Evaluation of unconventional process technologies for 7xxx series wrought aluminum alloys

The LOEWE project “ALLEGRO” aimed to develop efficient forming processes and welding methods for the realization of high-quality joints for high-strength 7xxx aluminum alloys (alloy system Al-Zn-Mg-Cu) using the example of the alloy EN AW-7075. The subprojects addressed the forming processes of roll forming and press hardening and the coating systems required for these processes, as well as structure integration using the joining techniques of laser beam welding, friction stir welding and magnetic pulse welding. The respective influence on the microstructure, quasi-static strength, structural durability and corrosion behavior was investigated.

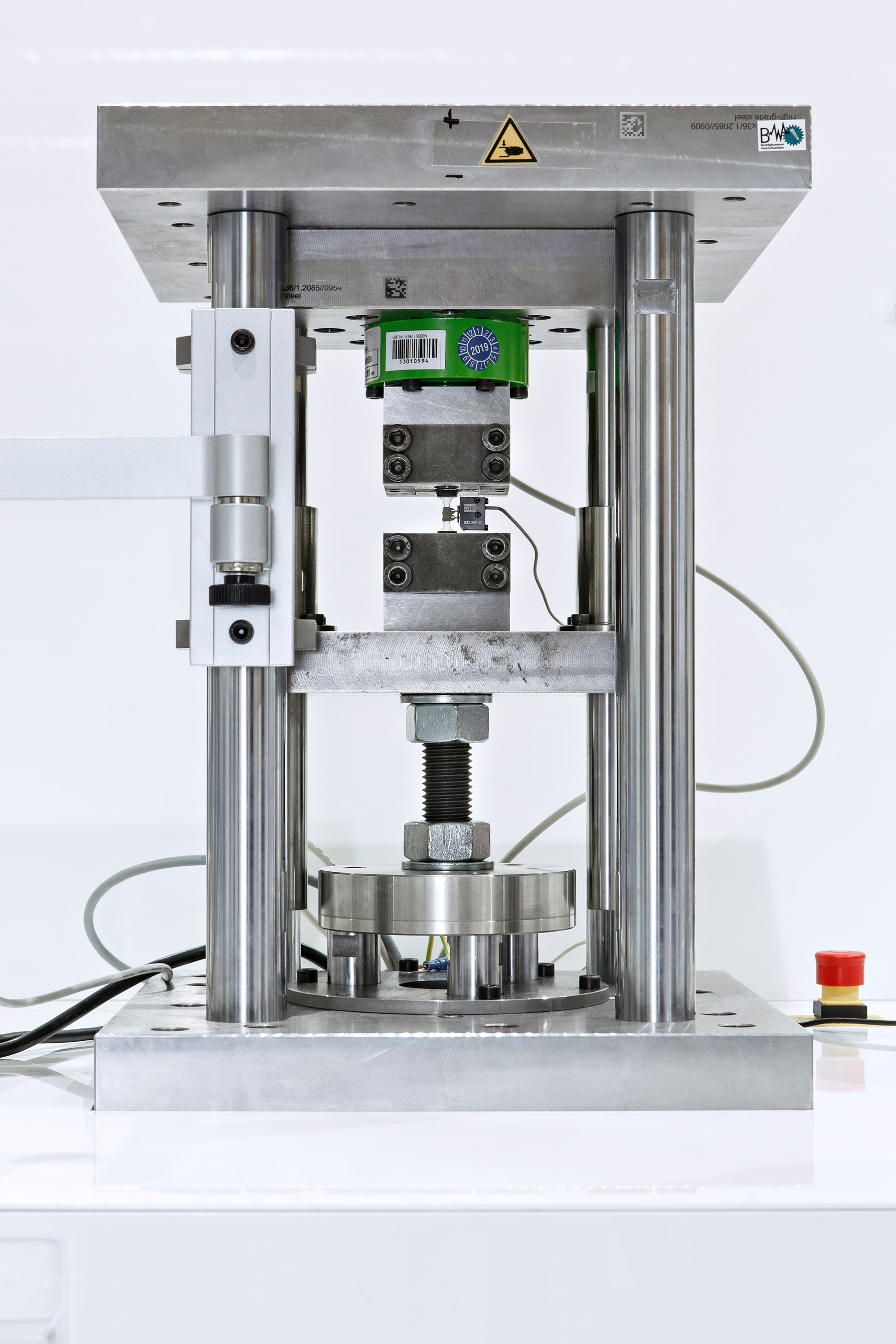

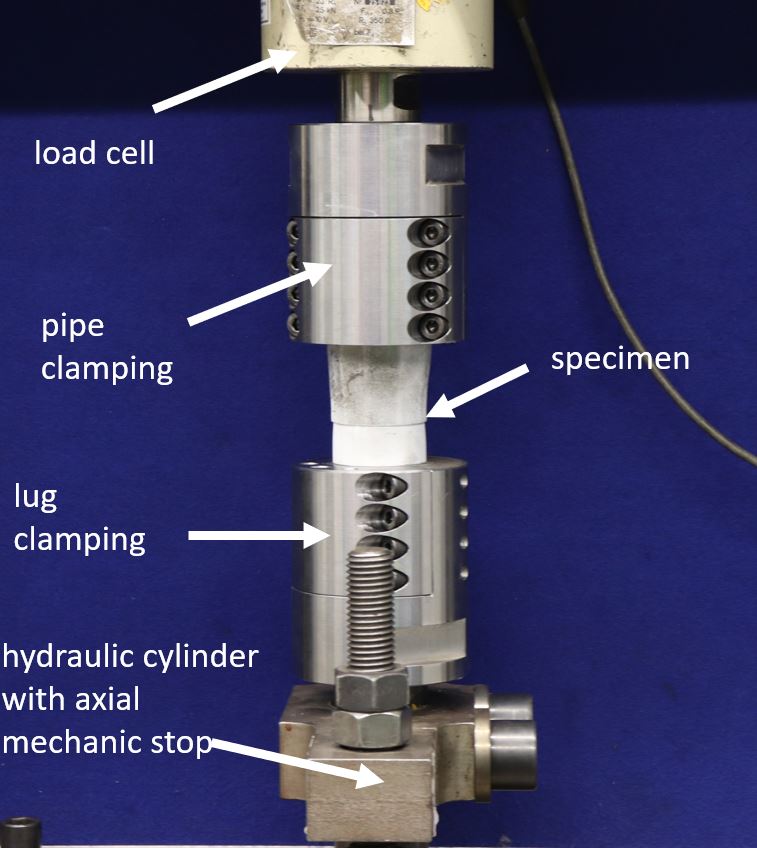

As part of the sub-project at Fraunhofer LBF, various manufacturing influences on the cyclic material and damage behavior of the aluminum alloy EN AW-7075 from the short-term to the long-term strength range were investigated. These include different heat treatment conditions, the influence of cold forming between solution annealing and artificial ageing ("W-temper" process route) and the weld-induced microstructural changes with and without subsequent heat treatment. In-house developed electro-mechanical and piezo-actuator small load test stands of Fraunhofer LBF were used. These enable energy-efficient experimental investigations on miniaturized and locally taken samples with a minimum length of 35 mm and a measuring cross-section smaller than 5 mm².

