cargo bike, lightweight frame, Tubular Energy System TES, payload monitoring, transport box development, lightweight rims

Commercially-available cargo bikes were used for the initial condition. One aim of the project was to clarify specific opportunities for saving mass on the cargo bike in a practical way. In the case of a tricycle with a Bakfiet structure (see large picutre above), redesigning the frame, along with a change of material from a steel to an aluminum alloy, resulted in the weight of the front end being reduced by approximately 40 percent, or more than 40 kilograms. At the heart of this redesigned frame is a multi-curved aluminum support tube into which a tubular battery system developed for this bike, also known as the Tubular Energy System (TES), is integrated. This is done in a way that is theft-proof and keeps it well-protected from external weather conditions. The battery system originally mounted on the outside of the bike frame provided the rider a capacity of 500 Wh, while the innovative TES contains 80 Li-ion cells and provides a capacity of 1000 Wh.

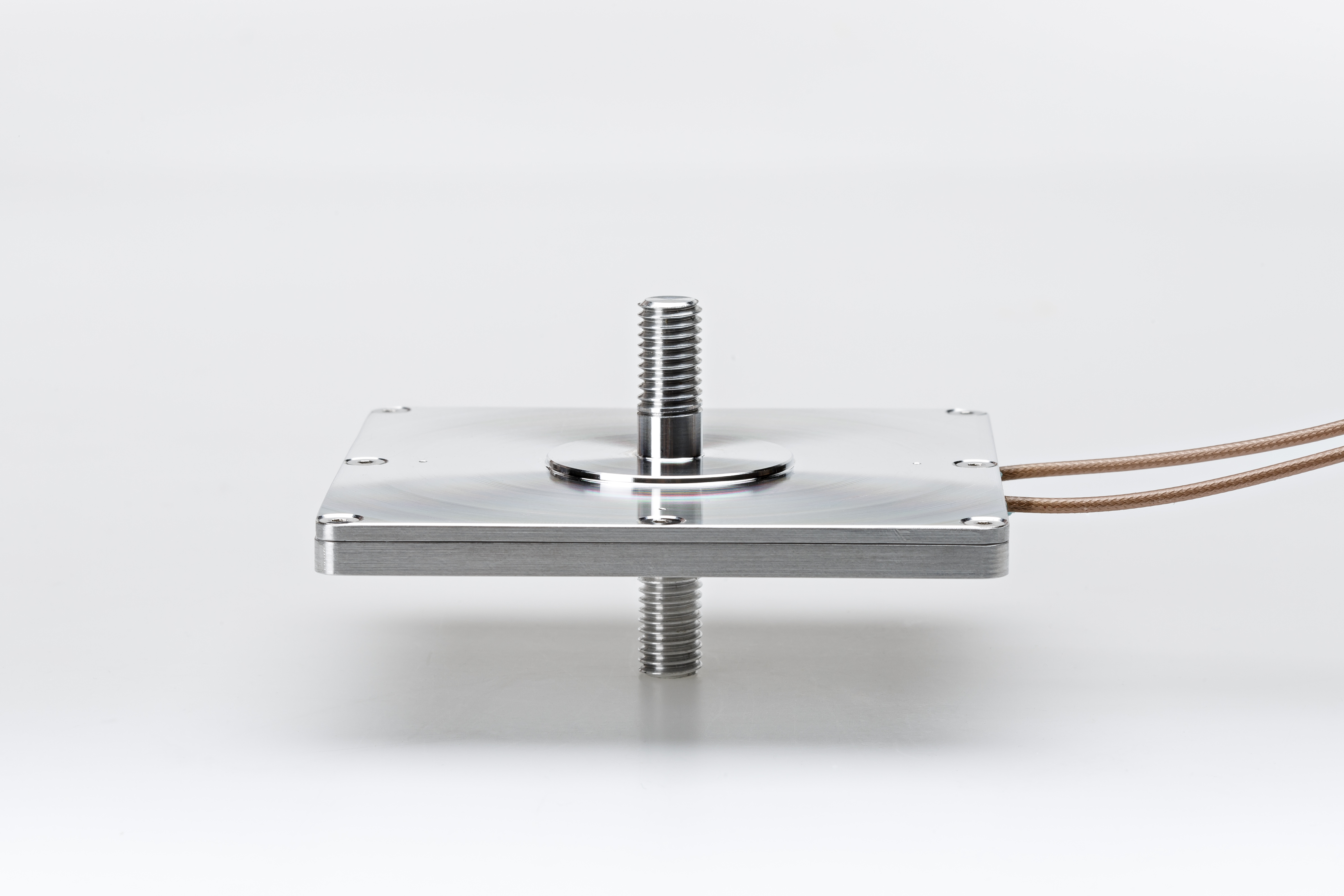

Sensory connecting elements were also developed as part of this project. These are located between the front-end frame and the transport box and serve to ensure a secure connection that can be monitored. The force sensor modules contain capacitive sensor layer systems based on dielectric elastomers. Four of the sensor modules, which are only 8 mm thick, are mounted as connecting elements in the corner areas of the transport box and provide the option of continuously checking the payload, its position and its distribution in the box during the ride. In addition, their high level of sensitivity enables them to measure road conditions, from which further business models can be derived. The sensor data is shown to the rider on a display.

The transport box is an important element in relation to the load. To demonstrate a particularly lightweight solution, a box is being built with additively manufactured bionic structures in combination with carbon fiber reinforced plastics. Crash structures can be integrated for transporting sensitive loads. Moreover, a box made of combinations of biomaterials, e.g. meadow grass with flax fibers, bonded with biopolymer, was constructed as an ecologically sustainable solution, as shown in Figure 4. Due to their thermal-isolating properties, these boxes are ideal for transporting things such as hot food.

The Long John cargo bike shown below left also features an active system to reduce handlebar wobble. With the integrated controlled sensor-actuator system, both ride comfort and ride safety are significantly increased, especially over longer distances. This further increases the acceptance and benefits of this mode of transport.