Hybrid battery architecture for ships

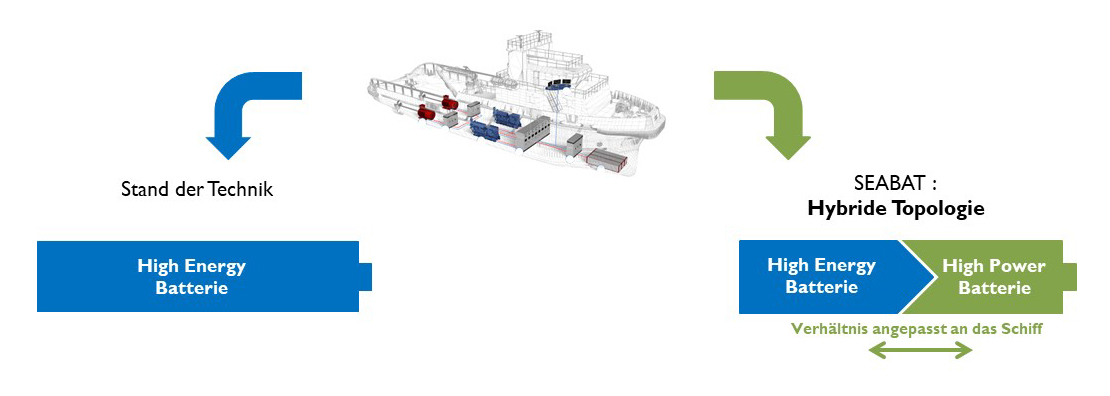

Battery solutions for ships are usually tailor-made and, if at all, for small series, which leads to high costs. In addition, a single battery type is used both to cover the high energy requirements, e.g., to maintain cruising speed, and for high power peaks, e.g., when loading in port. However, a single cell technology cannot meet both requirements. As a result, batteries are oversized by a factor of 2 to 10, which also leads to high costs.

The EU joint project SEABAT has developed a hybrid concept based on the combination of high-energy and high-performance batteries with a novel converter concept.

The hybrid battery system consists of three architectural levels: module, string, and system. The system level encompasses the entire battery system and regulates the various strings. Each string manages individual modules to provide the appropriate DC voltage, while each module, whether high-energy or high-power, regulates the respective lithium-ion battery cells.

At the heart of the system are the battery modules, of which there are two types: high energy (HE) and high power (HP). The main difference lies in the cell technology used, namely NMC and LTO. On the BMS side, each module consists of a master and slave system and a DC/DC converter.

