GreenMat4H2 - Customized »green« materials for »green« hydrogen

For the production, storage and use of hydrogen, a large number of elements, materials and systems are required, which must be investigated in detail with regard to their service life and criticality and offer scope for optimization as well as substitution. Within the performance center, the materials used are therefore evaluated with regard to their ecological footprint and suitability on the one hand, and their integration and use in efficient and high-performance systems is enabled on the other. Sustainable alternatives for materials used must be identified and their application in product solutions ensured. For this purpose, the entire life cycle of products and systems of a hydrogen economy must be considered, from production, storage and transport to use and recycling. In addition to the materials used, components and systems are also analyzed in terms of their reliability and sustainability, and new recycling and circular economy concepts are developed. In this way, the hydrogen economy will not only become more sustainable and geopolitically independent, but also more efficient and safer.

Life cycle of hydrogen-related systems: production, storage, transport and recycling

Even though the energy used to produce hydrogen comes primarily from renewable sources, catalysts and membranes in electrolyzers that contain rare earths or critical metals such as platinum, cobalt or iridium are usually used to generate hydrogen. This is where the researchers at the performance center are tackling three issues: First, new synthesis routes are being researched in which the critical components are substituted by recyclates, among other things. Secondly, the scientists are looking in detail at the recycling, upgrading and recovery of the technology used to produce hydrogen. Third, an overall system approach is being taken to optimize the safety and reliability of products such as fuel cells, pipelines, electrolyzers and storage systems. The aim is to achieve the highest possible efficiency, service life and safety in components and systems that are charged with or carry hydrogen, while making the greatest possible use of resources.

Hydrogen itself is well suited to absorbing energy peaks in renewable energies and storing excess energy. However, hydrogen cannot always be used where it is produced. As part of the performance center, researchers are therefore working on various ways to optimize storage systems and their peripherals in terms of operational stability and sustainability. This is done, for example, for high-pressure tanks, solid fuel storage systems, in technical systems in the context of hydrogen liquefaction and for piping systems with special requirements for corrosion resistance under additional oscillating stress. In this context, the materials, components and systems are analyzed in detail with regard to their load, stress and stressability. At the same time, the materials used are examined for their criticality and processes are developed for substitution and upgrading, for example with recyclates, and for recycling.

