Real tire wear – from rapid generation to degraded molecules

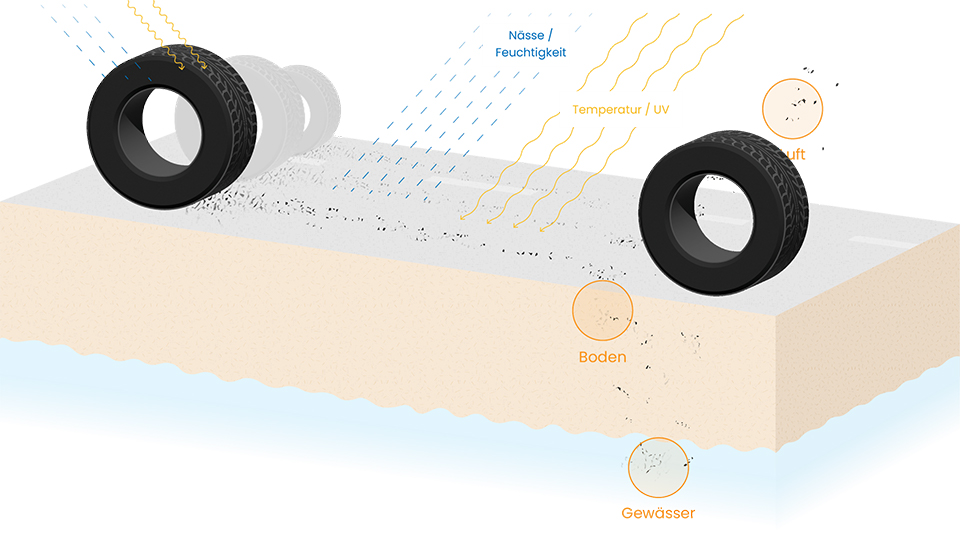

Tire abrasion caused by daily transportation and its decomposition products represent a major burden for humans and the environment. The Euro 7 standard introduces fine dust-related limits for tire abrasion for the first time, requiring the industry to significantly reduce these and make them more environmentally friendly.

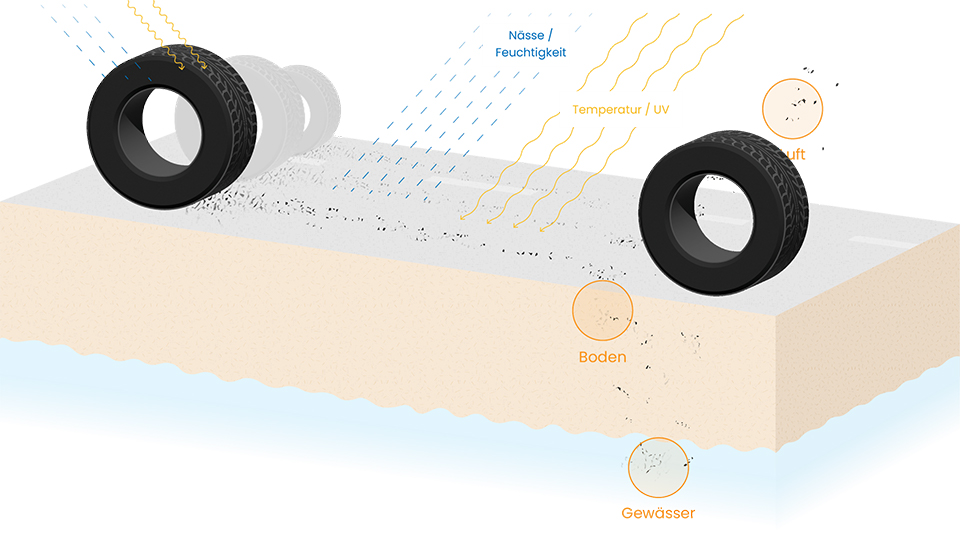

Existing test methods focus only on the quantitative wear resistance of tires. The shape, size distribution, and their influence on the degradation processes of particles in the environment and their toxicology are not taken into account. In order to close this regulatory-driven market gap through pre-competitive research, cross-institutional and competence-pooling cooperation between Fraunhofer LBF, IWM, IGD, and ICT is required, all of which are already working on individual aspects of the topic of tire abrasion.

