New damage model based on failure mode and effect analysis (FMEA)

Electric mobility is crucial for a sustainable future. Advances in battery technologies such as lithium-ion require verification and validation to ensure higher energy densities, safety, and lower costs. The AccCellBaT project accelerates battery development through virtualization, front-loading, and digital twins in combination with physical testing and a new confidence index methodology. Fraunhofer LBF provides support with simulations, service life assessments and risk analyses such as FMEA to increase the reliability of cable harnesses and promote safe, efficient drive systems.

Electric mobility is becoming increasingly important and represents a central pillar for a sustainable future. Accelerating product development and innovation in battery cells and systems is key to the significant market share that battery systems now enjoy in many industries. Every product innovation must be verified and validated before it can be launched on the market and ultimately create added value for the customer. Testing battery cells and systems with innovative Li-ion and post-Li-ion technologies creates the confidence needed to introduce higher energy densities, improved safety, and lower costs. In traditional development, testing only takes place in the late stages of system development. This leads to high risk because problems are only identified late in development, resulting in costly system changes that do not meet the planned market launch date or the expected quality criteria.

Battery development is hampered by a lack of virtualization, resulting in costly physical verification and validation (V&V) activities. The Accelerated Cell and Battery Testing (AccCellBaT) project improves this through virtualization, front-loading, and continuous V&V to optimize battery design, costs, and time to market. The project develops novel physics-based and data-driven simulation models to evaluate the performance, lifetime, reliability, and safety of battery subsystems. These models are complemented by innovative techniques for measuring model parameters and upscaling methods to create digital twins for V&V. Testing of the digital twins is combined with physical testing in a hybrid design verification and validation plan (hybrid DVP). A customized confidence index methodology is introduced to quantify the test results. The processes and methods of the AccCellBaT partners are combined with the hybrid DVP to create a handbook for future battery development. This methodology is integrated into a development tool that supports development and increases automation.

To ensure a safe and reliable product despite accelerated development cycles, Fraunhofer LBF is working on various aspects such as the simulation of wiring, the evaluation of fatigue life and the reliability and safety of connectors, cable harnesses, and battery modules and systems. A central focus is on the digitalization of operating loads in order to create realistic load profiles that contribute to the optimization of the systems. Fraunhofer LBF also supports the verification and validation (V&V) of battery systems to ensure that they meet safety and performance requirements. Through these comprehensive approaches, Fraunhofer LBF contributes to supporting the development and use of modern electric drive systems and increasing their efficiency and reliability.

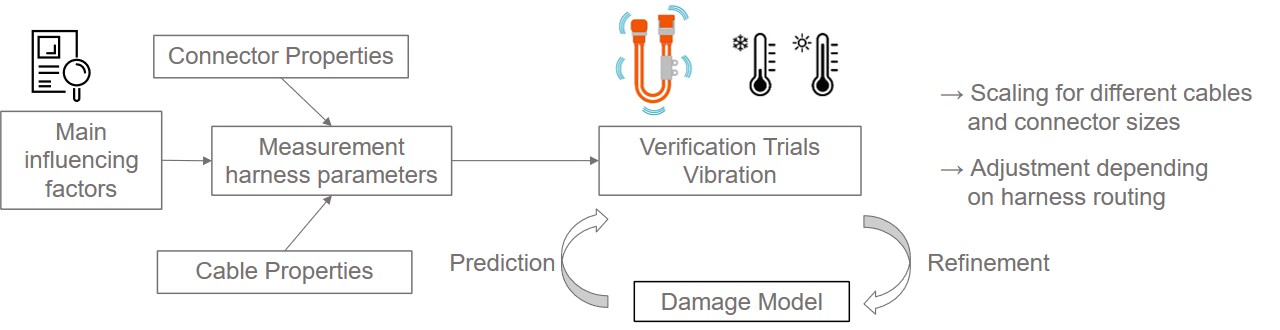

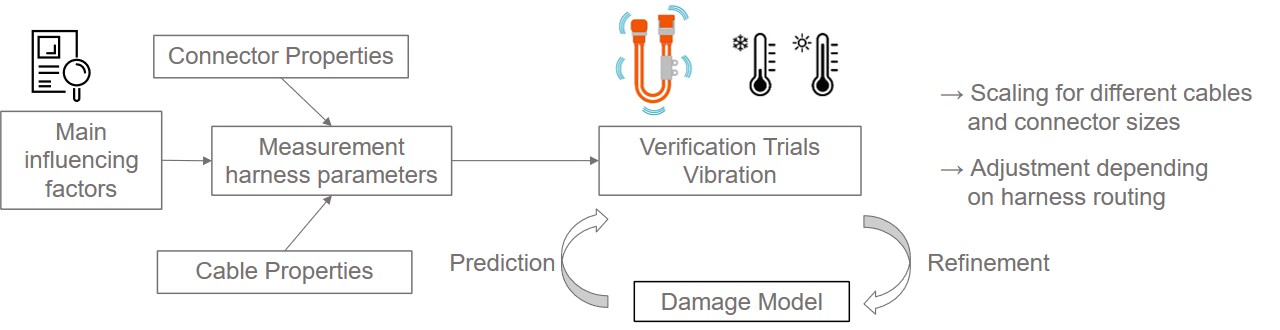

As part of the risk analysis, relevant factors influencing the damage model (environment, application loads, material properties) were identified that affect the durability, reliability, and safety of each individual component of the cable harness. For this purpose, a risk analysis based on a failure mode and effects analysis (FMEA) was carried out and causes of failure were systematically identified. The risk was assessed based on the probability of occurrence, detectability, and severity of the consequences. Based on this analysis, which focused on aging phenomena, the main damage drivers and modes were defined, which made a significant contribution to the development of a damage model at the component level, which will then be verified.

Funding body: European Union

Grant No. 101103628 – https://cordis.europa.eu/project/id/101103628

Partners