Using recycled plastic in highly stressed components

The use of recylates in technical applications offers huge potential for CO2 savings. Currently, there tends to be a reticence to use recyclates in technically demanding applications because the necessary characteristic values for the service life are generally not known. Working together in partnership, Bosch, BSH and Fraunhofer LBF carried out extensive investigations into the morphological and mechanical properties of a polypropylene recyclate and compared the results with the brand-new material that is currently in use.

The recyclate originated from used starter battery housings, and was compounded and optimized — from a usage requirements perspective — by Bosch and BSB (a recycling company located in Braubach). This involved comminuting, cleaning and drying the polypropylene housings. In a subsequent compounding process, the molten material was filtered; mixed with additives, stabilizers and fillers (in this case: 30% talcum by weight); and then granulated.

To gain a better understanding of the differences between the properties of recyclate and brand-new material, extensive analytical and mechanical investigations were carried out on material samples. From an analytical perspective, the molar mass distribution, the degree of crystallinity and the level of contamination by metals or foreign polymers were investigated, for example. Meanwhile, mechanical investigations were used to examine how the service life was affected by the interplay of static and cyclic loading on notches and the joint line, as well as the temperature, load ratio and aging. To ensure that the recyclate and brand-new material were comprehensively characterized for the planned intended use, 250 static tensile tests and 450 fatigue strength tests were carried out.