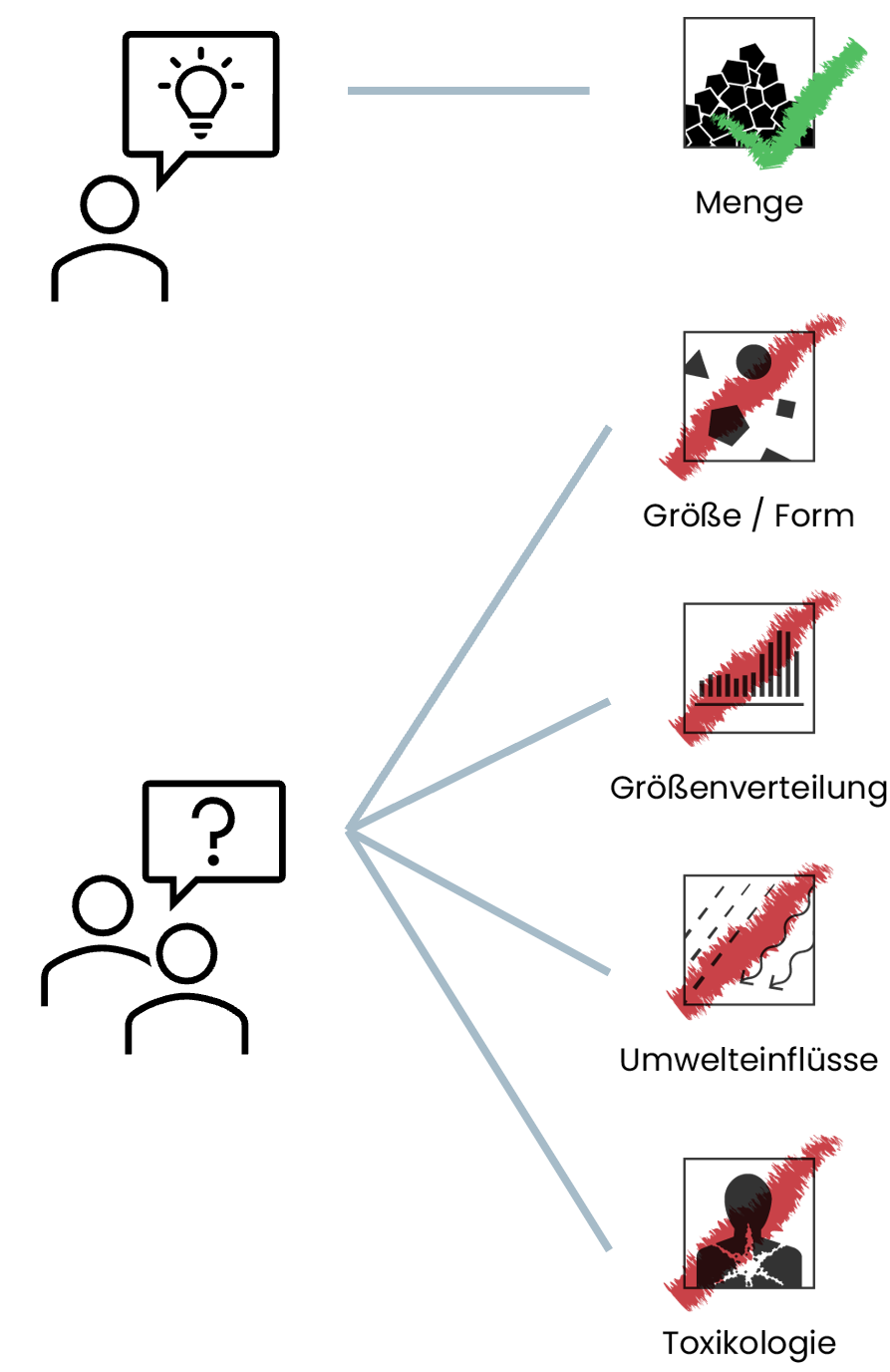

A technology platform is being developed to generate realistic rubber abrasion, the analysis of which will be used for material and tire development and for forecasting digitized driving analysis. This requires the development of a parametric friction surface and the generation of real reference particles. The degradation of the realistic abrasion produced is being investigated using new laboratory weathering techniques and chemical analyses. The results are used for ecotoxicological assessments and also transferred to vehicle fleet simulations.

Laboratory-based generation of realistic abrasion and analysis of particle degradation form the basis for standardizable testing and prediction of the emission tendency of materials at an early stage of tire material development without having to manufacture a complete tire and collect abrasion during driving. Material adjustments to optimize particle distribution and degradation can thus be made in much shorter cycles and with much less effort. In addition, the analysis results form the basis for human and environmental toxicological investigations, which are only possible with these results. The integration of tire wear and particle emissions into vehicle simulations and the development of a tribological model to describe wear particle formation expand digital applications and enable holistic optimization.

The overall objective is to develop a technology platform for new tire compounds. Realistic abrasion is generated on samples, collected, classified using AI, the particle sizes are predicted, and then weathered and analyzed.

The following sub-goals contribute to this:

Development of a methodology for generating standardized reference abrasion, which includes the collection of suspended and sedimenting particles under realistic driving conditions from the GRIPS test bench. Characterization of the collected particles in terms of size and shape, and implementation of a holistic method for investigating the aging processes of elastomers, including ozone, UV stress, and mechanical stress, with the aim of providing a defined reference standard.

Tribological abrasion testing on micro-samples, with simple integrated volume flow control for separating and collecting sedimenting or suspended particles for preliminary analysis during modeling and development of friction surfaces for the multi-axial abrasion machine. Physically motivated extrapolation of wear and emission coefficients for digital prediction.

Methodology for optical detection of the tread and rapid AI-based classification of tread structures in the abrasion test bench, as well as correlation of surface structures with the size distribution of abrasion particles.

Development of an industrially applicable and standardizable detection method for weathering-induced VOC and SVOC from tire abrasion using commercial weathering and analysis equipment, and creation of a corresponding catalog of procedures and guidelines.

Development and integration of approximation functions for emission forecasting for vehicle simulations to predict tire wear and particle formation depending on driving maneuvers and road surface profiles, and to develop abrasion-reducing driving maneuvers based on driving condition-specific tire emission forecasts.

The TERIS project is funded by the Fraunhofer Society as part of the PREPARE program. This program supports innovative research projects within the Fraunhofer Society that aim to develop groundbreaking technologies and solutions that can be used in a wide range of applications.

The following institutes are involved with their respective areas of expertise: