Non-destructive testing for detecting material damage

Recycled carbon fiber (rCF) composites play a key role in sustainable material development. The RE-IMPACT project investigated an innovative testing method based on the electromechanical impedance (EMI) method to detect structural changes at an early stage. The aim was to develop an EMI inspection system for quality assurance of these materials in industrial applications. By combining mechanical tests with EMI measurements, correlations between structural changes and electrical signatures were identified.

Recycled carbon fiber composites (rCF) are becoming increasingly important in industrial manufacturing, particularly in the automotive and aerospace industries. They offer a sustainable alternative to conventional carbon fibers by conserving resources and reducing environmental impact through recycling. Quality assurance for such materials poses a major challenge, as their mechanical properties are highly dependent on production parameters and the composition of the recycled fibers. To ensure the reliability of these materials and increase their industrial applicability, a non-destructive testing method based on the electromechanical impedance (EMI) method was developed as part of the RE-IMPACT project.

The aim of the project was to design an inspection system that detects structural changes in rCF materials at an early stage by analyzing electrical signatures. This should enable continuous monitoring of material quality in order to identify defects during production or later use in good time. In the long term, such technology contributes to improved production reliability and more efficient use of rCF composites in industrial applications.

The EMI method is based on coupling a piezoelectric transducer to the structure under investigation. An alternating voltage is applied to generate vibrations whose signature provides information about the mechanical properties of the material. Changes in impedance can thus provide indications of structural defects.

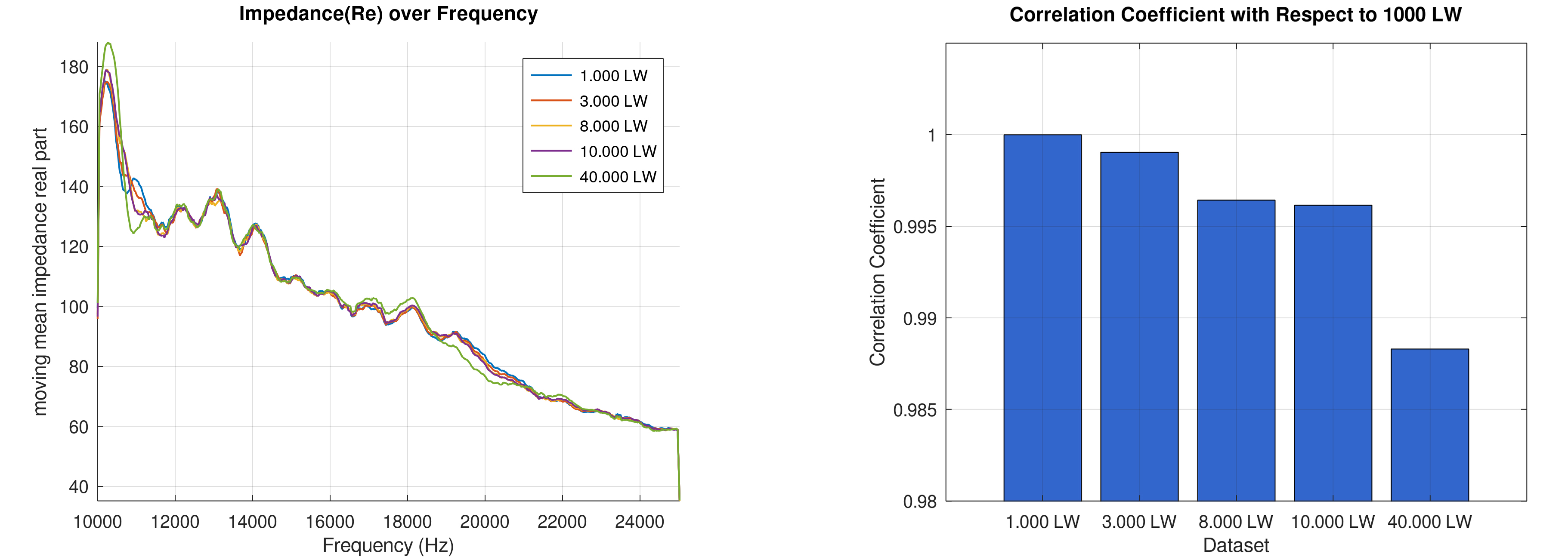

As part of RE-IMPACT, a prototype of the EMI inspection system with a software environment for data acquisition was developed and evaluated in various test series. The investigations included both static and cyclic load tests, in which rCF composites with different fiber volume contents and surface weights were analyzed. The extent to which structural changes such as microcracks or fatigue phenomena can be detected via impedance measurements was examined.

During the course of the project, it became clear that EMI technology is suitable for quality monitoring of rCF composites. The test concepts developed have shown that continuous monitoring of material changes is possible using the EMI method. The sensitivity of the measuring system for certain types of defects will be further improved in the future and the system will be adapted to industrial applications in pilot projects.

RE-IMPACT has provided valuable insights into the possibilities and limitations of EMI technology for rCF composites. The research results contribute to further technological development and provide the basis for sustainable material applications in industry.

BMBF and Eureka Network