Metal cushions, vibration mitigation, vibration absorber, vibration reduction

The special mechanical properties of metal cushions stem from their complex inner structure and how the wire segments interact with each other. The friction produced by the wire gives it a good damping effect, which makes it predestined for applications in vibration technology. While the quasistatic behavior of metal cushions has been subject to scientific investigation many times, there is still little known about their dynamic behavior in the kilohertz range, even though this range is of particular interest due to the continuing electrification of transport. With its wide-ranging measurement technology equipment and many years of experience in the experimental and numerical investigation of systems, the scientists of Fraunhofer LBF aim to fill this gap and demonstrate new potential applications for metal cushions in vibration technology.

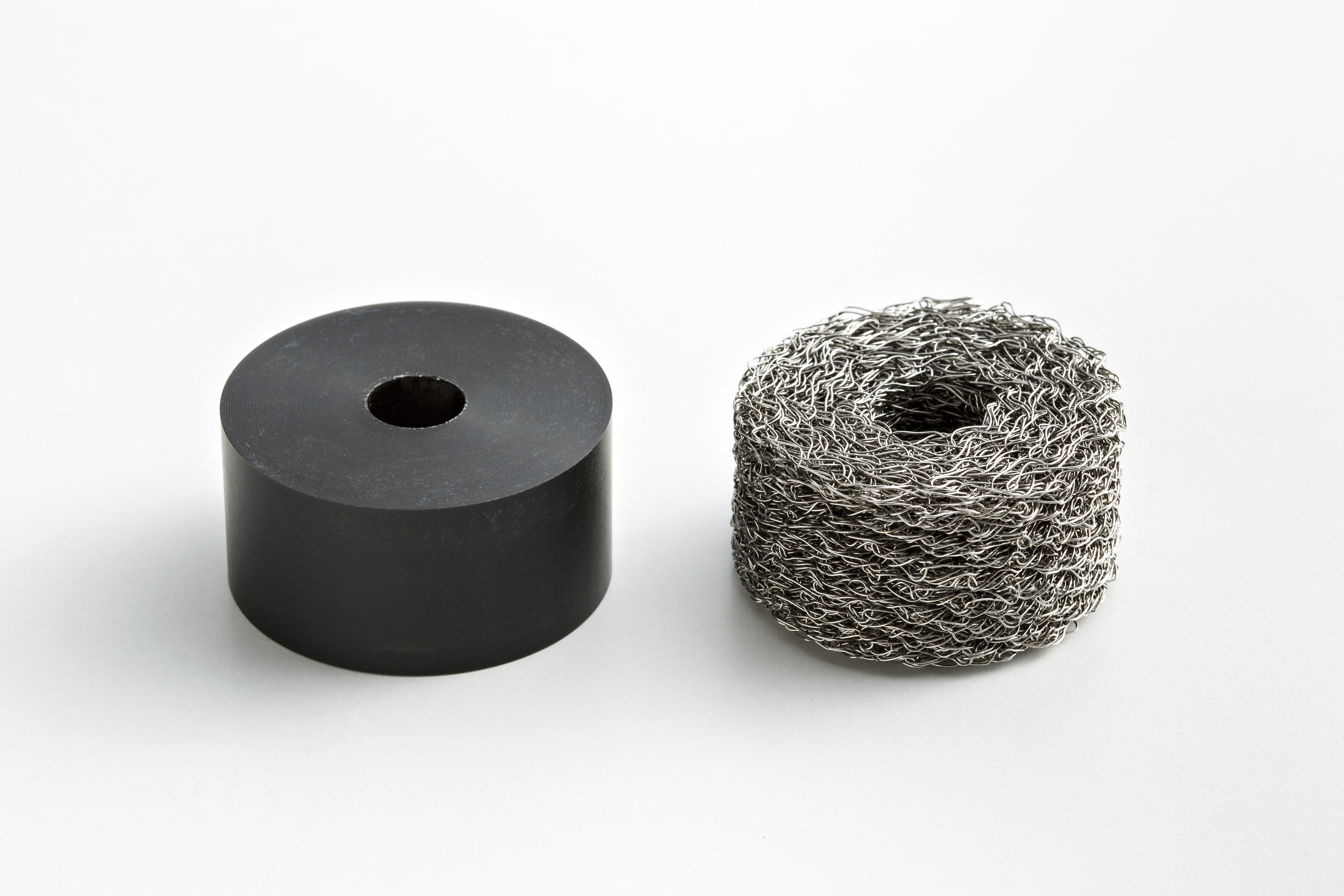

A distinctive feature of metal cushions is their high degree of compressibility. They can be reversibly deformed by well over 40%, which causes significant changes to their mechanical properties due to the increase in the inner connections of the woven wire mesh. These dependencies can be used specifically for applications in which dynamic properties should be varied.

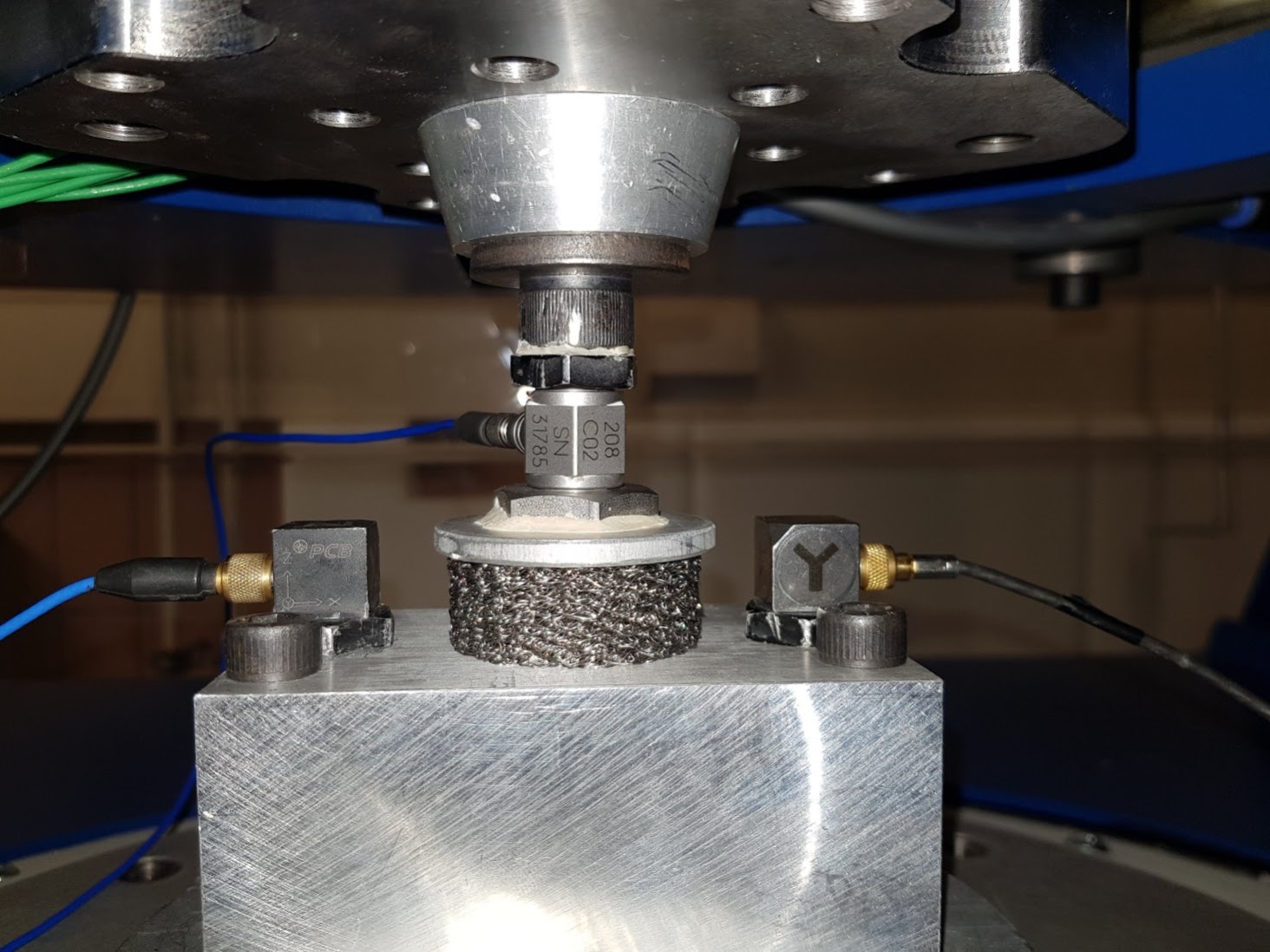

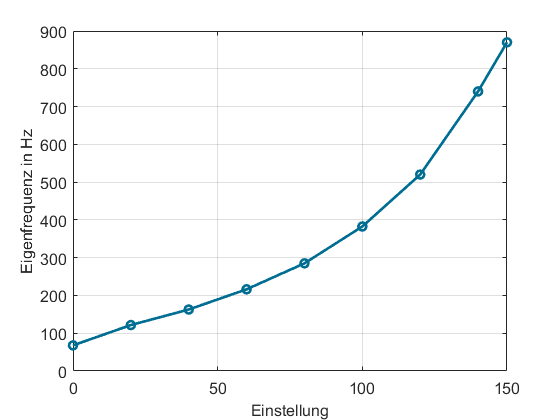

Fraunhofer LBF has developed an adaptive vibration absorber based on metal cushions. Here, a vibrating mass is mounted between two metal cushions, whose pre-stressing affects their rigidity, thereby influencing the resonance frequency of the absorber.

In this way, simple mechanics can be used to manually tune the resonant frequency of the absorber in small increments. In the prototype implemented, the resonant frequency can be tuned between 70 and 870 Hz in 150 intervals by turning the lid of the housing. The damping of the absorber can be varied in the range of between 0.2 and 20%.

These manually tunable vibration absorbers are suitable as development tools in test environments for the rapid potential analysis of damping solutions for mitigating vibrations and the experimental identification of the optimal damper parameters. If required, an actuator can also be included so that the parameter identification can be performed automatically.

With the damper concept based on metal cushions, Fraunhofer LBF is expanding its portfolio of passive, adaptive and active solutions for vibration mitigation and is able to offer its customers solutions that are both highly flexible, as well as being tailored to individual issues. This can include, for instance, absorbers, neutralizers and dampers, as well as elastic bearings based on metal cushions.