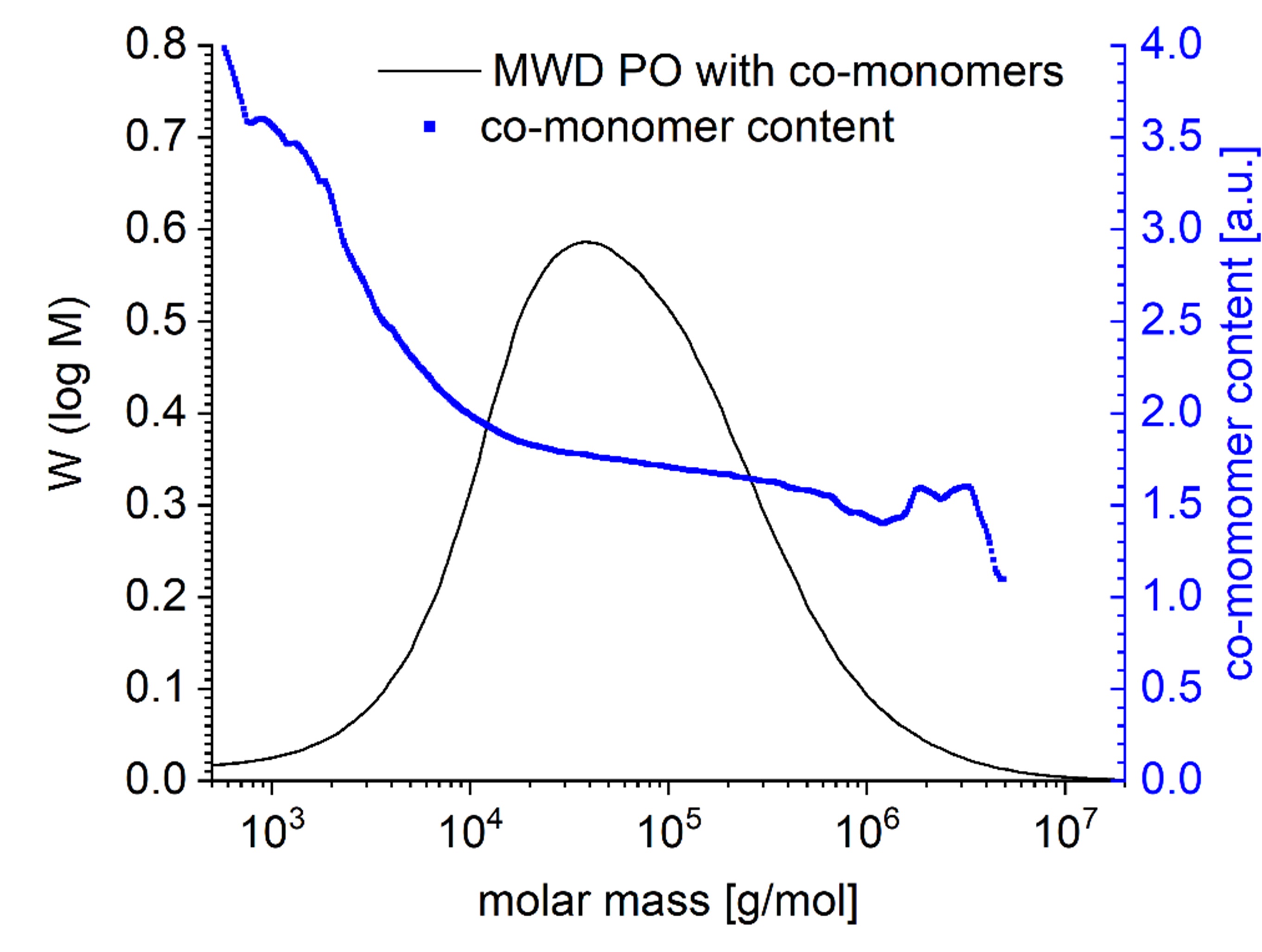

However, the understanding of the molecular structure of the coupling agents obtained in this way is currently incomplete, as there are no suitable analytical measurement protocols for them. The average molecular weights are often determined by intrinsic viscosity measurement or high-temperature gel permeation chromatography (HT-GPC), as it is state-of-the-art for semi-crystalline polyolefins. In the case of maleic anhydride-grafted (MA) polyolefins, the total MA content can be determined by titration techniques or with spectroscopic analysis such as infrared spectroscopy.

