Optimization of castability, lightweight design, operational stability and testability

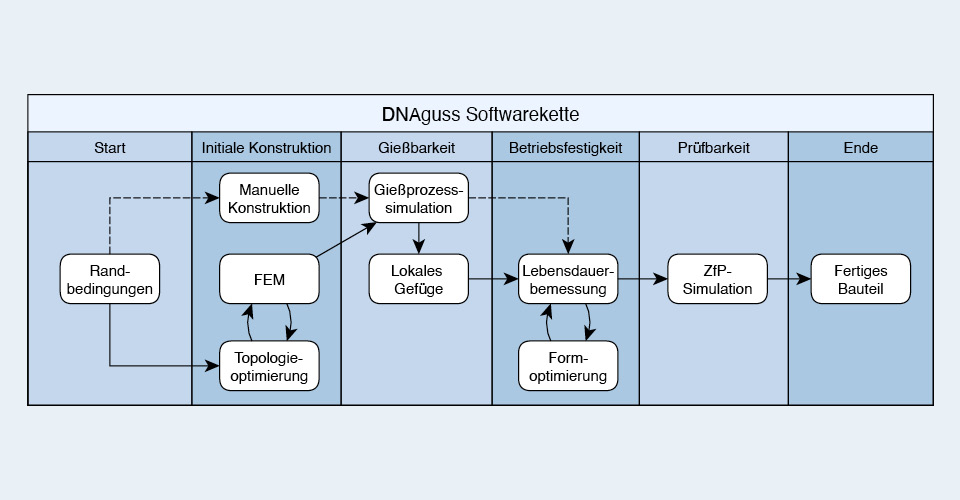

The DNAguss project takes an interdisciplinary approach that combines topology and shape optimization, casting process simulation, structural mechanics and fatigue strength to optimize the design of cast components in terms of lightweight construction.

One of the most important steps in the design process is the situation analysis, in which the installation space, the forces to be transmitted and other boundary conditions are defined. This serves as the basis for creating the CAD model by means of topology optimization. In this process, the structural-mechanical simulation is carried out in Permas. The advantage of topology optimization is that basic requirements for castability and testability can be taken into account automatically, enabling a material-saving design. Alternatively, manual design or the use of a previously designed component is also possible.

After the CAD model has been created, the castability of the component is ensured by a casting process simulation in Magmasoft. This also calculates the local microstructure composition, which can be used later in the software chain.

This is followed by the shape optimization, in which the fatigue strength is integrated into the shape optimization loop with the aid of FEMFAT and used as a tool for the fatigue strength calculation. Either a local or global microstructure with the corresponding material definitions can be selected.

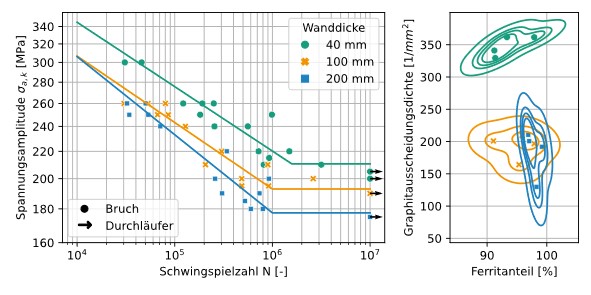

Based on the results of Magmasoft, test and metallographic data, the local fatigue strength can be determined via a correlation equation as a function of the local microstructure composition. This enables targeted weight optimization while at the same time ensuring operational strength. The use of a local material definition is particularly useful for components with locally different cooling rates, since the microstructure can vary greatly within the component. Different cooling rates can result, for example, from different wall thicknesses. A low wall thickness leads to a short cooling time. As a result, a microstructure with a high graphite precipitation density is formed, which leads to higher stressability. In addition to the graphite precipitation density, the ferrite/pearlite ratio has an influence on the stressability. A high ferrite ratio leads to lower stressability, see Figure 1.

In summary, DNAguss shows how the design of cast components can be revolutionized by linking advanced software tools. By integrating all software tools used in design into a single software chain, castability, lightweighting, fatigue strength and non-destructive testability of components can be optimally matched. This enables improved structural design, weight reduction and lowering of manufacturing costs while ensuring operational stability.

sponsored by: Federal Ministry for Economic Affairs and Climate Action

Partners Science:

Partners Industry: