Sports car prototype in endurance test

This method of validating fatigue strength is used in the same way for sports and racing vehicles. Differences arise in the load when the vehicles are used. In racing use, significantly higher and more frequent lateral and longitudinal accelerations occur in relation to those in normal road traffic. This must be taken into account when determining the load assumptions and thus when specifying the load time series for the proof test on the test rig.

At Fraunhofer LBF, a fatigue strength analysis of the chassis, monocoque and other safety-relevant structural components was carried out for the Porsche 963 sports car prototype. The Darmstadt specialists worked closely with those responsible for fatigue strength at the motorsport department of Dr. Ing. h.c. F. Porsche AG (Mr. Rieser) and for the operation of the chassis dynamometers at Porsche AG (Mr. Ruder). With the LMDh 963, Porsche is returning to the league of endurance racing and used the race car for the first time in the 2023 24-hour race at Daytona. The race car is powered by a 4.6-liter V8 biturbo engine developed from that of the RS Spyder. A similar engine already existed in the 918 super sports car. For use in the Porsche 963, the engine was designed to run on renewable fuels, among other things, and was given two powerful turbochargers. Together with the hybrid system, which for cost reasons is the same for all vehicles in the LMDh class, the Porsche 963 has a system output of around 680 hp and reaches a top speed of around 340 km/h, depending on the gear ratio.

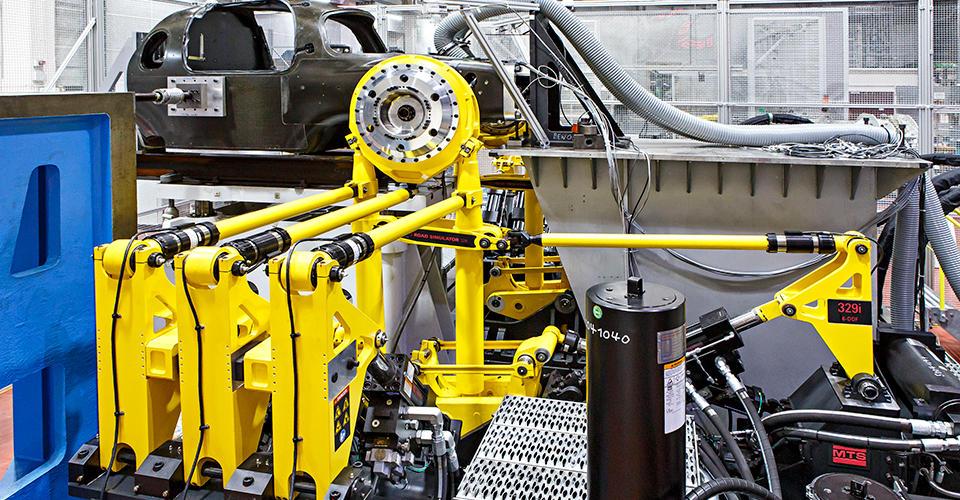

With these performance data, the safe functioning of safety-relevant structural components is all the more important. For the operational strength verification of the safety-relevant structural components, a sophisticated test technique is required that simulates the loads occurring in operation one-to-one in the laboratory. For this purpose, the Fraunhofer LBF uses a 12-channel axle test rig from MTS. Since the beginning of 2022, this new test stand (Model 329I) has replaced the predecessor model that was previously used successfully in Darmstadt for almost 20 years and significantly expands the testing possibilities. For example, the larger wheel sets of the test stand allow vehicles with wheel hub motors or with more powerful brake systems to be tested. It is also now possible to include real-time simulations "in the loop". The new laboratory equipment was procured as part of the ERDF measure "Smart Lab for Future Mobility Chassis Systems - SmartLab4Chassis" together with the Hessian Ministry of Science and Art and the Wirtschafts- und Infrastrukturbank Hessen. The laboratory equipment was specially optimized for testing high-performance and electrified new vehicle concepts for individual passenger transportation, including light vans and minibuses.

SmartLab4Chassis gefördert durch: