We accompany your development process for new wheels!

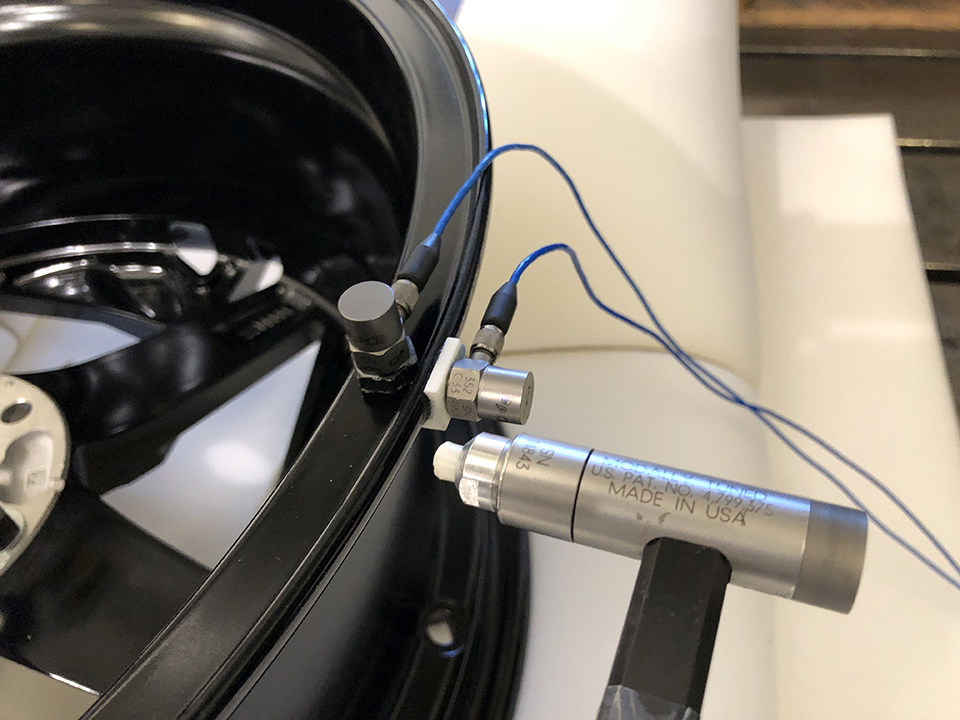

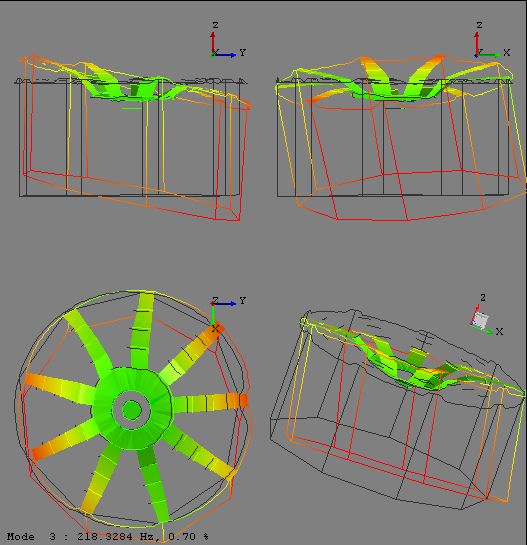

In the development process for new wheels, the structural dynamic properties are estimated by the suppliers using numerical models. To validate these properties, car manufacturers require experimental proof of these properties. For this purpose, the first newly manufactured wheels must be examined using methods of experimental structural dynamics according to special OEM specifications. Based on many years of experience, Fraunhofer LBF is familiar with these methods and the OEM's specifications. We offer wheel manufacturers the opportunity to carry out the required experiments to provide evidence.

In the development process for new wheels, the focus is increasingly shifting to structural dynamic properties, as their relevance is growing for the reason of new drive concepts, lightweight construction efforts and comfort. These properties, such as special natural frequencies or stiffnesses, are estimated by suppliers using numerical models. Car manufacturers require experimental proof of these properties for validation. For this purpose, the first newly manufactured wheels must be examined using experimental structural dynamics methods in accordance with special OEM specifications.

Based on many years of experience in the industry, Fraunhofer LBF is familiar with these methods and the OEM's specifications. Coupled with its in-depth knowledge of experimental and numerical structural dynamics and the available metrological equipment, Fraunhofer LBF offers to carry out the experimental investigations and provide the verification.

Known verification specifications include:

We offer wheel manufacturers for whom it is not worthwhile to build up the relevant expertise the opportunity to carry out the required experiments and provide the necessary evidence. As the service is provided independently of any wheel manufacturer or OEM, we have a wealth of experience across the industry as a basis for these projects.

Building up expertise in experimental structural dynamics and verification

The Fraunhofer LBF is also willing to support wheel manufacturers in building up expertise in experimental structural dynamics and verification in accordance with OEM specifications. To this end, the Fraunhofer LBF offers, for example, training courses, support in the selection of suitable measurement technology or assistance with initial projects.