Tests with little stabilized virgin material

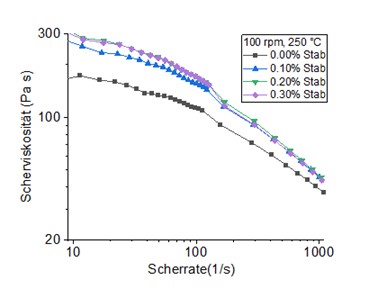

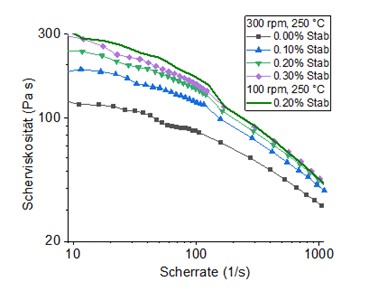

The flow curves with varying amounts of a typical commercial process stabilizer (“Stab”) are shown for screw speeds of a) 100 rpm and b) 300 rpm in Fig. 3.

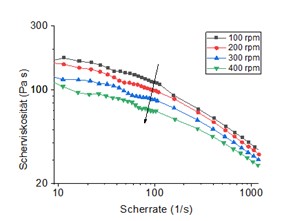

Without additives, the curves are essentially the same as those in Fig. 2 for the corresponding screw speeds.

In Fig. 3a), at 100 rpm, a significant shift of the flow curve towards higher viscosity values can be seen when feeding 0.1% of the stabilizer. Doubling this amount results in a further slight increase of the viscosity values, while the curve for 0.3% is virtually the same as for 0.2%.

When applying 300 rpm (Fig. 3b) the flow curves also shift towards higher viscosities with increasing additive content. However, the viscosity values while feeding 0.3 % stabilizer are below those which are recorded at 100 rpm and only 0.2% of the additive.

This allows us to conclude: At processing with 100 rpm screw speed, the process-induced degradation can be virtually suppressed by 0.2 % additive and raising the amount (here: 0.3%) does not have any effect.

At 300 rpm on the other hand, degradation becomes more prominent and cannot be completely suppressed with even 0.3% of stabilizer.

Potential for batch-adapted post-stabilization in real time

This example demonstrates that online rheology provides valuable information regarding the efficacy of a processing stabilizer already during compounding. It can be expected that this approach will help to accelerate the development of new formulations, in particular in the context of the circular plastics economy.

Furthermore, the flow curves of the different polymers are not identical. The information content of a flow curve is therefore much higher than that of a single numerical value from an MVR measurement. In addition, the flow curves of the elongational viscosity can be included in the evaluation. Supported by an appropriate AI based system, online rheology appears to be a very promising tool to implement stabilizing during the production of recyclates with the ability of real-time adjustment to the aging stage of the mill charges.