The developed technology demonstrator consists of a roll-formed pipe made of EN AW-7075, which was longitudinally welded by laser beam welding using an EN AW-7075 filler material strengthened with titanium carbide particles. Subsequently, the tube was welded in overlap by magnetic pulse welding onto a nodal connector made of AlSi10Mg additively manufactured by laser-based powder bedding process through a radially arranged field former.

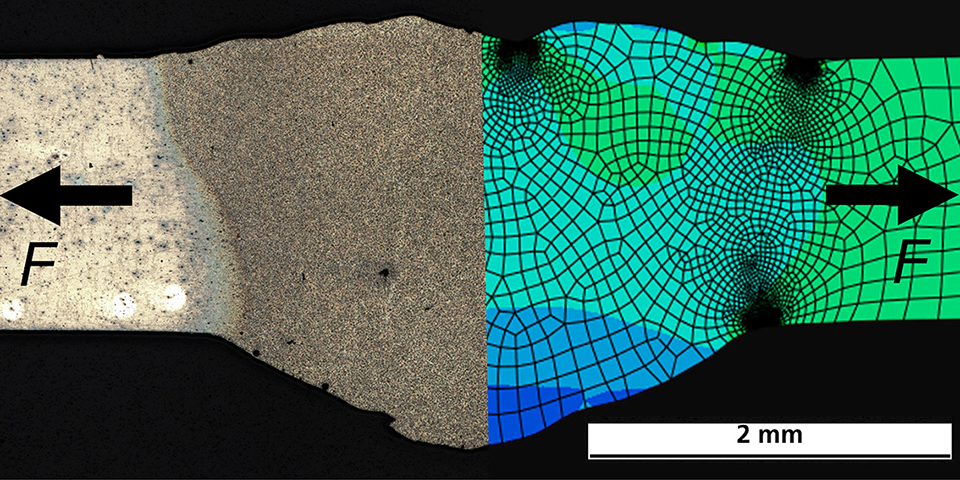

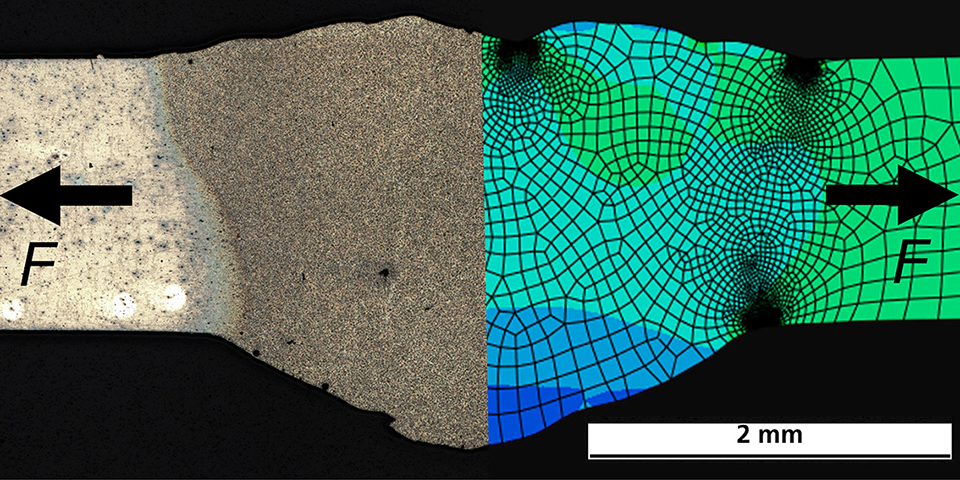

The simulation model was created by "reverse engineering" and based on 3D laser scans as well as metallographic cross-sections of the joining zone. Although the alloy EN AW-7075 is considered to be non-weldable and, moreover, according to the current state of research, dissimilar joints with additively manufactured structures often lead to defective joints, it was possible to demonstrate a joint quality that is in the range of conventionally weldable 5xxx and 6xxx wrought aluminum alloys by applying the notch stress concept with a reference radius of 0.05 mm.

Sponsor: Hessisches Ministerium für Wissenschaft und Kunst (LOEWE-Schwerpunkt)

Partner: Universität Kassel, Technische Universität Darmstadt