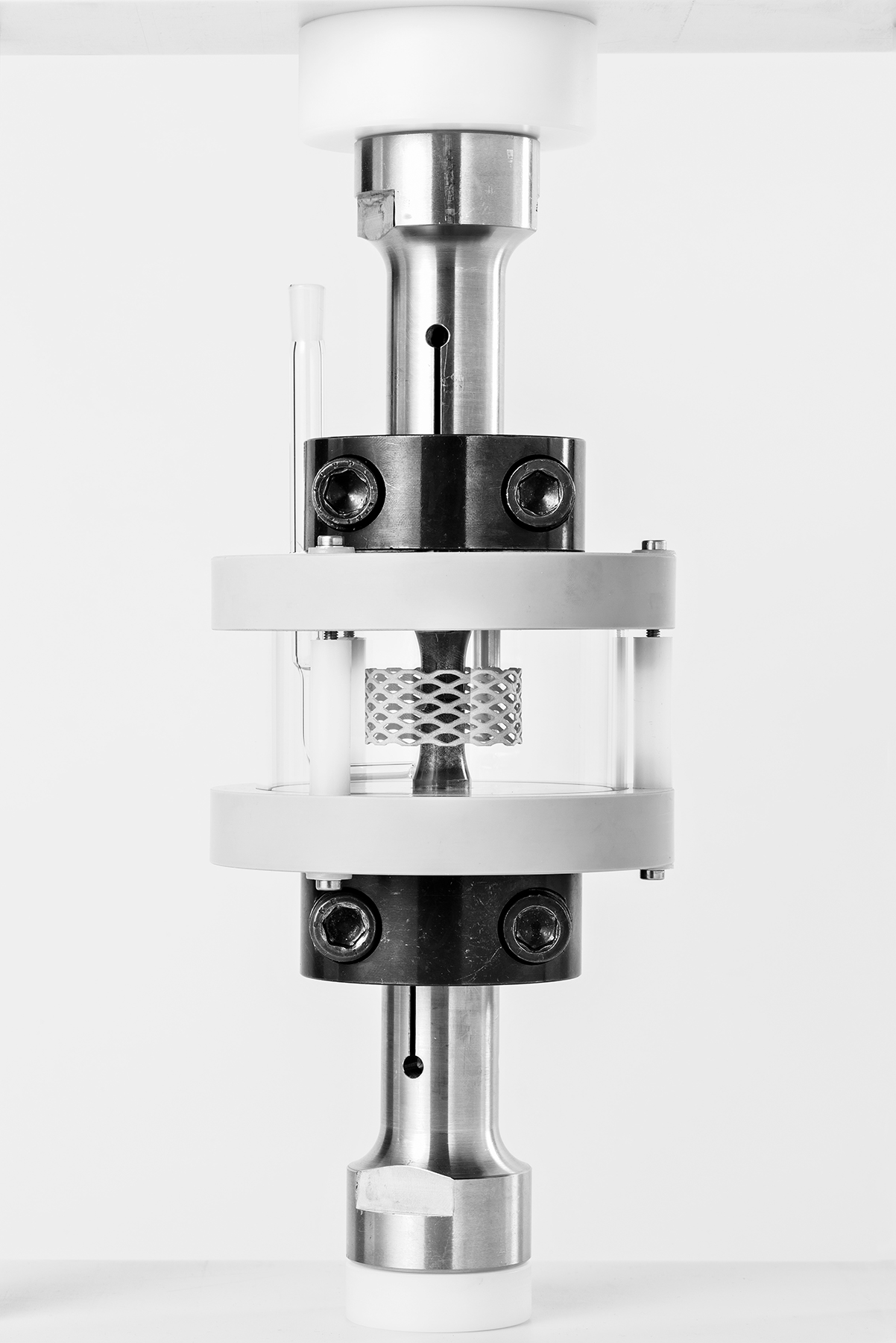

The third pillar in the hydrogen life cycle is utilization. To use hydrogen electrically, fuel cells are primarily used for energy conversion, especially in hydrogen-powered vehicles. However, especially in the area of commercial vehicles and freight transport, the stress capabilities as well as service lives of fuel cells and the hydrogen-carrying components have not yet been sufficiently investigated, which hinders targeted optimization with regard to efficiency, lightweight construction and material utilization and thus the efficient use of hydrogen technology. In addition, the components of these propulsion systems contain valuable technology metals such as platinum or ruthenium, which must be recovered and recycled after the end of operation. The latest developments such as solid oxide, molten carbonate or polymer electrolyte fuel cells are also being considered within the performance center in terms of their environmental footprint. "We are proud to lead this pioneering project together with the Fraunhofer LBF. Hesse and especially the Rhine-Main region with its competence in materials science is the ideal location for the performance center. We want to bundle this expertise and make it available for the development of a hydrogen cycle economy in Hesse," explains Prof. Dr. Anke Weidenkaff, head of the Fraunhofer IWKS.

"It is important to us to involve stakeholders from industry, research, politics and society in order to find practicable application solutions," adds Prof. Dr. Tobias Melz, head of Fraunhofer LBF. The performance center was launched in the second quarter of 2021. In addition to research, an important task of the performance center will be the transfer of results to a high level of technology readiness, which is why partners from universities and research institutions as well as SMEs and industrial companies will be involved. Initially, the performance center will be fully integrated into the existing infrastructure of the participating Fraunhofer institutes. With the further operationalization and implementation of exploitation measures of the performance center (planned from 2022) as well as the integration of further partners, a continuous continuation in terms of rapid technology transfer to industry is intended.