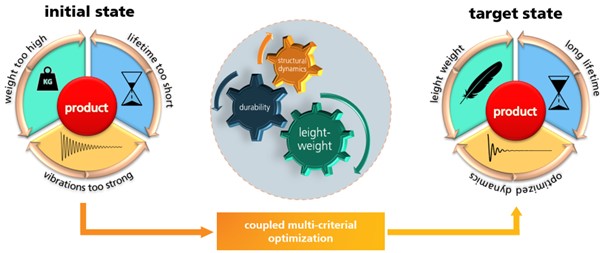

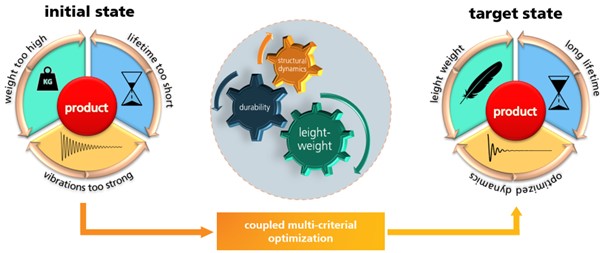

Methodology for the holistic and efficient optimization of products

Fraunhofer LBF is valued by its customers as a proven partner in the fields of vibration control and fatigue strength and is increasingly perceived as a strategic partner for lightweight construction and sustainability. In order to develop sustainable products and leverage lightweight design potential, both the structural dynamics and the fatigue strength of structures and assemblies must be considered and optimized simultaneously. The institute has many years of expertise and established tools for both issues, but they are usually used separately. Since, especially for medium-sized companies, structural optimization and service life assessment are technically and economically coupled and linked in terms of personnel, a tool is now being developed as part of the DuraDyn project that enables attractive offers for the holistic and efficient optimization of their products. In this way, the customer's wish to implement the "one-face-to-the-customer principle" can be met.

The core of the project is the development of a numerical method for the simultaneous optimization of structural dynamics and service life of components and systems in a single calculation process. For this purpose, the parametric model reduction is extended by the consideration of modal stresses at critical positions. With these modal stresses, the service life is reliably evaluated via rainflow counting and a subsequent linear damage accumulation. Since, due to the non-linear system behavior and despite the model reduction, the computation times are relevant and each verification point represents an increase in the degrees of freedom, a reliable fatigue assessment with as few input variables as possible is required. This is done using the example of welded joints. The detail of the welded joint was chosen deliberately, since a local evaluation based on maximum stresses and stress gradients is indispensable here, but these quantities cannot normally be determined from the reduced models. The methods for the optimization of dynamic systems with passive and active measures (such as stiffeners, vibration dampers or inertial mass actuators) are then extended to include the evaluation of service life, so that, for example, required minimum service lives can be specified as an additional constraint for the optimization. The validation and demonstration of the methodology is carried out on the basis of application scenarios close to industry, whereby structures from agricultural machinery construction are considered in particular.

with regard to service life of critical weld seams (left) and structural dynamics (right) by optimizing the parameters of a vibration absorber (above)with regard to service life of critical weld seams (left) and structural dynamics (right) by optimizing the parameters of a vibration absorber (above).