With ultrasound, mechanical properties can be examined at high frequencies. Ultrasonic measurement techniques allow non-destructive examinations at measurement frequencies between 1 MHz and 100 MHz with rates of up to 1000 measurements per second. Typical applications are monitoring of:

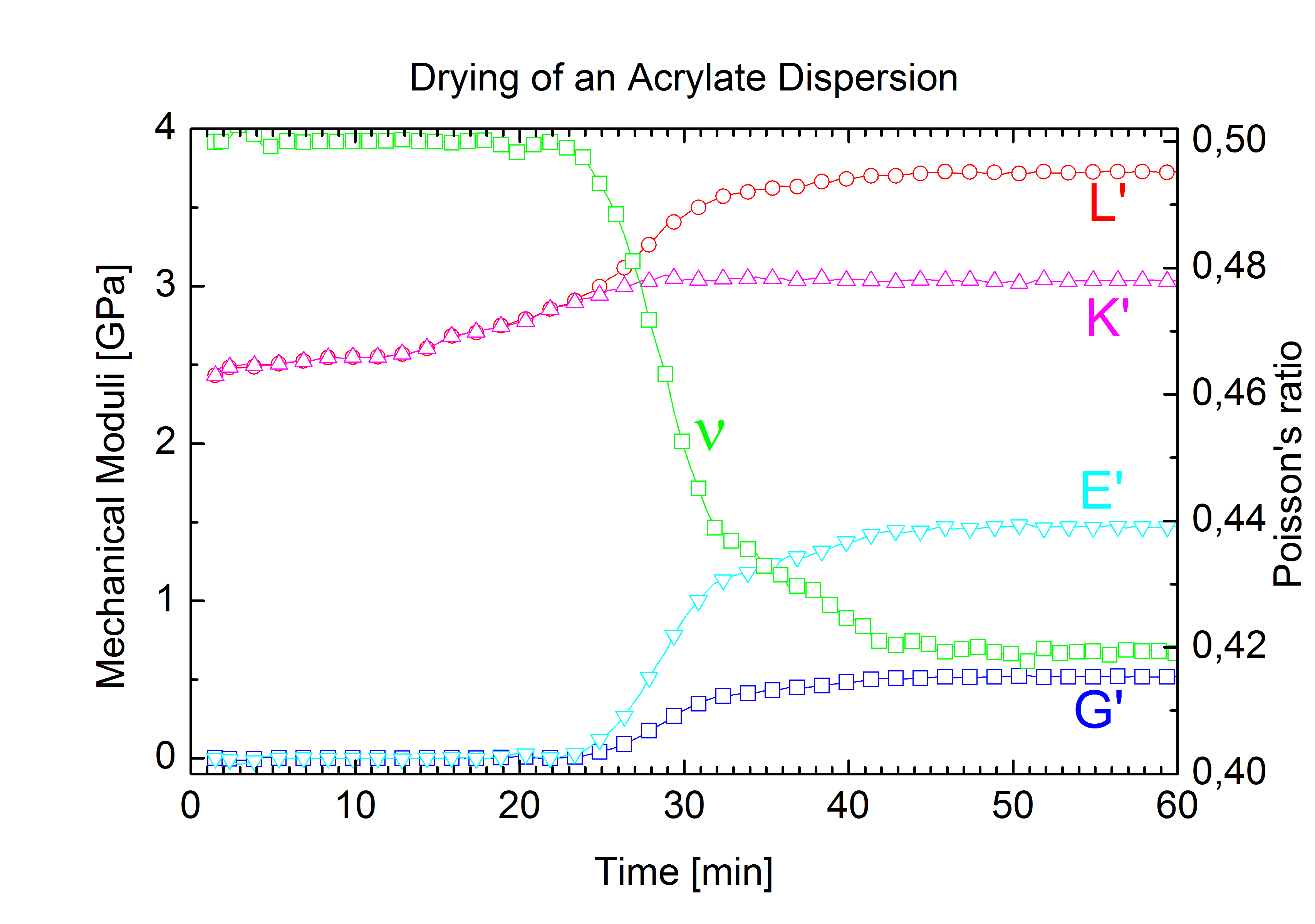

- Drying and curing of paints and varnish (water or solvent based)

- The hardening of adhesives (acrylates, polyurethanes, epoxy resins, UV)

- Crystallization processes

We offer ultrasonic measurements in reflection or transmission, the examination of various issues and the adjustment of these specialized methods to your needs.