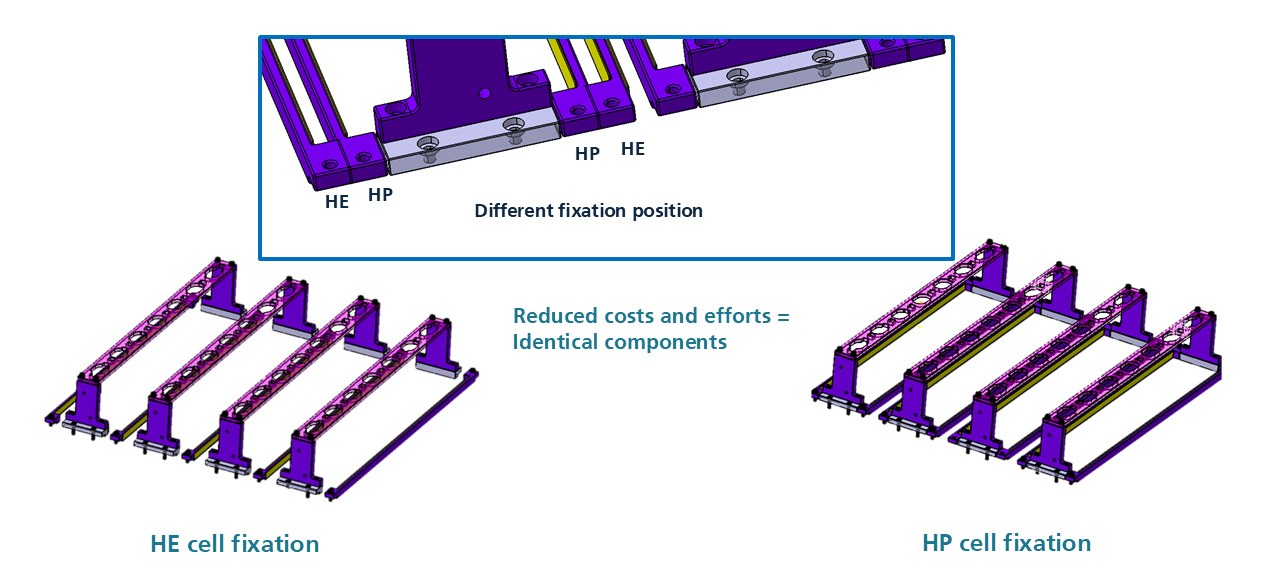

The design of the SEABAT modules is based on the platform design familiar from the automotive sector, which uses identical components and assemblies for both module types (HP and HE). The approach of using as many identical parts as possible results in lower costs, both in terms of hardware and assembly.

The two module types ultimately differ only in the type of lithium-ion cells (HP or HE) and the associated routing of the electrical connection rails (bus bars) and the circuit boards for cell monitoring. All other components, such as the housing, cooling system, DC voltage converter, cell fixation, electronic boards, holders for fixing other components, and even the screws, are identical. The two cell types with their different dimensions are fixed in place by centering and a central, identical mounting unit. They are also fixed on the sides by different positions of the side cell mountings in the module. The component itself for side cell mounting is the same for both module types.

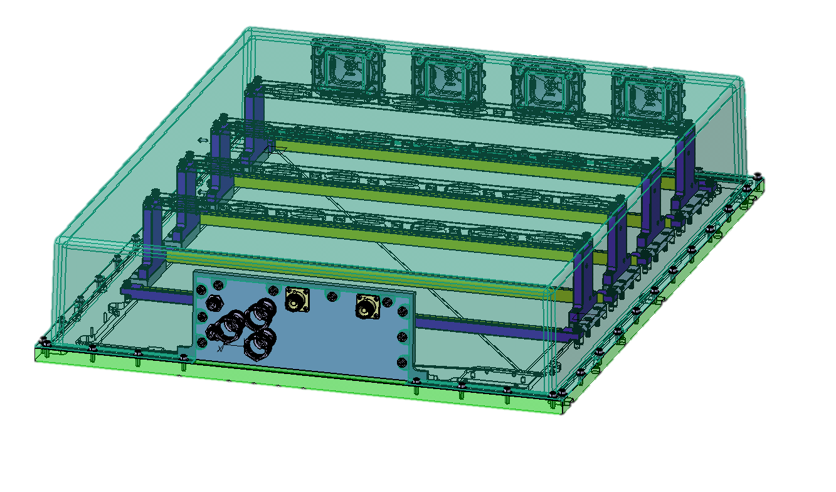

The module housing itself consists of three components made of different materials: an aluminum base plate, a sheet steel and thermoset cover, and an aluminum interface plate for the electrical connections. A lightweight, two-layer design was chosen for the module cover. The inner layer consists of a so-called ablation material, which in this application is a thermoset with mineral fillers reinforced with aramid. The outer layer is chrome-nickel sheet metal. The ablation material is sacrificed under the influence of hot abrasive media, such as the particle-laden gas jet that is ejected from a lithium-ion cell during thermal runaway. This ensures the mechanical integrity of the sheet metal cover in the event of such an incident.

Based on the results of cell-level tests conducted at CEA, such as overcharge and overtemperature tests, the housing was designed to include safety vents to blow out the gases generated during thermal runaway.

To validate the housing design, a thermal runaway was triggered at the module level for both module types at the project partner CAE. The results met all expectations and both module types successfully passed the test.

This project has received funding from the European Union's Horizon 2020 research and innovation program under grant agreement No. 963560. The Seabat project consortium consists of 15 partners from 8 different EU and associated countries.