Assessment of wear susceptibility

The platelet apparatus makes it possible to evaluate the wear behaviour of plastic compounds in melt processing or to determine the resistance of tool steels to given compounds.

The platelet apparatus makes it possible to evaluate the wear behaviour of plastic compounds in melt processing or to determine the resistance of tool steels to given compounds.

For this purpose, two equal-sized cuboid pieces (15 x 12 x 5 mm) of the test material are mounted opposite each other in a frame in such a way that a gap of 10 mm width, 12 mm length and a height of 0.2-1 mm is created through the two plates (Fig. 1). The frame is mounted in a measuring tool, which is flanged to a single-screw extruder.

The melt is extruded through the gap formed by the platelets (Fig. 2). The shear flow in the slot, together with the abrasive and corrosive properties of the melt, causes material to be removed from the platelets. The wear is quantified based the weight loss of the platelets

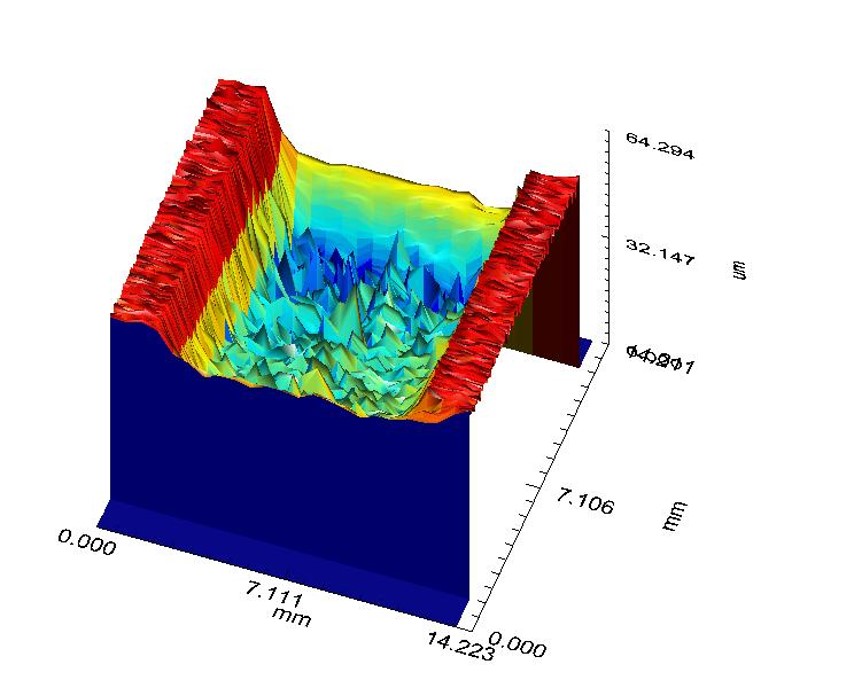

Abrasive melts primarily result in uniform material removal. Corrosive melts usually cause an irregular surface structure. This can be visualised very well using confocal chromatic measurement technology (Fig. 3). For a more detailed metallographic analysis of the wear pattern, SEM/EDX electron microscopy can be used.

To assess the corrosiveness of compounds or to establish a ranking within an ensemble of compounds, we use tool steel 1.2329 (hardened) as standard. This is widely used in plastics processing and can be found in non-return valves, screws and injection moulds. Other steels are also used in consultation with our customers, depending on the specific nature of the compounds to be assessed.

In the comparative evaluation of materials, which may also involve corresponding coatings, our customer specifies the relevant compounds. We can also suggest suitable ones.

The interaction between the plastic melt and the material in the platelet apparatus comes very close to the real situation in plastics processing machines. The suitability of this test method has therefore been demonstrated in numerous bilateral projects with industry as well as in publicly funded projects, both in the development of formulations and in the selection of materials for the housings or screws of plastics processing machines.