circular economy, biobased plastics, chromatography

Polylactide or polylactic acid (PLA) is the most important biobased thermoplastic derived from renewable raw materials. PLA is compounded with other bio-based and/or biodegradable polymers to increase its range of applications. A key challenge for the targeted development of these materials is linking the material heterogeneities of these blends with the application properties, i.e. working out the relationships between structure and properties. This has given rise to a great need to develop analytical methods to identify the chemical heterogeneities of blends made from biobased plastics. For this purpose, Fraunhofer LBF, together with Fraunhofer IAP, has developed high-performance analytics to determine the molar-mass-dependent chemical composition and microstructure of PLA/PBSA blends.

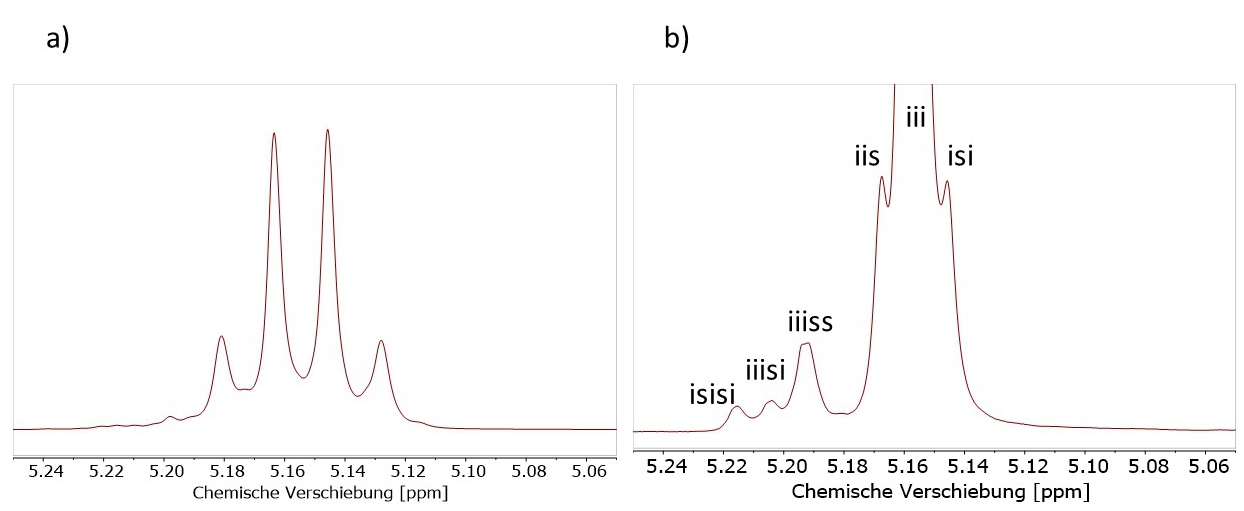

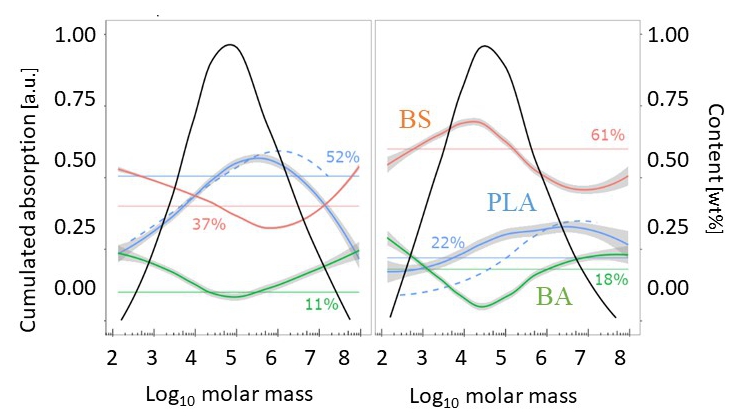

The sustainable establishment of biobased plastics and their ability to successfully compete with petroleum-based thermoplastics is dependent on the development of materials with more distinct properties and optimized material properties. This requires an in-depth understanding of the relationship between structure and properties, based on knowledge of the chemical heterogeneities. The latter can only be achieved by coupling chromatographic separation with spectroscopic detection. The offline coupling of gel permeation chromatography (GPC) with 13C nuclear magnetic resonance (NMR) spectrography used by Fraunhofer LBF has delivered conclusions regarding the molar-mass-dependent distribution of the chemical composition and microstructure of PLA and PBSA that were not previously possible. In this way, it was possible to determine a variance in chemical composition of between 25 wt% and 60 wt% along the molar mass distribution for any given overall (50/50) composition. In addition, it was possible to demonstrate that both the tacticity of PLA and the regioregularity of PBSA are functions of the molar mass.

Established analytical methods are set apart by their speed and cost-effectiveness. To meet this demand/need for the analysis of PLA/PBSA blends, Fraunhofer LBF has developed an online GPC-IPR with multivariate data evaluation. One process step involves separating the polymer mixture chromatically and the continuous spectrographic analysis of the chemical composition. The use of multivariate methods makes it possible to individually determine the proportion of adipates and succinates for the first time. This has resulted in entirely new perspectives regarding the investigation of biobased and biodegradable plastics and their blends.

The analytical techniques developed as part of this project can also be used for other biobased thermoplastics and their compounds. Likewise, they can be used for material development as well as the optimization of manufacturing processes. Furthermore, the methods used at Fraunhofer LBF are capable of withstanding high temperatures, meaning that they can also be used for high-performance thermoplastics. This creates great potential for developers and processors of biobased plastics, allowing them to make use of these results for their material and process development.