commercial vehicle, drive, defossilization

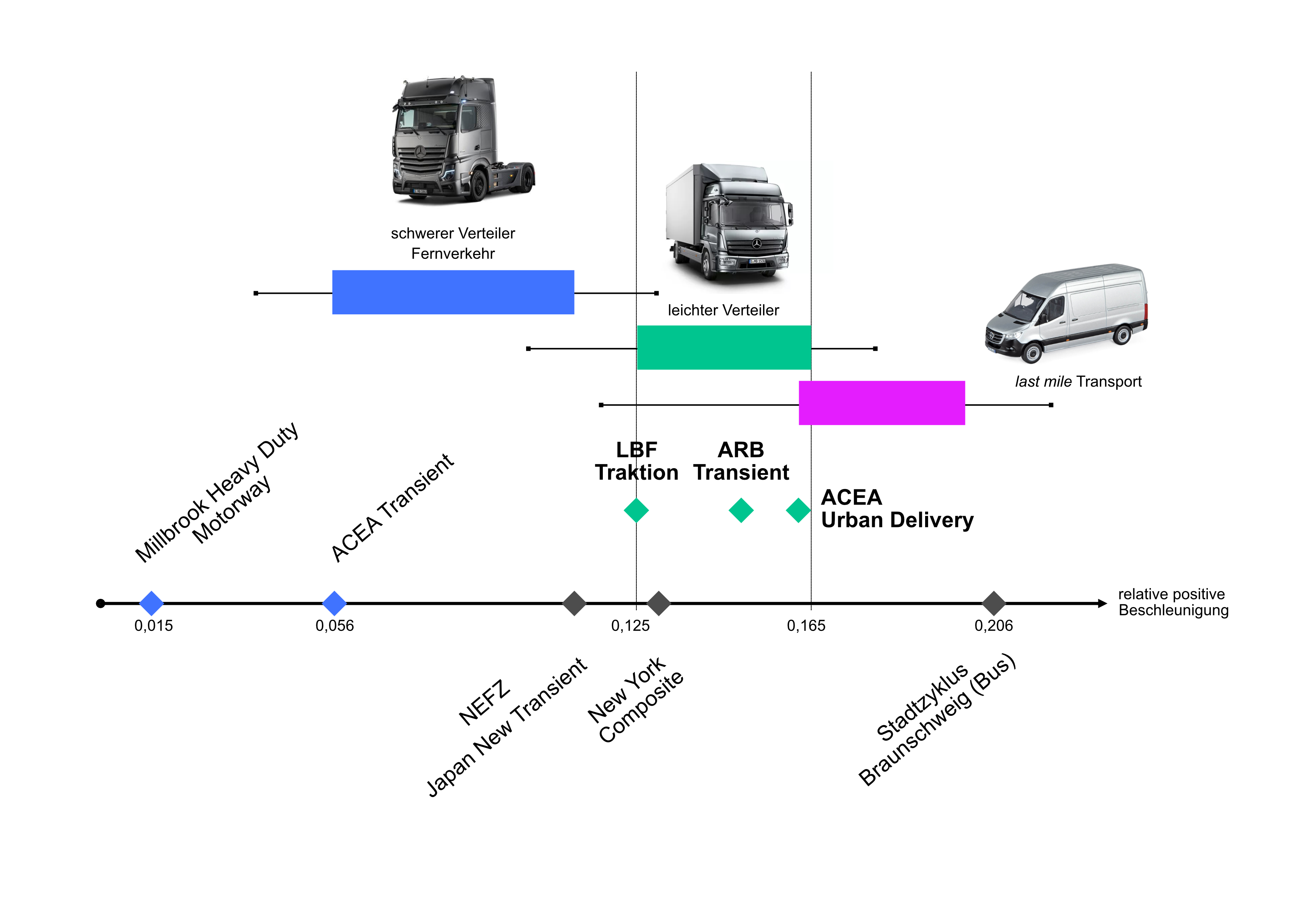

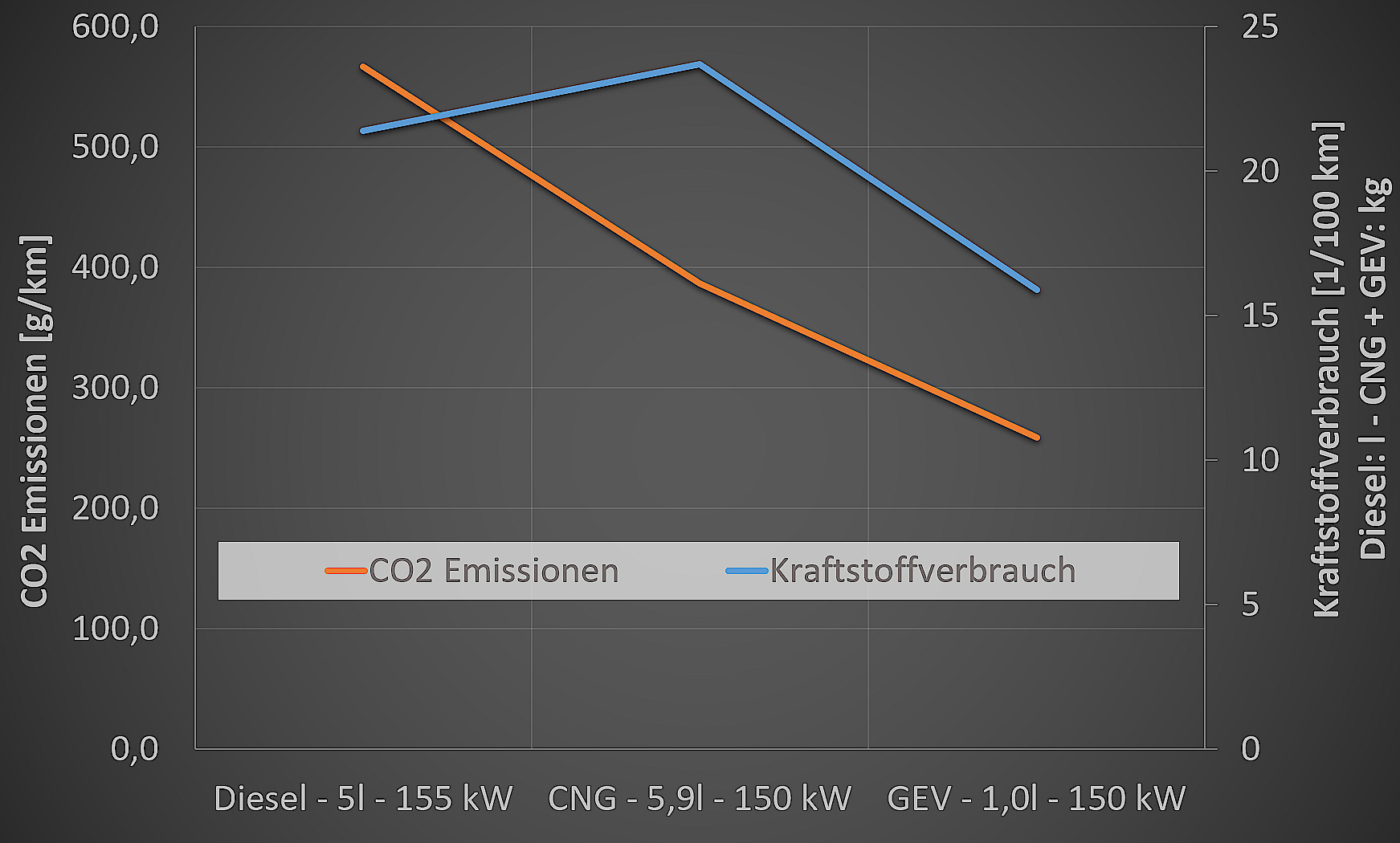

Extensive studies and interviews with freight forwarders were carried out at Fraunhofer LBF to detail the driving routes used for light distribution transport and to allow for them to be compared with existing driving cycles. Electric machines are much more efficient compared to today's standard 5-liter diesel engines, which have outputs of around 150 kW, and so promise an immediate efficiency gain. This represents one of electromobility’s greatest strengths.

The energy efficiency of road vehicles is largely dependent on traction power: Battery electric distribution vehicles require a battery capacity of significantly more than 200 kWh for a driving distance of 200 kilometers, which corresponds to an additional mass of around 2.5 metric tons. Long driving distances therefore make alternative energy storage systems necessary. Hydrogen may represent an alternative, but it will still take some time for this to penetrate the market.

An economical way to achieve to emission-efficient traction energy that is immediately available is the use of generator-produced electrical energy – with the aid of efficient, stationary internal combustion engines for average traction power and electrical machines for converting the kinetic energy during vehicle deceleration. As part of the project entitled “Highly-efficient Powertrain for Commercial Vehicles, Taking into Account the National Mobility and Hydrogen Strategy” (HANNAe), Fraunhofer LBF and Fraunhofer ICT have designed a special generator-electric powertrain optimized for the requirements of light commercial vehicle distribution transport. The power and energy consequently made available for driving the generator-electric vehicle (GEV) is perfectly adequate for typical daily driving distances of up to 300 kilometers and does not impose any restrictions in comparison to conventional diesel trucks.

GEV technology components are particularly efficient in terms of mass and cost. Significantly reduced fuel costs mean that the extra cost of the generator-electric truck can be recouped within two years and CO2 emissions can be significantly reduced. Biogenic or synthetic fuels can be used to further reduce these emissions. The integration of braking energy and high-performance, aging-resistant cells offer further prospects.

Funded by the German federal government’s “Combating Corona Effects, Securing Prosperity, Strengthening Future Capability,” [Corona-Folgen bekämpfen, Wohlstand sichern, Zukunftsfähigkeit stärken] scheme from August through December 2020.