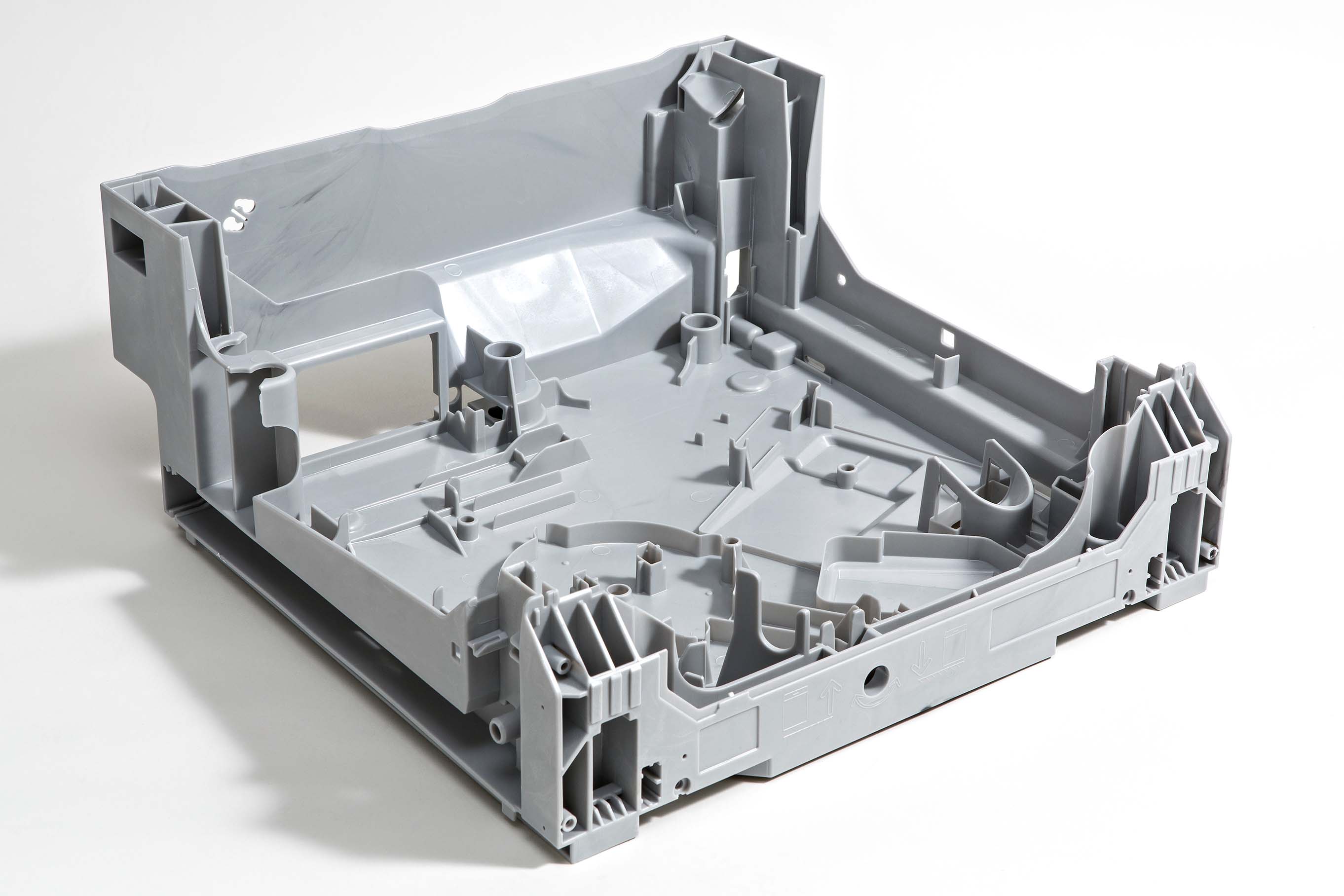

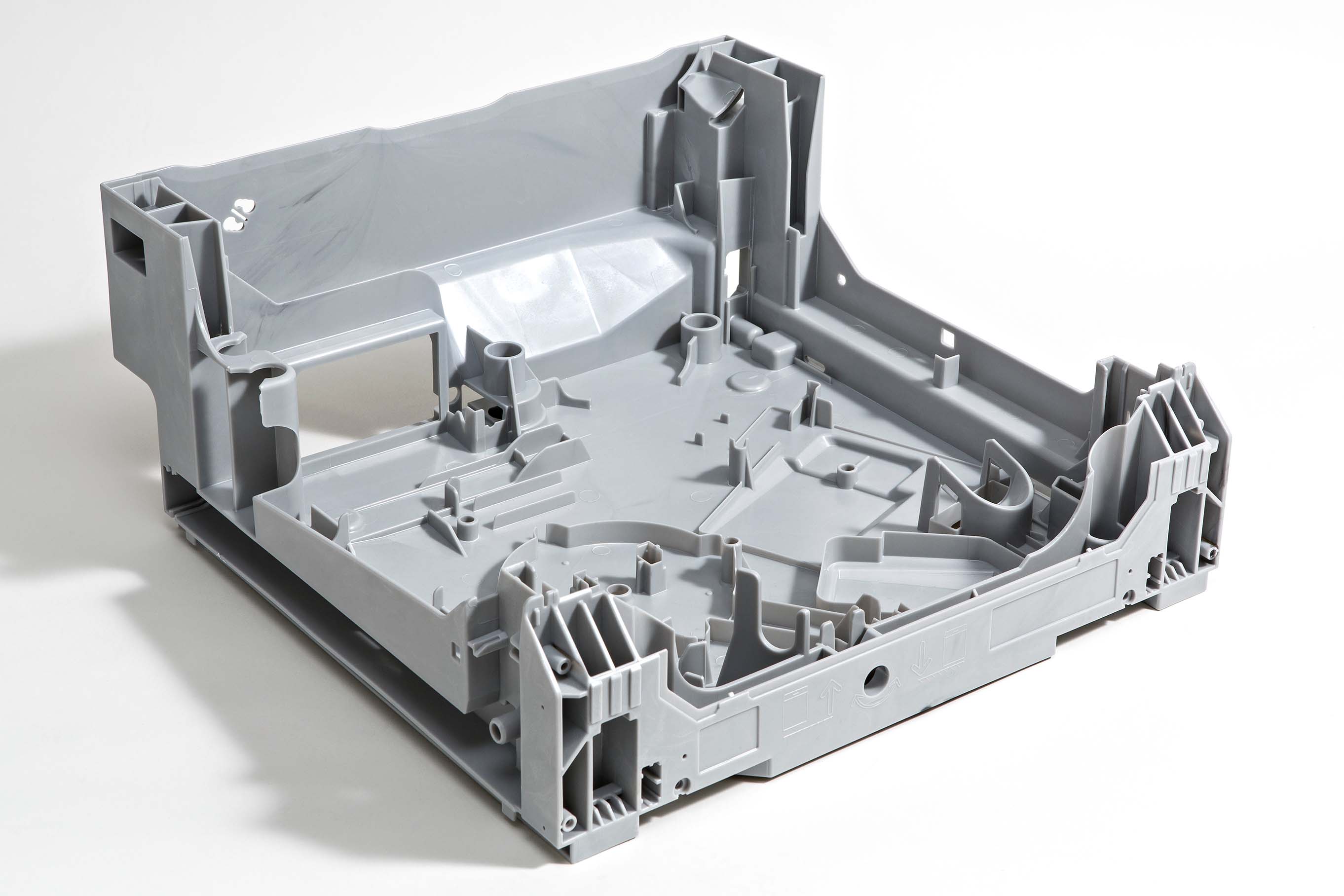

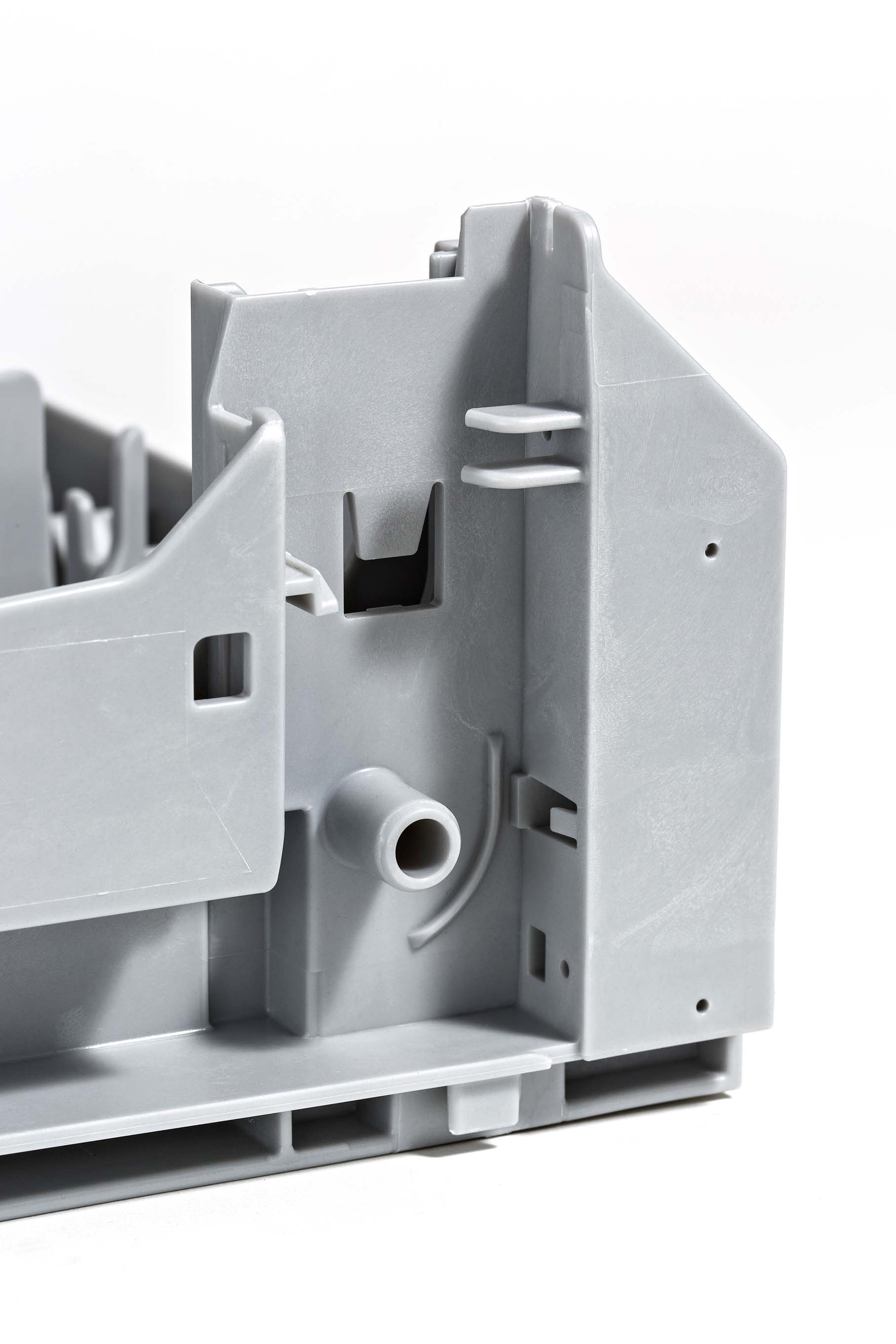

In the context of household appliances, the recyclate could potentially be used as a substitute for the brand-new material that is currently being employed to make injection-molded dishwasher bases. Due to its dimensions (600 x 400 x 100 mm³) and weight of 2 kg, the base can make a huge contribution toward creating a more sustainable overall system if recyclates are used instead of brand-new material. To enable the use of recyclates in the base, various aspects had to be verified, such as the cyclic strength of the most highly stressed area of a bearing dome. This bearing dome is cyclically stressed up to 100,000 times due to the opening and closing that takes place during operation.

Using numeric calculations, the mechanical properties that had been determined from the sample tests were processed so that they could be incorporated into the concept of the most highly stressed volume of material V80 and the concept of the stress gradient χ*. With the aid of component tests and numeric calculations, the level of stress withstandable by the recyclate was compared with the stress withstand capacity identified in the sample tests. This revealed that the recyclate likewise had the structural durability to withstand the cyclic load exerted on the component during operation when measured according to both concepts.

Assuming an annual production volume of 3 million units, approximately 2500 metric tons of crude oil (an inland water vessel with a length of 110 m) can be saved per year due to the resource savings associated with the recyclate. This can make a major contribution to achieving sustainable household appliances.