Analytical challenges and solutions

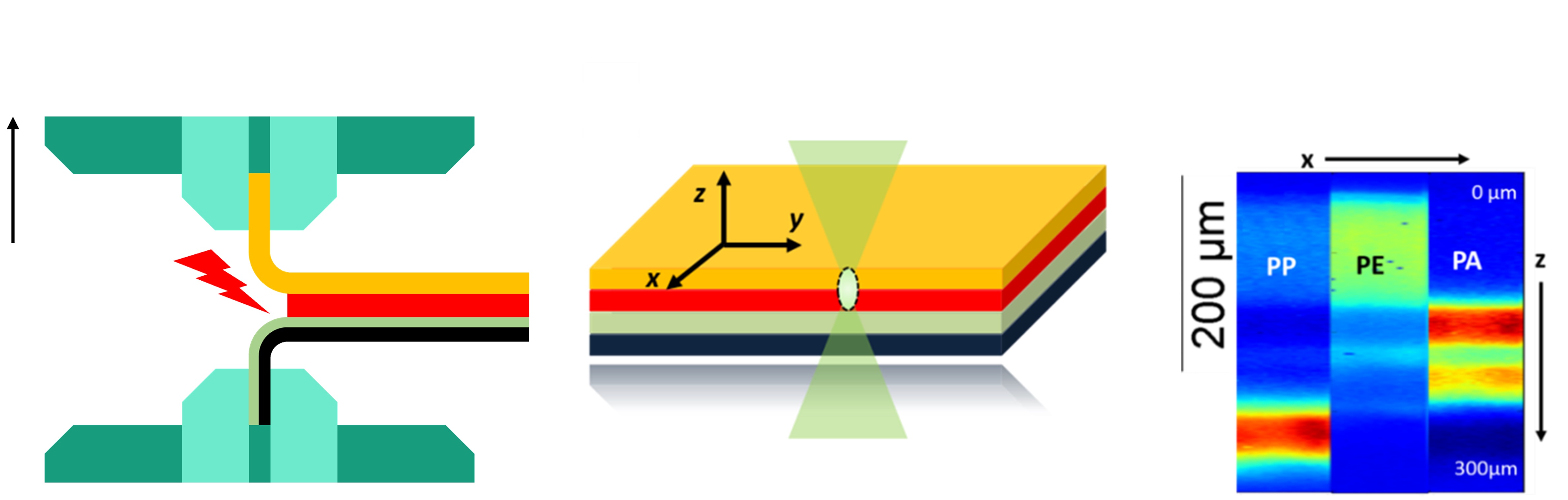

In daily practice, mechanical parameters are used to assess the adhesion behavior of coupling agents. For this purpose, the T-peel test, the 180° peel test, and the climbing drum peel test are widely used. However, their results mainly reflect the properties of the tested system, which, beyond the adhesion behavior of the coupling agents, also strongly depend on the bonding partners, their molding process, and the sample preparation (conditioning). Therefore, the mechanical tests at advanced stages of development bring the most benefits when structures made of composites are to be designed using strength considerations. In contrast, the chromatographic and spectroscopic tests mentioned above, are possible at earlier stages of development, but they provide information on the chemical composition of the coupling agents themselves, while transferability to the system behavior of a composite sample is difficult.

For novel developments aimed at the application areas of plastics recycling, composites, and multilayer films or, for example, photovoltaics, the situation is further complicated by the fact that many different mechanical loads must be taken into account, which may occur in combination. This significantly widens the gap between analytical materials testing and mechanical materials testing. An inherent problem is that tests and current molecular characterization methods do not adequately represent the long-term behavior of coupling agents within these applications.

However, these proposed analytical approaches do not take into account:

(1) the proportion of actually grafted polyolefin,

(2) the distribution of the graft monomer along the molecular weight distribution,

(3) the distribution of the graft monomer between the chains,

(4) the proportion of free graft monomer.

The analytical state of the art leaves the following questions unresolved:

(1) to what extent are mechanical properties and performance influenced by the chemical properties?

(2) Can the mechanical properties be derived from the analytical data?

The information in (1) - (3) is of considerable importance for the determination of structure-property relationships, for the optimization of the grafting process, and for the optimization of processing conditions. The fraction of unused free graft monomers (4) is essential for regulatory purposes. Clarification of the issues (5 and 6) can shorten testing times and accelerate developments.

The goals of the joint project are:

1) Development of analytical methods to determine the molecular structure of graft co-polymers for coupling agents, addressing the contents of items 1 to 4 mentioned above.

2) Measurement data from peel tests shall be systematically compared with analytical data. By identifying a correlation between peel tests and chemical analysis, an estimation of the expected peel behavior from the analytical data should be made possible, according to points 5 and

In addition, the joint project is also intended to offer interested parties along the entire value chain an interdisciplinary platform for developing targeted solutions to the technical problems arising around the topic of coupling agents.

Fraunhofer Institute for Structural Durability and System Reliability LBF

Fraunhofer Institute for Structural Durability and System Reliability LBF