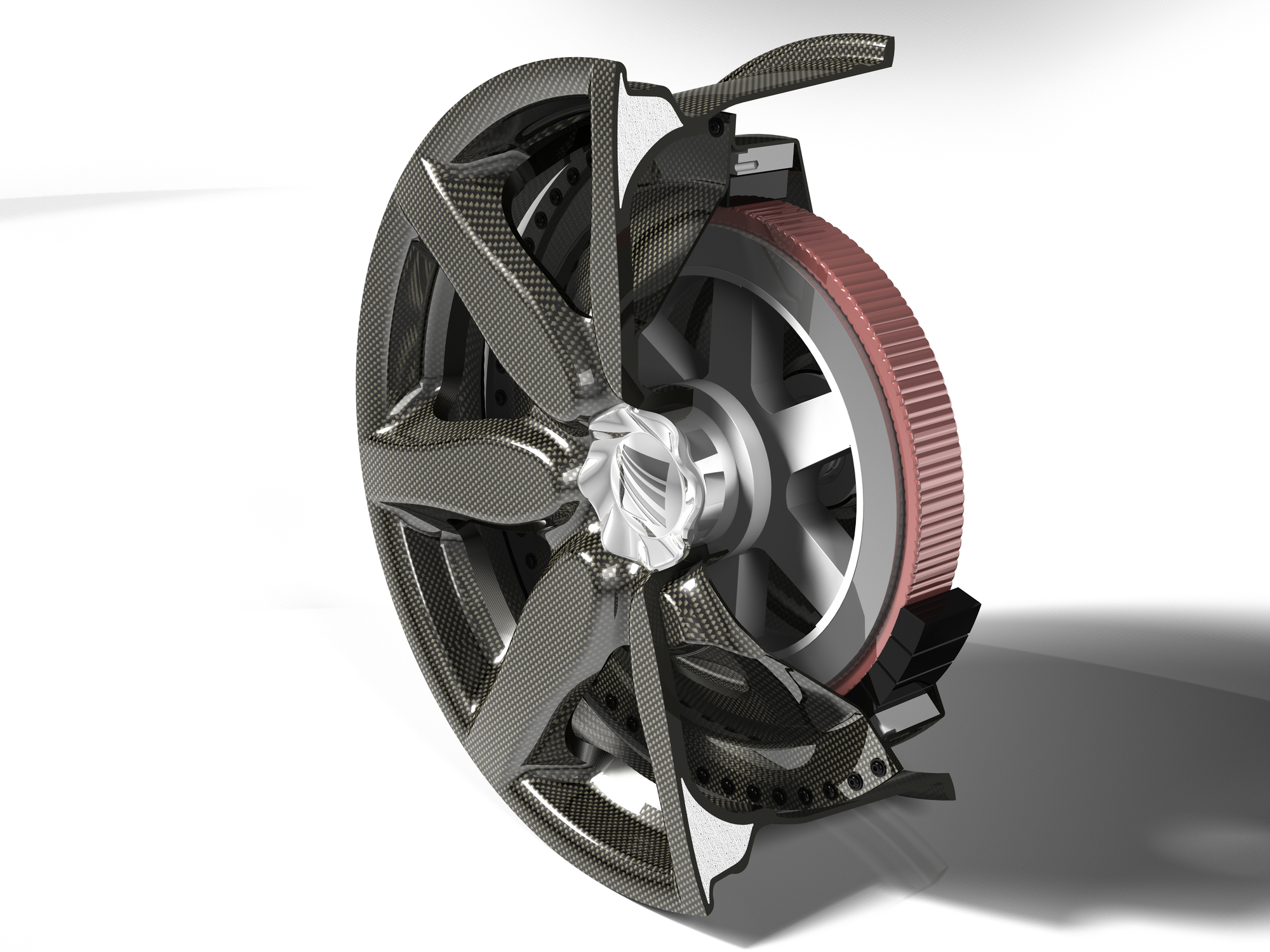

Composite fiber wheel with integrated electric motor

Composite fiber wheel with integrated electric motor

In electric vehicles, the conventional internal-combustion engine is replaced with one or several electric motors. To highlight the opportunities this alternative drive system offers, a fiber composite lightweight wheel was developed at Fraunhofer LBF within the framework of a collaborative research project in the field of electromobility.

The CFRP wheel with a wheel size of 6.5 x 15“ has a weight of about 3.5 kg. In comparison to a steel wheel of the same size, this means a reduction of up to 60% in weight, depending on the wheel design. Compared to an aluminium-cast wheel, the weight reduction amounts to up to 56% depending on the design.

The motor adapter flange is not directly connected with the rim base. This prevents radial or lateral loads from being transferred directly onto the electric motor. To align the fibers continuously and with the flow of the forces and to avoid stress peaks caused by sharp edges or sudden variations in rigidity, radii that are in line with the material and smooth transitions have been created in the component. The motor adapter flange is connected with the interior area of the wheel axle. To reduce the mass and increase flexural strength, foam cores have been integrated into the spokes. The electric motor is a small, commercially available wheel hub motor. The motor, consisting of a permanent magnet (outer rotor) and a yoke ring with solenoids (stator) has a power of 4kW and a control voltage of 2 x 24.5 V.

Lower weight - higher structural stability

If appropriately designed, the use of fiber-reinforced plastics (FRP) enables higher stiffness, enhanced material damping properties and higher damage tolerance - with lower weights at that - to be obtained. E. g., in the area where the electric motor and the fiber composite wheel (motor adaptor flange) are connected, a higher natural frequency can be achieved, with enhanced damping properties, thanks to the use of high-modulus fibers, which, in addition to the great lightweight potential, enables low noise emission to be achieved. A further advantage of the composite fiber construction, in addition to the high freedom in design, is the option of integrating function. As compared with lightweight metal materials, fiber-reinforced plastics also offer some more degrees of freedom, by means of which the material and component characteristics may be influenced. The type of the matrix and of the fibers has an influence on the characteristics, as well as their proportion to each other and the orientation of the fibers within the component. Weight, structural durability and the costs and complexities of the manufacturing process may be tailored to the requirements of the individual application.

More information about Smart Structures:

The fiber composite wheel has won a price in the 2012 competition "365 locations in the country of ideas".

Fraunhofer Institute for Structural Durability and System Reliability LBF

Fraunhofer Institute for Structural Durability and System Reliability LBF