Like other materials, polymers undergo aging processes. For this reason, the prediction of the service life of plastics in outdoor applications is of particular significance. Anti-corrosion coatings, resin-based composites for wind power stations, and, not least, components for use in cars, railways or aircraft demand high long-term stability. Given that long testing cycles result in high cost and extended development cycles, industry has always been looking to reduce testing times. One way of accelerating the testing procedure is through simulated weathering in the laboratory. However, in many cases, reproducing the results of outdoor weathering in the laboratory has proven to be difficult. New customized weathering cycles and validated methods of early damage detection are expected to remedy this situation.

Better prediction of the lifetime of polymer materials

Monitoring of aging effects and damage

The aging of polymers is characterized by the interaction of numerous physical and chemical processes: Molecular processes are accelerated by high temperatures. Water or organic media may penetrate into the polymer and change the material structure. Additives are expelled, and chemical processes lead to material embrittlement or fragmentation of the molecules. To predict the service life of a component, you need to analyze and understand these processes and develop appropriate models.

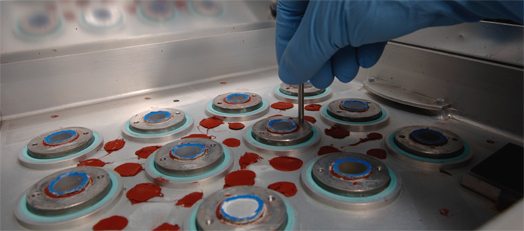

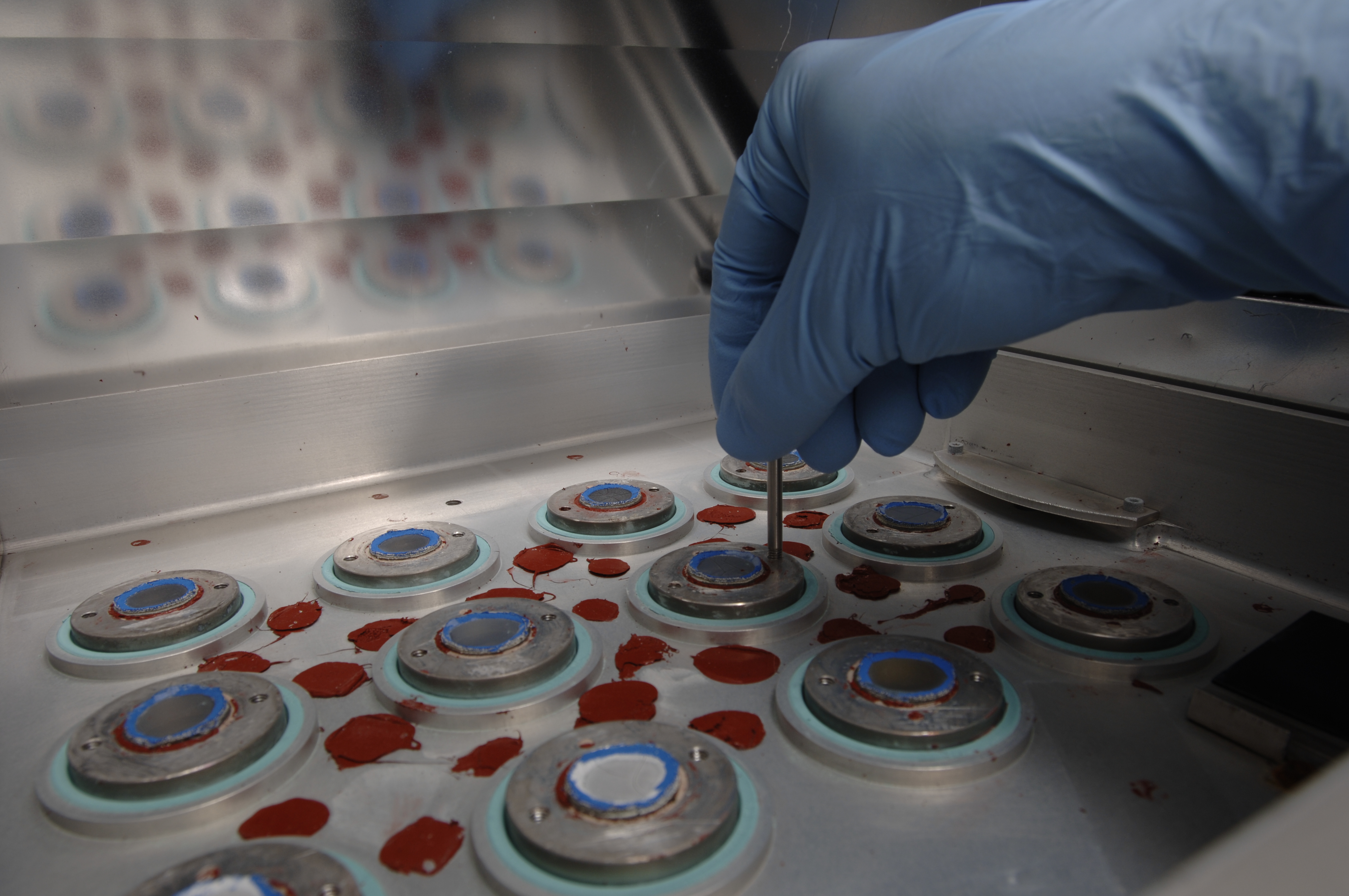

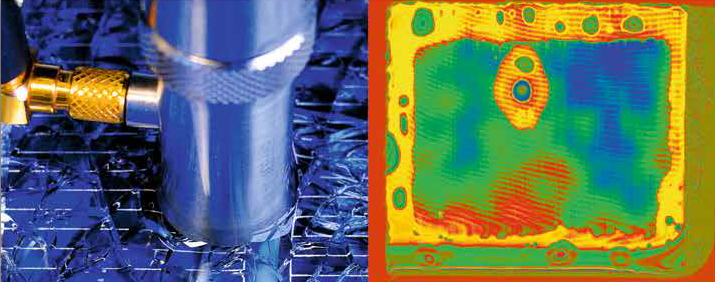

This necessitates complex long-term tests under realistic ambient conditions. At the same time the occurrence and propagation of damage has to be recorded by spatially and time resolved measurements. The Plastics Division at Fraunhofer LBF can provide suitable measuring and testing equipment along with the necessary expertise for characterizing ageing processes in plastics. For example, technologies such as ultrasound measurement and spatially resolved nuclear magnetic resonance spectroscopy have been incorporated into simulated weathering devices. Tracking changes in a material in-situ enables the weathering cycles to be optimized. Non-destructive testing of weathered polymer coatings for automotive applications or aeronautics is conducted, for example, by means of advanced ultrasound microscopy. Signal and image processing methods enable the early detection and quantitative assessment of damage. Conventional structural investigation with imaging and scattering methods, dynamic-mechanical analysis or differential calorimetry complement these highly specialized methods. In addition, methods for molar mass determination and optical spectroscopy are used to determine chemical changes.

New laboratory for studying humidity and solvent effects

Even small quantities of water or organic substances may act as a "softener" in the plastic and cause permanent damage to the material structure. To measure moisture absorption and sorption of organic substances, two measuring systems were set up with financial support from the State of Hessen. Now sorption and diffusion measurements can be conducted at different humidities and temperatures and in organic liquids. In addition a new measuring system for dynamic-mechanical analysis at defined humidity and in solvents has been installed.

Fraunhofer Institute for Structural Durability and System Reliability LBF

Fraunhofer Institute for Structural Durability and System Reliability LBF