Basics

In CRM, a laser is focused on the polymer sample, exciting molecular vibrations that are specific to the chemical bonds in the material. When the laser light interacts with the sample, a small portion of the scattered light shifts in wavelength according to the vibrational energy levels of the polymer's molecules - a phenomenon known as the Raman effect. This shifted light is collected and analyzed to produce a Raman spectrum that provides detailed information about the chemical composition and structure of the sample.

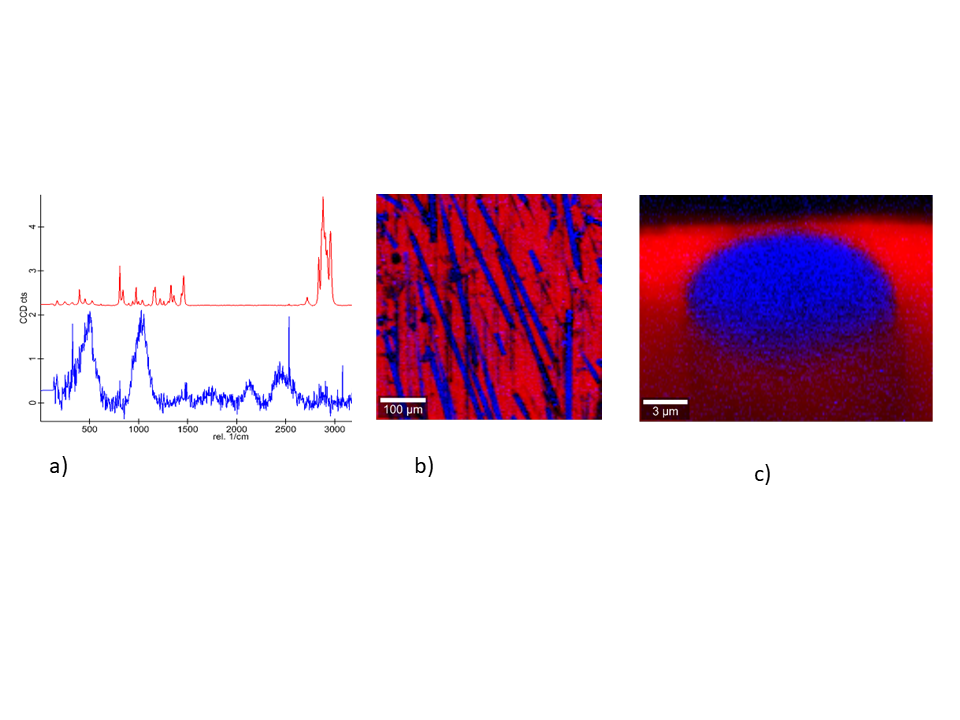

As a key feature, CRM uses a confocal pinhole aperture so that only light from a very small volume of the sample reaches the detector. By scanning the sample in three dimensions, CRM thus creates a high-resolution chemical map that enables in-depth analysis of polymer properties such as phase distribution, crystallinity and chemical composition without the need for time-consuming mechanical sample preparation. This high spatial resolution makes CRM particularly valuable for understanding complex polymer structures, quality control and the investigation of material behavior under different conditions.